A.E.C. Trolleybuses Gain New Ground in Canada

Page 47

If you've noticed an error in this article please click here to report it so we can fix it.

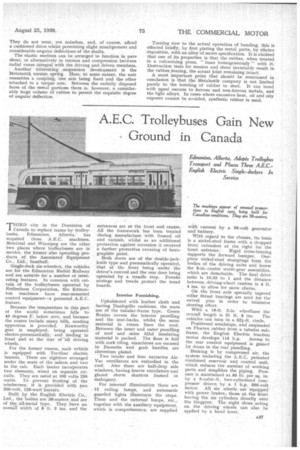

THIRD city in the Dominion of 1 Canada to replace trams by trolleybuses, Edmonton, Alberta: has acquired three A.E.C. machines. Montreal and Winnipeg are the other two places where trolleybuses are in service, the former also operating products of the Associated Equipment Co., Ltd., Southall.

Single-deck six-wheelers, the vehicles are for the Edmonton Radial Railway and are notable for a number of interesting features. In common with certain of the trolleybuses operated by Rotherham Corporation, the Edmonton machines have rear-mounted control equipment—a patented A.E.C. feature.

Because the temperature in this part of the world sometimes falls to 40 degrees F, below zero, and because the routes include many hills, sanding apparatus is provided. Kenworthy gear is employed, being operated electro-pneumatically, and feeding in front and at the rear of all driving wheels.

For the former reason, each vehicle is equipped with Torribar electric heaters. There are eighteen arranged under the seats of the saloon and two in the cab. Each heater incorporates two elements, wired on separate circuits. They are rated at 100 volts 250 watts, To prevent frosting of the windscreeu, it is provided with two 200-volt, 125-watt heaters.

Built by the English Electric Co., Ltd., the bodies are 38-seaters and are of the all-metal type. They have an overall width of 8 ft. 3 ins, and the entrances are at the front and centre. All the framework has been treated during manufacture with linseed oil and varnish, whilst as an additional protection against corrosion it received a further protective covering of ferrographite paint.

Both doors are of the double-jackknife type and pneumatically operated, that at the front being under the driver's control and the rear door being operated by a treadle step. Ferodo nosings and treads protect the tread boards.

Interior Furnishing.

Upholstered with leather cloth and having Dunlopillo cushions; the seats are of the tubular-frame type. Green Rexine covers the interior panelling and the seat-backs, whilst the same

• material in cream lines the roof. Between the inner and outer panelling of roof and sides Alfol insulating material is packed. The floor is laid with cork tiling, stanchions are encased in Doverite and grab handles are chromium plated.

Two intake and four extractor AirVac ventilators are embodied in the roof. Also there are half-drop side windows, having louvre ventilators and glazed storm shutters framed in mahogany.

For internal illumination there are • 12 ceiling lamps, and automatic guarded lights illuminate the steps. These and the external lamps, etc., together with the auxiliary equipment, which is comprehensive, are supplied with current by a 30-volt generator and battery.

With regard to the chassis, its basis is a nickel-steel frame with a dropped front extension at the right for the front entrance. Rigid cross-bracing supports the forward bumper. Onepiece nickel-steel stampings form the bodies of the driving axles and house the 8-in.-centre worm-gear assemblies, which are detachable. The final drive ratio is 10.33 to 1 and the distance between, driving-wheel centres is 4 ft. 4 ins, to allow for snow, chains, On the front axle specially tapered roller thrust bearings are used for the swivel pins in order to minimize steering effort.

With a 16-ft. 2-in, wheelbase the overall length is 31 ft. 8 ins. The vehicles can turn in a 62i-ft. circle. Positioned amidships, and suspended on Floatex rubber from a tubular subframe, the English Electric traction motor develops 115 h.p. Access to the rear control equipment is gained by doors in the rear panelling, Braking is by compressed air, the system including the A.E.C. patented combined reservoir and control unit, which reduces the number of working parts and simplifies the piping. Pressure is maintained at 85 lb, per sq. in. by a 5-cubic-ft. two-cylindered compressor driven by a 1 hp. 500-volt motor. All six wheels are equipped with power brakes, those at the front having the air cylinders directly over the kingpins. The eight shoes acting on the driving wheels can also be applied by a hand lever.