The Trend of Chassis Design.

Page 16

Page 17

If you've noticed an error in this article please click here to report it so we can fix it.

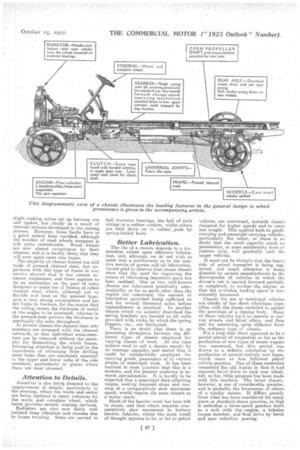

A Summary of General Tendencies, Including Notes on Engines, Clutches, Gearboxes, Final Drives, Brakes and Frames.

IN DEALING with a subject of this nature one cannot do anything but generalize, and as there have been comparatively few recent additions to the types of commercial vehicles which have been placed on the market—and these few of widely divergent natures—it is practically impossible to say that such and such a detail in design has, owing to its inclusion in a sufficient number of new vehicles, earned the right to be considered as the most up-to-date practice. However, taking as a basis those vehicles which have been placed on the market since 1918, it is possible to gain a general impression and to summarize certain tendencies.

The Power Unit.

In considering the various features of a chassis we will commence with the power unit and work back to the rear axle. Few startling modifications have been made in engine design. In the main the four-cylinder L-headed monobloc holds the field, although one or two power units with overhead valves have achieved a certain amount of popularity, and at least one six-cylinder model has been produced. More attention is now being paid to the question of carburation, particularly as regards the efficient. vaporization of fuel, and in this connection the hot-spot is being adopted in certain makes.

As regards clutches, there is a. marked tendency towards the cone type faced with bonded asbestos, although certain comparatively new machines employ the single-plate type, with a saw-steel disc running between rings of bonded asbestos. At first this type gave a small amount of trouble, owing to distortion of the disc through the clutch being intentionally slipped and, consequently, overheating, but. this trouble has now been almost entirely overcome, and, in our opinion, the single-plate clutch will become more and more popular. Practically all clutches are now provided with some form of clutch stop. Numerous patterns of universal joints are utilized on the shaft between the clutch and the gearbox, these ranging from the spur-gear type, in which a spur wheel with slightly rounded teeth meshes with a die cut with internal teeth, to the ordinary block-and-die type. The form which is gaining great popularity, and which can be used successfully where the angular movement is but slight, is the laminated steel disc.

Unit Construction.

Jr a few modern designs the gearbox, clutch and engine are contained in a single housing, but this has not yet become very popular amongst users, owing to fears regarding its inaccessibility, although in good designs we believe these fears to be quite unfounded, and one of the great advantages of this construction is that the alignment of the particular parts forming it is perfect, and arrangements can easily be made fnr ;lying efficient suspension at three points.

Whilst on this subject we may mention that in almost all modern vehicles threepoint suspension is employed for both engine and gearbox, either direct or through the medium of a sub-frame.

Gearboxes are becoming more or lees standardized in their general construction, the casing consisting usually of one casting with a lid, covering almost the whole of the top, and the various shafts being supported in bearings carried in detachable housings, so that the gears may be withdrawn without dismantling the whole box. There is a decided leaning towards the four-speed box, the proportion of four speeds to three beittg, roughly, three to one. Certain improvements can be noted in the change-speed operating gear, this being so arranged that no binding can occur clue to frame twist. Half-a-dozen or so vehicles are provided with central change, but this has not yet become very popular. Little progress has been made with silent-chain gearboxes, except for bus work, but for heavy chassis the constant-mesh principle is being adopted to a larger extent than formerly, the great advantage of this type over clash gears being that the change gear is practically foolproof, and the teeth cannot be chipped at their edges.

The Foot-brake Problem.

Opinion is divided regarding the position of the foot brake. In quite a number of vehicles either the loco. or internal-expanding type, with the shoes anchored to the gearbox, is still employed, but there is certainly a tendency towards arranging for both hand and foot brakes to act direct on the rearwheel .drums, as this relieves the transmission of considerable load, although it has the disadvantage that, unless carefully designed, not benefiting by the gear reduction, it does not give the same power as the gearbox type. It is mainly in vehicles with leather or fabric disc universal joints on the propeller shaft that it has been found advantageous to dispense with the gearbox brake, but the risk incurred by throwing the braking stresses on to these joints ha s been overcome in certain instances by arranging the foot brake either immediately in front of the axle or acting on a drum fastened to the tail end of the worm shaft. The only difficulty with either arrangement is that, unless very carefully designed, rattling may be set up by the connections and shoes, as, owing to its position, the brake is not sprung, the ouly cushion between it and the road being formed by the tyres. It would, however:seem an ideal arrangement for vehicles designed always to run on pneumatic tyres, and, although there are not many of these vehicles on the market, there is a decided tendency to adapt special chassis for the purpose. Quite a number of chassis embod3r tubular torque member with a short carder, shaft or merely a eniversal joint between it and the gearbox, but in many vehicles the Hotchkiss drive is employed,

although in some cases a small torque member a the plain type is employed.

We have already referred to the universal joints in connection with brakes. We would paint out that the Hardy disc type of joint is making rapid headway, as it is strong, silent and gives a long life if well treated.

The Final Drive.

So far as rear axles are concerned, worm drive has attracted an overwhelming number of adherents, although double-reductionaxles are giving very satisfactory service, and chain drive is still found useful on some heavy vehicles. In the majority of axles the casings .are of the pot type, practically always made in cast steel, but the forged banjo type is coming more and more into favour, both for double-reduction axles and those fitted with worm gear final drive. Very few axles are now made with the vertical drum central easipg and separate trumpet tubes, as these make the axle less accessible than is the case with the pot or banjo type, in which the worm gear and differential can usually be ro moved without dismantling the whole axle, or even removing the wheels. One or two very interesting types of axles have been designed in order to permit a large ground clearance under the centre of the casing. One particular axle which we have in mind embodies worm drive to the differential, the shafts of which are positioned above the driving shafts of the wheels, and each is provided with a spur pinion meshing with a spur wheel on the corresponding driving shaft. Large clearance is one feature in which the dual axle, with final drive to the road wheels through the medium of spur gearing, certainly has the advantage, although up to the present only one or two British vehicles utilize this form of construction.

cast-steel Wheels.

Over the last few years the number of vehicles fitted with cast-steel wheels has greatly exceeded the number fitted with other types; even now the ratio is something like three to one, but there is no doubt that the disparity will gradually disappear, partially for the reason that with the advent of pneumatic tyres steel disc wheels have become the vogue for this equipment, and partly for the reason that built-up steel wheels are rapidly being perfected and the troubles of hubcutting, rivet-shearing and the developing of general looseness ere being eliminated : in fact, in one particular wheel which we have in mind, and which we described recently, the discs are in compression in one direction and in tension in the other, so that loads applied to one portion are distributed throughout the In spite of this, however, there is little doubt that the cast-steel wheel will hold its own for a long time to come. Originally much trouble was experienced with cracks developing between the spokes and the rim, partly due to the slight rocking action set up between rim and spokes, but chiefly as a result of internal stresses developed in the caking process. However, these faults have to a great extent been rectified, although the number of steel wheels scrapped is still quite considerable. Wood. wheels are now almost conspicuous by their absence, and it is hardly likely that they will ever again come into vogue. The majority of chassis frames are still made of pressed channel steel, but experience with this type of frame in war service showed that it has certain inherent weaknesses, and there appears to be an inclination on the part of some designers to make use of frames of rolled channel steel, which, although not so flexible and neat as the pressed type, give a very strong construction and are not liable to fracture, for the reason that the rolling causes the thickness of metal at the angles to be increased, whereas in the pressed-steel pattern the thickness is practically the same throughout. In several e.hassis the channel-steel side members are arranged with the channel outwards, so that individual tross-memhers can he removed without the neces. sity for dismantling the whole frame. Increasingattention is being paid to the importance of refraining from drilling more holes than are absolutely essential in the upper and lower webs of the side members, particularly at places where these are most stressed.

Attention to Details.

Attention is also being directed to the improvement of details, particularly in the steering, where the worm and sector are being replaced in many instances by the worm and complete wheel, which latter provides several wearing surfaces. Radiators are alee now fairly well isolated from vibration and stresses due t,o frame twisting. Some are carried in hall trunnion bearings, the ball of each sitting in a rubber cushion, whilst others are held down on to rubber ,pads by spring-loaded belts.

Better Lubrication.

The life of a chassis depends to a tremendous extent upon adequate lubrication, and, although we do not wish to enter into a controversy as to the relative merits of grea;-e and oil lubrication, we are glad to observe that recent chassis show that the need for improving the means of lubricating important parts has been realized. One or two well-known chassis are lubricated praotically automatically, so far as parts other than the engine are concerned, tho amount of lubriCation provided being sufficient to last for several thousand miles before replenishment is required. In another chassis which WC recently described the spring brackets are formed as oil wells provided with wicks, by which the spring slippers, etc., are lubricated.

There is no doubt. that there is an increasing divergence between the different types of chassis employed for varying classes of work. At one time makers used to sell a chassis merely by its tonnage capacity, and stated that it could be satisfactorily employed for carrying goods, passengers or in various phases of municipal work. It has been realized in most quarters that this is a mistake, and the present tendency is towards specialization. It is hardly to be expected that a municipal dust-collecting wagon making frequent stops and running at a. comparatively slow maximum speed, would require the same chassis as a motor coach.

Much of the heavier work has been left to steam, and that which requires comparatively slow movement to battery electric vehicles, whilst the mails trend of thought appears to be, so far as petrol vehicles are concerned, towards chassis designed for higher speeds and to carry less weight. This applied both to goods. carrying and passenger-carrying vehicles, particularly the ]atter, as there is no doubt that the small capacity coach on pneumatics, or some satisfactory form of cushion tyre, will gradually oust the larger vehicles.

It must not be thought that the heavy side of petrol transport is being neglected, and much attention is being directed by certain manufacturers to the development of vehicles in which the driver's cab is carried forward partially or completely to enclose the engine, se that the available loading space is considerably increased. Chassis for use as municipal vehicles are chiefly of the short, wheelbase type. often with the frame curtailed to permit the provision of a tipping body. Many of these vehicles have to operate in narrow streets and blind alleys; and they call for something quite different from the ordinary type of chassis. For a long time there appeared to'be period almost of stagnation so far as the production of new typos of steam wagons was coneerned, but this period was drawn to a definite conclueion by the production Of several entirely new types, which snore or less followed petrol vehicle practice. One of these somewhat resembled the old Austin in that it had separate bevel drive to each rear wheel, but, so far, little progress has been made with this machine. The latest chassis, however, is one of considerable promise, and is probably the forerunner of others of a similar nature. It differs greatly from what has been considered for many years as standard steam practice, in thee it embodies a three-speed gearbox built as a unit With the engine/ a tubular torque member, and final drive by bevel and spur reduction gearing.