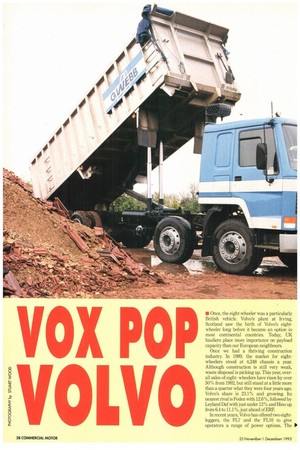

• Once, the eight-wheeler was a particularly British vehicle. Volvo's

Page 40

Page 42

Page 43

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

plant at Irving, Scotland saw the birth of Volvo's eightwheeler long before it became an option in most continental countries. Today, UK hauliers place more importance on payload capacity than our European neighbours.

Once we had a thriving construction industry. In 1989, the market for eightwheelers stood at 4,248 chassis a year. Although construction is still very weak, waste disposal is picking up. This year, overall sales of eightwheelers have risen by over 50% from 1992, but still stand at a little more than a quarter what they were four years ago. Volvo's share is 23.1% and growing. Its nearest rival is Foden with 12.6%, followed by Leyland Daf with just under 12% and Hino up from 6.4 to 11.1%, just ahead of ERR In recent years, Volvo has offered two eightleggers, the FL7 and the FL10 to give operators a range of power options. The

te smaller

engined FL7 is best suited to local tipping work while the bigger-cube FL10 is better for longer bulk haulage operations.

• EVOLUTION

Towards the end of 1985, the F7 eight-wheeler gave way to the low-height FL cab models. First the 8x4 FL10 appeared in September with its 9.6-litre charge-cooled straight-six rated at 223kW (299hp).

Two months later, the FL7 8x2 and 8x4 powered by a charge-cooled 6.7-litre sixcylinder engine rated at 183kW (245hp) made their entrance. They both used the same eight-speed synchromesh range-change gearbox. Less than three years later, at the beginning of 1988, it was replaced by the R1000 nine-speed box and R1400 14-speed transmission.

At the same time, the FL10 had an increase in power with the introduction of the TD102F engine. Although it was still 9.6 litres and six pots, output was 237kW (318hp). Against Volvo's better judgement, operators demanded an uplift in specification. It came in October 1990 with a heated suspension seat plus head restraints for the driver and electric windows.

At the same time, the FL7 received still more power-191kW (256hp) in the shape of the TD73ES while the FL10 with a revised TD102FM engine was rated at 231kW (310hp). The latter has since been superceded by the TD103ES producing 235kW (320hp) and sporting electronic diesel control. Both engines meet the Eum-1 emission standard.

Since the late 80s, the shorter and lighter Bride suspension has largely displaced the wider spread multi-spring 1-ride bogie suspension although it remains available.

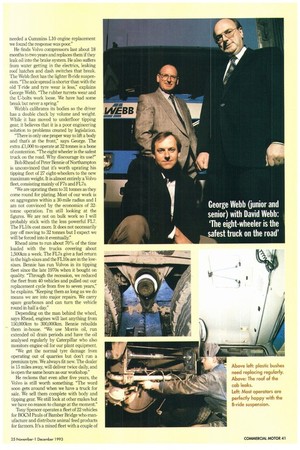

• OPERATORS

David and George Webb's mixed fleet of eightwheelers cover a high mileage. Once the company's operation concentrated on local site work in Cambridgeshire. Today the trucks travel much further afield and clock up some 80,000 miles a year each. The company, established by their father just before the second world war, has seventeen vehicles— three Foden 4000s, two Mercedes-Benz 30.25 and 12 Volvo FL7s and FL10s.

"We bought the Mercs secondhand when we needed a bit of extra capacity in a hurry. We've had to tighten up through the recession but we have just started to buy new again. The fleet will be heck to over 20 vehicles by the end of the year," George told CM

"The Fodens will run rings around our Volvos but we buy Volvos for the backup. Duffields are as good as you can get. Most of the trucks are serviced on contract maintenance but three are on preventative maintenance. At the moment there does not seem to be much between the costs of the two. With preventative maintenance, you could be faced with an unexpected bill if something major breaks. Contract maintenance means we predict our running costs more certainly.

"We uprated the FL7s to 31 tonnes and gained a half a tonne in payload. To maintain productivity on the full 32-tonne operation, we switched to the FUN with a sleeper cab. They are a bit quicker and carry a 27m3 body instead of a 25m3. But we had to go to underfloor tip gear to get the weight distribution," says George.

Webb has bought Volvos for a good number of years but not without a break. "We fell out over the torque converters on some F7s back in 1979," explains George. "They were the early automatics before the current Geartronic. We were having serious problems with clutch wear and downtime. Volvo didn't want to know. Allison got to hear of our plight, but we had sold most of them by then. They changed the boxes on our last three. We bought seven or eight Leyland Dais after that.

"Reliability is unbelievably good today. We get a bit of wear in the propshaft UJs. The plastic bushes used in the kingpins wear— they should be bronze. Because we are keeping them longer, mileage is high. We have three E-registered FL7s that have done over half a million miles and we have not had to touch the engines yet. When we do need an engine, the truck will be turned round in 24-hours. But seven months ago, when we

needed a Cummins L10 engine replacement we found the response was poor."

He finds Volvo compressors last about 18 months to two years and replaces them if they leak oil into the brake system. He also suffers from water getting in the electrics, leaking roof hatches and dash switches that break. The Webb fleet has the lighter B-ride suspension. "The axle spread is shorter than with the old T-ride and tyre wear is less," explains George Webb. "The rubber turrets wear and the 1.3-bolts work loose. We have had some break but never a spring."

Webb's calibrates its bodies so the driver has a double check by volume and weight. While it has moved to undedloor tipping gear, it believes that it is a poor engineering solution to problems created by legislation.

"There is only one proper way to lift a body and that's at the front," says George. The extra £1,000 to operate at 32 tonnes is a bone of contention. "The eight wheeler is the safest truck on the road. Why discourage its use?"

Bob Rhead of Peter Bennie of Northampton is unconvinced that it's worth uprating his tipping fleet of 27 eight-wheelers to the new maximum weight It is almost entirely a Volvo fleet, consisting mainly of F7s and FL7s.

"We are uprating them to 31 tonnes as they come round for plating Most of our work is on aggregates within a 30-mile radius and I am not convinced by the economics of 32tonne operation. rm still looking at the figures. We are not on bulk work so I will probably stick with the less powerful FL7. The FL1Os cost more. It does not necessarily pay off moving to 32 tonnes but I expect we will be forced into it eventually" Rhead aims to run about 70% of the time loaded with the trucks covering about 1,5001un a week. The FL7s give a fuel return in the high-sixes and the FL1Os are in the lowsixes. Bennie has run Volvos in its tipping fleet since the late 1970s when it bought on quality. "Through the recession, we reduced the fleet from 40 vehicles and pulled out our replacement cycle from five to seven years," he explains. "Keeping them as long as we do means we are into major repairs. We carry spare gearboxes and can turn the vehicle round in half a day."

Depending on the man behind the wheel, says Rhead, engines will last anything from 150,000km to 300,000km. Bennie rebuilds them in-house. "We use Morris oil, run extended oil drain periods and have the oil analysed regularly by Caterpillar who also monitors engine oil for our plant equipment.

"We get the normal tyre damage from operating out of quarries but don't run a premium tyre. We always fit new. The dealer is 15 miles away, will deliver twice daily, and is open the same hours as our workshop."

He reckons that even after five years, the Volvo is still worth something. "The word soon gets around when we have a truck for sale. We sell them complete with body and tipping gear. We still look at other makes but we have no reason to change at the moment."

Tony Spencer operates a fleet of 22 vehicles for BOCM Pauls of Bamber Bridge who man ufacture and distribute animal feed products for farmers. It's a mixed fleet with a couple of

inherited ERFs 110 and Seddon Atkinsons and includes nine eight-wheelers. including FL7s and FL10s. "The eight-wheeler gives the best compromise between access and weight and is a major factor in the choice of vehicle. We buy Volvos principally for the dealer service back-up," says Spencer.

In pure hardware terms, he says, there is not a lot to choose between the different makes. He keeps trucks for about seven years; that's another reason for buying Volvos. "The engines are meaty enough to stand up to the work. We operate tipper blowers so the engines do 30-40% more work than the 120,000km on the clock indicates. Fuel consumption is important to us but it will mean little to you in terms of mpg."

In his time at BOCM PauIs, he has had to change only two gearboxes across the whole fleet and never had to rebuild an engine. All the vehicles are on contract maintenance, except for the late ones which are on contract hire through the local dealer and Volvo. "Thomas Hardy gives us very good service maintaining our vehicles overnight and at week ends and getting them back into service the next day," says Spencer.

Four of his Volvo eight-wheelers are 8x2s with lift-up rear axles to give extra manoeuvrability through farm gates that were designed to give access to a horse and cart.

Fitting Pirelli and Goodyear tyres eliminated tyre shouldering. "We then found we were getting a lot of shoulder wear on the tyres fitted to the second steer axle. We were having to replace them at twice the rate of the front steer axle."

To its credit, he says, Volvo stepped in and quickly solved the problem. With the steering geometry set up for eight wheels, lifting the rear axle put an extra load on the second steering axle. "We have had no trouble since the steering angles were reset. Uprating to 32 tonnes is not an option with the lift axle but we will take advantage of it with new vehicles."

He has never had a problem selling Volvos. "Normally we sell to the trade or to third parties contracted to us. In terms of reliability and time on the road, the Volvos are better than other makes of vehicles in our fleet"

• DEALERS

Ian Thompson, sales manager for Volvo main dealer, Darlington Commercials sells FI.7 and FL10 eight-wheelers in about equal numbers. The construction market may be still declining but you can't get a good used eightlegger for love or money Even until last year, there were good late secondhand examples about Thompson says. He is still on the look out for them but the supply has almost dried up. "The condition of the body and the tip-gear mountings are points to look for," says Thompson. "Otherwise, the general appearance will be a good indication of how hard it's been worked. Some operators have uprated the FL7 260s to 32 tonnes. The B-ride bogie is quite adequate for normal on/off road use. It's generally operators on waste disposal work that go for the 1-ride. Day cabs were mainly specified on the FL7s and sleeper cabs for the FL10s. With the move towards articulated vehicles for long haul tipping operations, I would say the majority of operators are fitting day cabe

Tony Ferguson of Junction Ten Commercials, part of the Hartshorn group, specializes in used Volvos. He usually has about 30 trucks in stock which generally includes three or four eight wheelers. "Owner operators buy them because of the weight, ride and pulling power," he told CM "The ride is one of the best and Volvo is good on parts and back-up. They are in great demand in the Midlands with the Black country route being built."

Good ones are few and far between, he admits, "When we get one, it doesn't stay long. Some times I've sold them on before they have come into the yard. Wilcox are still regarded as the best bodies."

He finds there are operators who look after trucks and those that don't. "They are either very good or absolute rubbish. At the moment I have a list of people looking for sixwheelers, never mind eight-wheelers. They can't carry as much but they can get into sites that are difficult with an eight-wheeler."

CAP quotes a 'clean' F-reg FL7 6x4 at around £18,000; an average model will run out at £15,750. An FLIO on the same plate can command up to £22,000 for a clean model with around 200,000km on the clock falling to £15,000 for a well worn chassis.

• SUMMARY

If as one operator argues, there is little difference in the quality of the hardware, there must be another reason why Volvo sells almost twice as many eight-wheelers as any one else in the UK. The answer that comes through, loud and clear, time after time, is service backup at both local and national level.

The smaller-engined FL7 has been criticised for lack of power but CM'S Road Tests show that with the latest power ratings, they need only be marginally slower than the more powerful FL10.

For longer hauls, the FL10 with sleeper-cab tends to become the more popular choice and engine life never seems to be in question. Uprating to 32 tonnes is a matter which individual operators will ponder.When faced with buying new, most operators seem prepared to bite the bullet and pay the extra £1,000 VED—not the least when it's a Volvo. E by Bill Brock