A LIVELY BEAST

Page 40

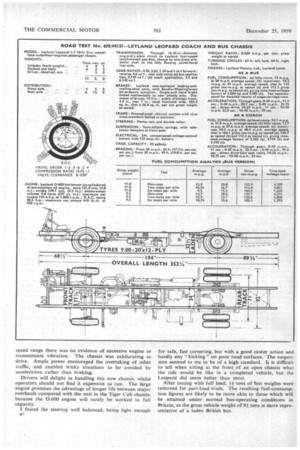

Page 41

Page 42

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

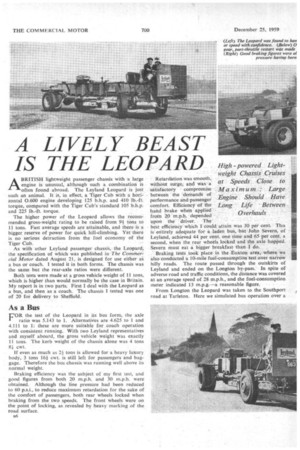

IS THE LEOPARD High powered Light ABRITISH lightweight passenger chassis with a large engine is unusual; although such a combination is often found abroad. The Leyland Leopard is just such an animal. It is, in effect, a Tiger Cub with• a horizontal 0.600 engine developing 125 b.h.p. and 410 lb.-ft. torque, compared with the Tiger Cub's standard 105 b.h.p.

and 225 lb.-ft. torque. .

The higher power of the Leopard allows the recommended gross-weight rating to be raised from 91 tons to 11 tons. Fast average speeds are attainable, and there is a bigger reserve of power for quick hill-climbing. Yet there is no serious detraction from the fuel economy of the Tiger Cub.

As with other Leyland passenger chassis, • the Leopard; the specification of which was published in The Commer dal Motor dated August 21, is designed for use either as a bus or coach. I tested it in both forms. The chassis was the same but the rear-axle ratios were different.

Both tests were made at a gross vehicle weight of 11 tons, which is higher than would normally be the case in Britain. My report is in two parts. First I deal with the Leopard as a bus, and then as a coach. The chassis I tested was one of 20 for delivery to Sheffield.

As A Bus

.pOR the test of the Leopard in its bus form, the axle ratio was 5.143 to 1. Alternatives are 4.625 to 1 and 4.111 to 1: these are more suitable for coach operation with consistent running. With two Leyland representatives and myself aboard, the gross vehicle weight was exactly 11 tons. The kerb weight of the chassis alone was 4 tons cwt.

If even as much as 21 tons is allowed for a heavy luxury body, 3 tons 161 cwt. is still left for passengers and baggage. Therefore the bus chassis was running well above its normal weight.

Braking efficiency was the subject of my first test, and good figures from both 20 m.p.h. and 30 m.p.h. were obtained. Although the line pressure had been reduced to 60 p.s.i., to reduce maximum retardation for the sake of the comfort of passengers, both rear wheels locked when braking from the two speeds. The front wheels were on the point of locking, as revealed by heavy marking of the road surface.

r36 Retardation was smooth,

without surge, and was ' a at Speeds Close to satisfactory compromise maximum Large between the 'demands of performance anti passenger _Engine . Should Have comfort Efficiency of the LongLife Between

hand brake when applied from 20 'm.p.h. depended upon the driver. The best efficiencywhich I could attain was 30 per cent. This is entirely adequate for a laden bus, but John Severn, of Leyland, achieved 44 per cent. one time and 65 per cent, a second, when the rear wheels locked and the axle hopped. Severn must eat a bigger breakfast than I do.

Braking tests took place in the Euxton area, where 'we also conducted a 10-mile fuel-consumption test over narrow hilly roads. The route passed through the outskirts of Leyland and ended on the Longton by-pass. In spite of adverse road and traffic conditions, the distance was covered at an average speed of 28 m.p.h., and the fuel-consumption meter indicated 13 m.p.g.---a reasonable figure.

From Longton the Leopard was taken to the Southport road at Tarleton. Here we simulated bus operation over a

Overhauls

5.9-mile course. First we ran non-stop, then made two stops every mile, and finally six stops per mile. Each stop was for 15 seconds and the engine was left idling. Fuelconsumption rates obtained are detailed in an accompanying data panel. They show praiseworthy economy under stage-carriage conditions.

During the run when six stops were made per • mile, the average efficiency of brake applications was about 20 per cent., except that the last stop was a "crash." This was done to find out if any fade had occurred. The Tapley meter showed that the brakes had lost none of their efficiency. The Leyland driver accelerated from 0-20 m.p.h. in some 17 seconds during this fuel-consumption trial, and acceleration times were later assessed in their own right. It was found that better results could be attained up to 40 m.p.h. by starting in bottom gear instead of using second. Four seconds were saved over the time required to reach 40 m.p.h. from rest when bottom gear was employed compared with starting in second. Good direct-drive times were recorded and the engine and transmission behaved smoothly.

Parbold Hill, which• has an average gradient of 1 in 12, was the scene of hillclimb and brake-fade tests. The ascent of three-quarters of a mile occupied only 3 minutes 3& seconds—a fast climb for a bus of 11 tons gross. Second was the lowest ratio employed, and was engaged for a total of 2 minutes 8 seconds, during which the minimum speed was. 12 m.p.h.

Slight exhaust smoke could be seen when the engine was running near its governed speed during the ascent. Temperature of the water in the cylinder head rose from 170-175 degrees F. This is negligible and indicated ample cooling capacity for all occasions.

The effectiveness of the brakes was halved by a descent in neutral at 20 m.p.h., the foot brake being used to keep the speed down to this figure. This was not because, of fade, in the normal sense. The reduction was caused by a drop in line pressure to 35 p.s.i. I found it impossible to keep my foot still on the pedal and inadvertently applied and released the brakes continually, so exhausting • the reservoir faster than the compressor could recharge it at engine-idling speed.

This often happens when an open chassis is being tested, and is chiefly caused by flexing. Had there been a body, there would have been greater chassis rigidity and it would have been easier to maintain a constant pedal application.

I took the Leopard back to the steepest part of the hill, where the gradient is reputed to be 1 in 6, and here the hand brake held the chassis quite easily. A start in second gear failed because of clutch slip, but an easy start in bottom gear was made at quarter throttle. A second-gear start was successfully made on a 1-in-10 section.

The Leopard was then driven on to the Preston by-pass for trial under motorway conditions, and the 1-7-mile circuit was completed at an average speed of 44 m.p.h. and a fuel-consumption rate of 10.3 m.p.g. The average speed is significant as it is within 12 per cent. of the vehicle's maximum speed of 50 m.p.h..

This emphasizes one of the chief advantages of a large engine: the gap between average and maximum speeds is small. The Preston by-pass is not noted for its favourable grading, but the lowest speed anywhere on it was 30 m.p.h. This was on the gradient at the Broughton end. On Sannlesbury Hill the minimum speed was 37 m.p.h.

When given its head, the Leopard managed to reach 57 m.p.h. coming down Samlesbury Hill. Throughout the speed range there was no evidence of excessive engine or transmission vibration. The chassis was exhilarating to drive. Ample power encouraged the overtaking of other traffic, and enabled tricky situations to be avoided by acceleration rather than braking.

Drivers will delight in handling this new chassis, whilst operators should not find it expensive to run. The large engine promises the advantage of longer life between major overhauls compared with the unit in the Tiger Cub chassis, because the 0.600 engine will rarely heworked to full capacity.

I found the steering well balanced, being light enough for safe, fast cornering, but with a good castor action-and hardly any " kicking " on poor road surfaces. The suspension seemed to me to be of a high standard. It is difficult to tell when sitting at the front of an open chassis what the ride would be like in a completed vehicle, but the Leopard did seem better than most.

After testing with full load, 11 tons of test weights were removed for part-load trials. The resulting fuel-consumption figures are likely to be more akin to those which will be attained under normal bus-operating conditions in Britain. as the gross vehicle weight of 9+ tons is more representative of a laden British bus. Acceleration was understandably improved. Times required to reach 20,30 and 40 m.p.h. from rest were 10 seconds, 19 seconds and 32.5 seconds respectively. In direct drive these three speeds were reached from 10 m.p.h. in 9 seconds, 20 seconds and 32.5 seconds respectively;

As a Coach

THE Leyland single-speed spiral-bevel axle was replaced

by an Eaton 18800 two-speed unit for the coaching tests, and the final-drive ratios were the highest available4.5 and. 6.142 to 1. Performance figures were taken over the same roads as for the chassis in bus form, and the EuxtonLongton course, which is 10 miles long, was covered at almost the same average speed.

More traffic hold-ups were encountered this time, but the fuel-consumption rate was better, being 13.7 m.p.g. An improvement in the fuel-consumption rate was also obtained on the Tarleton circuit. This was covered at an average speed of 31.8 m.p.h. and an average fuel-consumption rate of 15.1 m.p,g., representing a gain of 1.2 m.p.g.

Direct-drive acceleration was little different from that with the Leyland rear axle. The time taken to reach 20 m.p.h. from rest was slightly reduced, but the times for

0-30 m.p.h. and 0-40 m.p.h. were noticeably longer. Maximum, speeds in third and fourth gears with high and low ratios of the Eaton axle were as follows: third-low, 24 m.p.h.; third-high, 33 m.p.h.; fourth-low, 39 m.p.h.; fourth-high, 55 m.p.h.

The motorway trial showed an appreciably higher average speed-48.5 m.p.h. This is again commendably close to the maximum. Despite the higher average speed, compared with the bus version, the fuel-consumption rate was only 0.1 m.p.g. poorer.

Minimum speed on the Sarniesbury gradient was 39 m.p.h., and the rise was breasted in fourth-high, whilst the maximum speed on over-run was 60 m.p.h. The two-speed axle notably improved the hill-climbing performance, Parbold Hill being scaled in 3 minutes 11 seconds, 27 seconds faster than with the chassis in bus form. Secondhigh was the lowest ratio employed, and the engine pulled remarkably well when driving through this combination.

I think that the 4.111-to-1 single-speed axle would be better for most fast coaching operations. This unit would give a good maximdm speed of at least 60 m.p.h. and ample ability to climb gradients. It should also afford satisfactory acceleration and acceptable fuel economy.