Proportioning Braking Force to Weight Transference

Page 40

If you've noticed an error in this article please click here to report it so we can fix it.

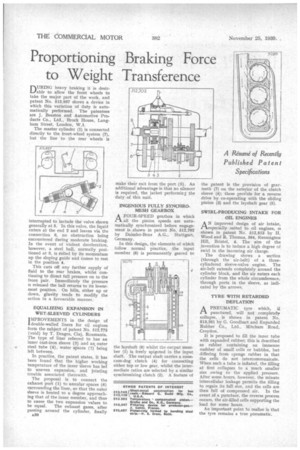

DURING heavy braking it is desirable to allow the front wheels to take the major part of the work, and patent No. 513,937 shows a device in which this variation of duty is automatically performed. The patentees are J. Beeston and Automotive Products Co., Ltd., Brock House, Langham Street, London, W.1.

The master cylinder (1) is connected directly to the front-wheel system (7), but the line to the rear wheels is interrupted to include the valve shown generally at 5. In this valve, the liquid enters at the end 2 and leaves via the connection 6, no obstruction being encountered during moderate braking. In the event of violent deceleration, however, a steel ball, normally positioned at 3, is rolled by its momentum up the sloping guide and comes to rest in the position 4.

This cuts off any further supply of fluid to the rear brakes, whilst continuing to direct full pressure on to the front pair. Immediately the pressure is released the ball returns to its lowermost position. On hills, either up or down, gravity tends to modify the action in a favourable manner.

EQUALIZING EXPANSION IN WET-SLEEVED CYLINDERS

IMPROVEMENTS in the design of double-walled liners for oil engines form the subject of patent No. 512,775 (void) by T. Dragos, Cluj, Roumania. The type of liner referred to has an inner cast-iron sleeve (3) and an outer steel tube (4), water spaces (2) being left between.

In practice, the patent states, it has been found that the higher working temperature of the inner sleeve has led to uneven expansion, and jointing trouble associated therewith.

The proposal is to connect the exhaust port (1) to annular spaces (6) surrounding the liner, so that the outer sleeve is heated to a degree approaching that of the inner member, and thus to cause the two expansion values to be equal. The exhaust gases, after passing around the cylinder, finally A30 make their exit from the port (5). An additional advantage is that no silencer is required, the jacket performieg the duty of this unit.

INGENIOUS FULLY SYNCHROMESH GEARBOX A FOUR-SPEED gearbox in which Pl. all the pinion speeds are automatically synchronized before engagement is shown in patent No. 512,702 by Daimler-Benz A.G., Stuttgart, Germany.

In this design, the elements of which follow normal practice, the input member (8) is permanently geared to the layshaft (6 whilst the output member (1) is free y spigoted in the input shaft. The output shaft carries a conecum-dog clutch (4) for connecting either top or low gear, whilst the intermediate ratios are selected by a similar synchronizing clutch (2). A feature of

the patent is the provision of gearteeth (7) on the exterior of the clutch sleeve (4); these pro4ide for a reverse drive by co-operating with the sliding pinion (3) and the layshaft gear (5).

SWIRL-PRODUCING INTAKE FOR OIL ENGINES

AN improved design of air intake, especially suited to oil engines, is shown in patent No. 512,813 by H. Wood and R. Thomas, 564, Kensington Hill, Bristol, 4. The aim of the invention is to induce a high degree of swirl in the incoming air charge.

The drawing shows a section (through the air-belt) of a threecylindered sleeve-valve engine. The air-belt extends completely around the cylinder block, and the air enters each cylinder from the whole circumference. through ports in the sleeve, as indicated by the arrows.

TYRE WITH RETARDED DEFLATION

APNEUMATIC tyre which, if punctured, will not completely collapse, is shown in patent No. 513,261 by G. Goodhart and Expanded Rubber Co., Ltd., Mitcham Road, Croydon.

It is proposed to fill the inner tube with expanded robber; this is described as rubber containing an immense number of small cells or bubbles, but differing from sponge rubber in that the cells do not intercommunicate. When such a tube is inflated, the filling at first collapses to a much smaller size owing to the applied pressure. After some hours, however, the minute intercellular leakage permits the filling to regain its full size, and the cells are then full of compressed air. In the event of a puncture, the reverse process occurs, the air-filled cells supporting the load for some hours.

An important point to realize is that the tyre remains a true pneumatic.