Eo m Drivers &Mechanics

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS WEEKLY is paid for the best communication received, and one penny a line of ten words for anything else published, with an allowance for photographs.

Send us an account of any sPecial incident of your work or experience. If suitable, Tve will edit your notes, sup/Ay a sketch when required, and pay you for everything published. Mention your employer's name, In confidence, as evidence of good faith. Address to The Editor, THB COMMERCIAL MOTOR, Rosebery Avenue, London, E.G.

Light Up your Lamps At 7.19 on Thursday ; 7.21 on Friday ; 7.23 on Saturday; 7.26 on Monday ; 7.27 on Tuesday ; 7.28 on Wednesday.

Domes of Silence. Case-hardening.

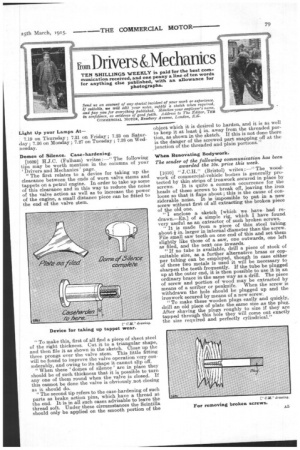

[1609] H.J.C. (Fulham) writes :—" The following tips may be worth mention in the columns of your 'Drivers and Mechanics' page. "The first relates to a device for taking up the clearance between the ends of worn valve stems and tappets on a petrol engine. In order to take up some of this clearance and in this way to reduce the noise of the valve action as well as to increase the power of the engine, a small distance piece can be fitted to the end of the valve stem.

"To make this, first of all find a piece of sheet steel of the right thickness. Cut it to a triangular shape, and then file it as shown in the sketch. Close up the three prongs over the valve stem. This little fitting will be found to improve the valve operation very considerably, and owing to its shape it cannot slip off. "When these 'domes of silence' are in place they should be of such thickness that it is possible to turn any one of them round when the valve is closed. If this cannot be done the valve is obviously not closing as it should do.

"The second tip refers to the ease-hardening of such parts as brake action pins, which have a thread at the end. It is in all such cases advisable to leave the thread soft. Under these circumstances the Scintilla should only be applied on the smooth portion of the object which it is desired to harden, and it is as well to keep it at least in. away from the threaded portion, as shown in the sketch. If this is not done there is the danger of the screwed part snapping off at the junction of the threaded and plain portions."

When Renovating Bodywork.

The sender of the following communication has been awarded the Ws. prize this week.

[1610] " J.C.H." (Bristol) writes :—" The woodwork of commercial-vehicle bodies is generally protected by thin strips of ironwork secured in place by screws. It is quite a common occurrence for the heads of these screws to break off, leaving the iron loose so that it flaps about ; this is the cause of considerable noise, it is impossible to put in a new screw without first of all extracting the broken piece of the old one.

"I enclose a sketch [which we have had redrawn.—En.] of a simple rig, which I have found very useful as an extractor of such broken screws.

"It is made from a piece of thin steel tubing about ir in. larger in internal diameter than the screw. File small saw teeth on one end of this and set them slightly like those of a saw, one outwards, one left as filed, and the next one inwards.

'If no tube is available, drill a piece of stock of suitable size, as a further alternative brass or copper tubing can be employed, though in case either of these two metals is used it will be necessary to sharpen the teeth frequently. If the tube be plugged up at the outer end, it is then possible to use it in an ordinary brace in the same way as a drill. The piece of screw and portion of wood may be extracted by means of a scriber or penknife. When the screw is withdrawn the hole should be plugged up and the ironwork secured by means of a new screw.

"To make these wooden plugs easily and quickly, drill an old piece of plate the same size as the plug. After shaving the plugs roughly to size if they are tapped through this hole they will come out exactly the size required and perfectly cylindrical."