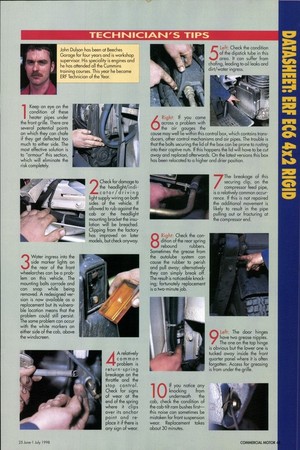

TECHNICIAN'S TIPS John Dulson has been at Beeches Garage for

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

four years and is workshop supervisor. His speciality is engines and he has attended all the Cummins training courses. This year he became ERF Technician of the Year.

1 Keep an eye on the condition of these heater pipes under the front grille. There are several potential points on which they can chafe if they get deflected too much to either side. The most effective solution is to "armour" this section, which will eliminate the risk completely. 2 Check for damage to the headlight/ind i ea tor /d r i vi ng light supply wiring on both sides of the vehicle. If allowed to rub against the cab or the headlight mounting bracket the insulation will be breached. Clipping from the factory has improved on later models, but check anyway.

Water ingress into the side marker lights on the rear of the front wheelarches can be a problem on this vehicle. The mounting bolts corrode and can snap while being removed. A redesigned version is now available as a replacement but its vulnerable location means that the problem could still persist. The same problem can occur with the white markers on either side of the cab, above the windscreen. 4 A relatively common problem is return-spring breakage on the throttle and the stop control. Check for signs of wear at the end of the spring where it clips over its anchor point and replace it if there is any sign of wear. 5 Left: Check the condition of the dipstick tube in this area. It can suffer from chafing, leading to oil leaks and dirt/water ingress.

6 Right: If you come across a problem with the air gauges the cause may well lie within this control box, which contains transducers, other control mechanisms and air pipes. The trouble is that the bolts securing the lid of the box can be prone to rusting into their captive nuts. If this happens the lid will have to be cut away and replaced afterwards. On the latest versions this box has been relocated to a higher and drier position.

7The breakage of this securing clip, on the compressor feed pipe, is a relatively common occurrence. If this is not repaired the additional movement is likely to result in the pipe pulling out or fracturing at the compressor end.

8 Right' Check the condition of the rear spring rebound rubbers. Sometimes the grease from the autolube system can cause the rubber to perish and pull away; alternatively they can simply break off. The result is noticeable knocking; fortunately replacement is a two-minute job. Et The door hinges have two grease nipples. The one on the top hinge is obvious but the lower one is tucked away inside the front quarter panel where it is often forgotten. Access for greasing is from under the grille.

If you notice any knocking from underneath the cab, check the condition of the cab-tilt ram bushes first— this noise can sometimes be mistaken for front suspension wear. Replacement takes about 30 minutes. 1