Drawing the curtains

Page 20

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

Transport companies wanting new signwritten curtains from Norfolk manufacturer Structureflex are not always entirely precise in expressing their requirements. "Here it is on the back of a fag packet, now get on with it" is a common brief,

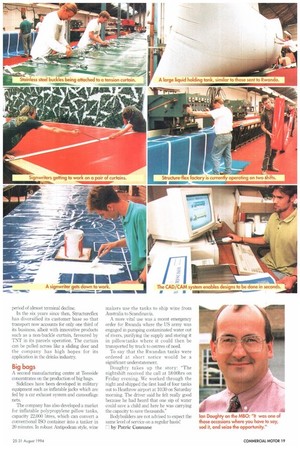

Fortunately, technology has enabled the Holtbased firm to establish a more accurate idea of what the haulier wants before committing paint to PVC. Computer aided design (CAD) means that a colour proof to scale of the new design can translate the customer's fag-packet doodles into something recognisable by both parties.

Graphics are drawn in the correct proportion on the CAD system and the machine can switch lettering from English to another language—Structureflex is busy producing its first curtains in Arabic. A client's logo or letterheading can be scanned in to create perfectly reproduced stencils cut straight from the computer on an adjoining cutting machine.

Aggravation

Structureflex managing director Ian Doughty has a simple attitude to the customer. "Our job is to take the aggravation off his desk and put it on ours."

That aggravation can include having to replace a curtain at short notice if one is ripped in an accident. A four-day turnround is possible.

The impossible is also routinely expected: "People ring up and say, you are delivering today, aren't you? And it turns out they haven't actually placed an order yet."

Because of the need to respond at short notice, the Norfolk factory holds a lot of fabric in stock—up to £180,000 worth of coated PVC at any one time. It is all supplied from Belgium. "No one in the UK can supply coated PVC in the three metre widths we require," explains production manager Steve Knight.

The quality of UK coating is poor and the cost phenomenal."

The factory works a two-shift system07.30hrs to 16,00hrs and 16.00hrs to 02.00hrs. There are 40 production workers—five have just been taken on to meet increased demand. No recognised trade union exists but procedures have been adopted to give the workers a level of input. This includes a safety committee and a negotiating team of two production workers which annually meet management to discuss terms and conditions.

Action teams are being set up to examine specific production issues such as welding, cutting, signwriting and finishing. The goal is to allow one hour per man per week training for each of these teams—a training budget has been established to meet this demand.

Large fleet customers such as Courage require a service that coincides with their maintenance schedule so that curtains can be replaced while the unit is undergoing service, thus avoiding two sets of delays. For this reason Structureflex keeps a database with specifications for the whole fleet, matching curtains to specific vehicles.

The company is a child of the seventies. It began life making re-usable big bags for shipping dry ingredients out to oil rigs. Around this time the management met Gerald Broadbent of Boalloy, and was asked to produce curtains for his trailer making operation.

By the time Doughty joined the business in 1988 the wind had gone from its sails with losses steadily mounting. An output of 120 curtains a week was producing marginal profit. The signwriting was on the wall. "We were determined not to lose it to competitors because with the business running at over capacity it could easily have been taken over and shut down," recalls Doughty Against this unpromising background, Doughty led a management buyout bid, raising £1m from venture capitalists 3i. "It was", he agrees, "an extremely high-risk enterprise. My house was on the line. But it was one of those occasions where you have to say, sod it, and seize the opportunity" Being boss wasn't an entirely foreign experience to Doughty he was managing director before the MBO—and he recognised changes were vital if the company was to survive. For one thing it had to lessen its dependency on the ailing transport industry where truck sales were about to enter a period of almost terminal decline.

In the six years since then. Structureflex has diversified its customer base so that transport now accounts for only one third of its business, albeit with innovative products such as a non-buckle curtain, favoured by TNT in its parcels operation. The curtain can be pulled across like a sliding door and the company has high hopes for its application in the drinks industry.

Big bags

A second manufacturing centre at Teesside concentrates on the production of big bags.

Sidelines have been developed in military equipment such as inflatable jacks which are fed by a car exhaust system and camouflage nets.

The company has also developed a market for inflatable polypropylene pillow tanks, capacity 22,000 litres, which can convert a conventional ISO container into a tanker in 20 minutes. In robust Antipodean style, wine makers use the tanks to ship wine from Australia to Scandinavia.

A more vital use was a recent emergency order for Rwanda where the US army was engaged in pumping contaminated water out of rivers, purifying the supply and storing it in pillowtanks where it could then be transported by truck to centres of need.

To say that the Rwandan tanks were ordered at short notice would be a significant understatement.

Doughty takes up the story: "The nightshift received the call at 18:001irs on Friday evening. We worked through the night and shipped the first load of four tanks out to Heathrow airport at 10:30 on Saturday morning. The driver said he felt really good because he had heard that one sip of water could save a child and here he was carrying the capacity to save thousands."

Bodybuilders are not advised to expect the same level of service on a regular basis!

El by Patric Cunnane