T here are a number of T here are a number of

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

occupational hazards for hauliers working in the construction sector First, there's day-to-day wear and tear—tippers have a tough life on rough sites. Mark Williams says: ''We check the tyres of each vehicle every night: we have four fitters and two apprentices who fit the tyres. They check the vehicles so they are ready to go out next day." And constant attention has to be paid to springs, he adds.

For Neil Williams Haulage, a massive 90% of tipper work involves taking materials—chiefly unwanted topsoil—from the construction site; just 10% of work is taken up in deliveries.

Just before CM leaves the depot, Williams mentions a problem which, although frequently experienced by many hauliers. is especially prevalent when dealing with the construction industry: late payment. "Ft takes between BO and 90 days to get paid after we have invoiced the company," he reports. It is the curse of red tape which prolongs payment, and the process can be a long one. Prices often need to be negotiated more than once. Williams says a construction company may initially agree the necessary work and the corresponding price, but when a project is under way the site manager might require more sand, for example.

That site manager might be in Glasgow, but his head office could be in London. Crucially, the need for more service from the haulier means that the original rate is obsolete—the already long payment process must start all over again.

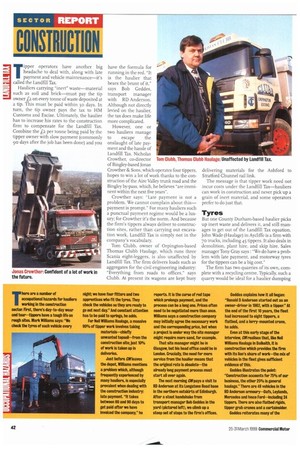

The next morning CM pays a visit to RD Anderson at its Longstone Road base in the northern outskirts of Edinburgh. After a stout handshake from transport manager Bob Geddes in the yard (pictured left), we climb up a steep set of steps to the firm's offices.

Geddes explains how it all began: "Ronald 0 Anderson started out as an owner-driver in 1962, with a tipper" At the end of the first 10 years, the fleet had increased to eight tippers, a flatbed, and a lorry-mounted crane, he adds.

Even at this early stage of the interview, CMrealises that, like Neil Williams Haulage in Dalkeith, it is construction which provides the firm with its lion's share of work—the mix of vehicles in the fleet gives sufficient evidence of this.

Geddes illustrates the point: "Construction accounts for 750/a of our business, the other 25% is general haulage," There are 48 vehicles in the RD Anderson armoury—Dafs, Leylands, Mercedes and Iveco Ford—including 24 tippers. There are also flatbed rigids, tipper grab cranes and a curtainsider.

Geddes reiterates many of the points made by Mark Williams about haulage and the construction industry. "There is so much happening in construction," he says, "it is very busy at the moment in Edinburgh. I think in general there is a boom in the UK."

He also tells of the benefits of having a large tipper fleet, explaining that many of the smaller tipper operators in the Edinburgh region have gone out of business: "There used to be about 30 members in the Edinburgh and District Tipper Association, but now there are only 22."

Like Neil Williams Haulage, RD Anderson operates chiefly in the Edinburgh area. "The bulk of our tipper work is excavation, and we carry stone from quarries to building sites," says Williams. Most of our work is residential." The firm's cranes are often used on construction sites, lifting cumbersome objects such as accommodation blocks.