Low-cost Air Suspension By Dunlop%

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

INCORPORATING conventional air-spring units, a system has been developed by the suspension department of the Dunlop Rubber Co., Ltd., FoieShill, Coventry, to replace the standard ,rear springs of 30-cwt.-7-ton chassis without major modifications to the existing frame members.

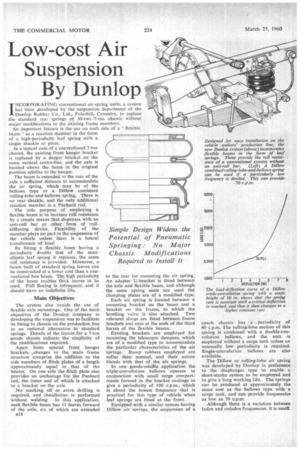

An important feature is the use on each side of a ' flexible beam" as a reaction member in the form of a high-periodicity leaf spring with a single shackle or pivot.

In a typical case of a conventional 7-ton chassis, the existing front hanger bracket is replaced by a deeper bracket on the same vertical centre-line, and the axle is located above the beam in the original position relative to the hanger.

The beam is extended to the rear of the axle a sufficient distance to accommodate the air spring, which may be of the bellows type or a Dillow combined rolling-lobe-and-bellows spring. There is no rear shackle, and the only additional reaction member is a Panhard rod.

The sole purpose of employing a flexible beam is to increase roil resistance by a simple means that dispenses with an anti-roll bar or other form of rollstiffening device. Flexibility of the member plays no part in the suspension of the vehicle unless there is a lateral transference of load.

By fitting a flexible beam having a periodicity double that of the semielliptic leaf spring it replaces, the same roll resistance is provided. Mareover, a beam built of standard spring leaves can be constructed at a lower cost than a conventional box beam. The high periodicity of the beam enables thick leaves to be used. Full flexing is infrequent, and it should have an indefinite life.

Main Objectives

The system also avoids the use of flexible axle mountings. One of the main objectives of the Dunlop company in developing the suspension was to facilitate its fitting to chassis on the production line as an. optional alternative to standard springs. Details of the layout for a 7-ton goods chassis indicate the simplicity of the modifications required.

Apart from special front hanger brackets, ,changes to the main frame structure comprise the addition to the side members of flitch plates of a length approximately equal to that of the beams. On one side the flitch plate also provides an anchorage for the Panhard rod, the inner end of which is attached to a bracket on the axle.

No marking off or extra drilling is required, and installation is performed without welding. In this application, each flexible beam has II leaves forward of the axle, six of which are extended to the rear for mounting the air spring. An adapter U-bracket is fitted between the axle and flexible beam, and although the same spring seats are used the clamping plates are of a modified type.

Each air spring is located between a mounting bracket on the beam and a bracket on the frame, to which the levelling valve is also attached. Two rebound slings are fitted between frame brackets and eyes at the ends of the third leaves of the flexible beams.

Existing brackets are employed for mounting the telescopic dampers, which are of a modified type to accommodate the particular characteristics of the air springs. Bump rubbers employed are softer than normal, and their action blends with that of the air springs.

In one goods-vehiEle application the triple-convolution bellows operate in conjunction with small surge compartments formed in the bracket castings to give a periodicity of 100 c.p.m., which is about the lowest frequency that is practical for this type of vehicle when leaf springs are fitted at the front.

Equipped with a similar system having Dillow air springs, the suspension of a coach chassis has a periodicity of 80 e.p.m. The rolling-lobe section of this spring is combined with a double-convolution bellows, and the unit is employed without a surge tank unless an unusually low periodicity is required. Single-convolution bellows are also available.

The Dillow or rolling-lobe air spring was developed by Dunlop in preference to the diaphragm type to enable a short-stroke system to be employed and to give a long working life. The springs can be produced at approximately the same cost as the bellows type with a surge tank, and can provide frequencies as low as 70 c.p.m.

Although there is a variation between laden and unladen frequencies, it is small. In a typical case, a laden frequency of 90 c.p.m, compares with an unladen frequency of 100 c.p.m.

When a load is initially applied to the spring a self-sealing piston moves upwards into the rolling-lobe section, the effective

rXPANDED metal, commercial pro

duct of the technique of cutting sheet material and stretching it into a mesh formation, is used for a variety of applications throughout the motor industry.

Mini-mesh--a microscopic variety of expanded metal, with apertures as small as 0.75 mm.—is used to make the " gauze " air intakes and air cleaners on many Amal carburetters. Filters built into windscreen-washer units made by Tudor Accessories, Ltd., Beaconsfield Road, Hayes, Middx., are also made from mini-mesh.

The tiny diamond pattern is also cut and expanded on such metals as diameter of which remains substantially constant by virtue of the restraining action of a bell-mouthed coot our plate or skirt. The shape of the skirt can be varied to modify the spring characteristics •to meet individual requirements.

With further movement of the piston; the rubber of the clamping ring makes contact with the skirt ring, and additional deflection is accommodated by the bellows section. An increase in load expands the bellows and the effective area of the unit, thus raising the rate of the spring when deflection exceeds a critical limit, This favourable characteristic of the system is shown in the load-deflection curve of a Dillow 10-in, triple-convolution spring having a static height of 101 in: It will be seen that the rate remains constant until the deflection exceeds a critical limit, and that it then increaies to a higher constant value for the remainder of the deflection curve.

Although the operating principle of the latest Dunlop levelling valve is similar to that of the former type, various improvements have been introduced aluminium, brass, copper, stainless steel, gold, silver a n d platinum. Nylon and p.v.c. plastics are also subjected to similar treatment for a variety of uses.

In this respect the manufacturers. such as the Expanded Metal Co., Ltd., 16 Caxton Street, London, SW.]., claim that expanded sheet material is cheaper than woven wire mesh—and has the added advantage of being fray-resistant.

Probably the most common use of expanded metal in commercial vehicles is for radiator grilles. Air-intake covers of expanded metal are made in large numbers by Coopers Mechanical Joints, Ltd., Abergavenny.

The material is also used in the constant war against petty pilfering and many Morris 5-cwt. vans run by G.P.O. engineers have a grille behind the driver's seat to prevent the loss of small tools. It has saved much expense and trouble.

Several years before expanded steel fencing was used as an anti-dazzle medium on Ml, the principle of diffusing light by angled mesh had been exploited in a different way. Designers had been alarmed by the amount of wind resistance caused by external sun visors.

They wanted a visor which effectively blocked overhead rays but did not trap the wind. The problem was answered by which enable the restricter valve to be adjusted more accurately and this gives a longer working life.

By increasing the size of the orifices in the hydraulic damping section of the unit, and the volume of oil that is displaced with movement of the piston, the flow of oil can be varied to cater for particular needs within precise limits.

In place of the torsion spring incorporated in the original design to provide delayed action of the air valve, a helicalcoil spring is now used which is more reliable and cheaper to produce. An operating lag of 8-15 sec. is normally employed.

Of particular interest because of its

simplicity,. the modified air-valve operating lever is bonded to a rubber mounting which forms the pivot as well as a seal. The lever is operated by the piston sleeve at its inner end, whilst its outer end actuates the air valves. Known as a pivot-seal, the unit replaces a far more complicated spindle and lever system.

A notable feature of the modified airvalve system is the use of fluted-nylon thrust pins, the flutes of which act as air passages. Nylon is also employed for the body of the air-valve section, which affords the advantage that the body and valve seats can be moulded in one piece.

the employment of expanded metal, which was even more advantageous because it allowed greater visibility than a sheet steel visor, and eliminated shadows inside the vehicle.

Vauxhall Motors, among other manu. facturers, now fit non-slip expanded metal to cab steps and door sills in Bedford vehicles, in place of rubber mats, which were inclined to lift and cause potential danger.

Facing a similar problem were manufacturers of tankers. They had, in many cases, to provide a cat-walk along the top of the tank, but it had to have a non-slip surface, and, even more vital, be made of material which would not cause a spark and ignite highly inflammable loads. The solution came in the form of heavy-gauge expanded aluminium.

Easy forming qualities of the material from the sheet have aided the bodybuilder in the construction of insulated vans. Two layers of expanded metal, supported by a wooden frame, have been used to encase insulating material, such as glasswool. This base has been hidden by outer and inner skins.

In a rather different application the material has been used to form the basic shape of car bodies. This is then covered with glass-fibre to produce a plastics body, Commercial bodybuilders are expected to adopt this technique. .

Expanded-metal rectangles of +-in. mesh, measuring 2 ft. by 1 ft.. have been successfully used to enable heavy vehicles to gain their freedom from icy patches.