RADIATOR REPAIRS.

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

Some Useful Contributions from Our Driver and Mechanic Readers.

THE RADIATOR is, perhaps, the most vulnerable part. of a motor vehicle.At least, it is most liable to suffer injury whenever a collision • occurs. Moreover, its constitution is not, too robust, and it therefore follows that it suffers With corresponding frequency. For all that, however, letters describing such repairs are few and far between, a circumstance which would rather seem to show either that, the majority of drivers and mechanics are not capable of effecting radiator repairs, or that, when accidents do happen, the damage is generally so serious that resort either to the manufacturer or to those who specialize in such work becomes advisable or even necessary.

Additional colour is lent to this view by the fact that the most interesting letter this week, the one which has been judged worthy of the 15s. prize, is written by a man who, although not actually employed by such a firm, Is quite a specialist in tinsmith'a work, within which category most radiator repairs are included.

The fracture the repair of which is the subject of his letter in an unusual one, which circumstance is a contributory cause of our selecting this letter for honours. It occurred in connection with the tube plate of a tubular radiator, eerhich was broken in two along a line of bolt and tube holes, as shown by the accompanying sketch. The tubes of the radiator were also damaged, but their renewal was a matter of small moment, spares being habitually stocked. The tube plate was not replaceable at short notice, as none was in stock, and it would have meant, at least a day's delay to have waited while a new one was procured from the makers. The writer of the letter--" A.E.," of Manchester.—resorted to bracing, which he carried out as follows :—

The broken surfaces were, as an essen, tial preliminary, thoroughly scraped and cleaned. The two parts were then secured together, using the existing bolt holes, by means of a couple of strips of

bar iron I in by in., the bars being arched over the fracture So as to leave clear access to the jointfor brazing. The brazing metal was then prepared, a mixture of zinc and copper filings being used, in the proportions of two of the former to one of the latter. The flux used was pure calcined borax ; this is a borax powder which has been heated until practically all the water has been driven off.

The damaged plate was placed on firebricks and heated by the flame from a large gas blow-pipe, which played on the work until the brazing metal (sometimes called the brazing spelter) flowed completely through the joint and from end to end of the crack. From time to time,in order to assist the flow of the spelter, some dry borax was thrown on to it.

Care was necessary throughout the brazing operation not to overheat or burn the brass plate, and to ensure that the plate laid perfeetly flat all the time and with the sides in correct alignment. After brazing, it. was allowed to cool slowly, and, when cool, the surplus metal was filed away.

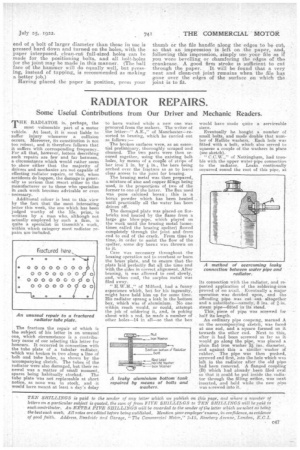

of Milford, had a funny experience which, hut for his ingenuity, might have held him up for some time. Hisradiator sprang a leak in the bottom box, which was of aluminium. No one within reach would, or could, attempt the job of soldering it, and, in poking aboutwith a rod, he made a number of other holes-14 in ail—so that the box

would have made quite a serviceable sieve.

Eventually he bought a number of small bolts, and made double that number of Halite washers. Each hole was fitted with a bolt, which also served to squeeze a couple of the washers in place (see sketch).

• " C.C.W.," of Nottingham, had trouble with the upper water-pipe connection to the radiator. Leaks continually occurred round the root of this pipe, at

its connection with the radiator, and repeated application of the soldering-iron proved of no avail. Eventually a major operation was decided upon, and the offending pipe was cut out altogether and a substitute—namely, 8 ins, of a-in. steam pipe—fitted in its stead.

This, piece of pipe was screwed for half its. length.

An ordinary pipe coupling, marked A on the accompanying sketch, was faced at one end, and a. square formed on it towards the other end. Next to this, after it had been screwed as far as it would go along the pipe, was placed a plain flat iron washer 2i ins, diameter, and against this a similar washer of rubber. The pipe was then pushed, screwed end first, Into the hole which was left in the radiator after the old pipe had been removed. A flanged coupling (B) which had already been filed oval so that it could be put inside the radiator through the filling orifice, was next -inserted, and held while the new nipe was screwed into it.