TESTING TYRES

Page 76

If you've noticed an error in this article please click here to report it so we can fix it.

for

BALANCE

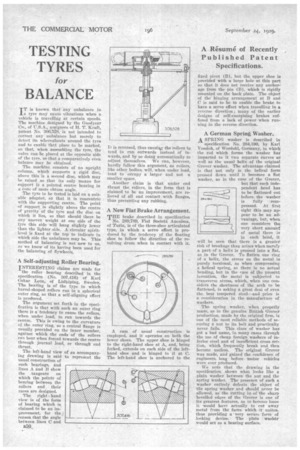

IT is known that any unbalance in a tyre may cause vibrations when a vehicle is travellitig at certain speeds. The machine designed by the Goodyear Co., of U.S.A., assignees of H. T. Kraft, patent No. 306,528, is not intended to correct any unbalance but merely to detect its whereabouts around the tyre and to enable that place to be marked, so that, when assembling the tyre, the valve can. be placed at the opposite side of the tyre, so that a comparatively even balance may be obtained.

The machine consists of an upright column, which supports a rigid disc, above this is a second disc, which may be raised so that its only means for miPport is a pointed centre bearing in a cone of more obtuse angle. The tyre to be tested is laid on a suitable adapter, se that it is concentric with the supporting centre. The point of support is slightly above the centre of gravity of the tyre and the disc on which it lies, so that should there be any uneven weight at one side of the tyre this side will hang slightly lower than the lighter side. A circular spiritlevel is fixed at the top to indicate in which side the unbalance may be. This method of balancing is not new to us, US we know of its having been used for the balancing of flywheels.

A Self-adjusting Roller Bearing.

INTERESTING claims are made for the roller bearing described in the specification (No. 307,416) of Karl Oskar Leon, of Lidkoping, Sweden. The bearing is of the type in which barrel-shaped rollers run in a spherical outer ring, so that a self-aligning effect is produced.

The argument set forth in the specification is that with such an outer ring there is a tendency to cause the rollers, when under load, to run towards the centre. This is owing to the curvature of the outer ring, so a central flange is usually provided on the inner member, against which the ends of the rollers can bear when forced towards the centre through journal load, or through end thrust.

The left-hand view of an accompanying drawing is said to represent the usual construction of such bearings, and lines A and B show the .tangents on which the points of bearing between the rollers and their races are designed.

The right-hand view is of the form of bearing which is claimed to be an improvement, for the , reason that the angle e between lines C and is reversed, thus causiv the rollers to tend to run outwards instead of inwards, and by so doing automatically to adjust themselves. We can, however, hardly follow this argument, as rollers, like other bodies, will, when under load, tend to occupy a larger and not a smaller space.

Another claim is that under end thrust the rollers, in the form that is claimed to be an improvement, are relieved of all end contact with flanges, thus preventing any rubbing.

A New Fiat Brake Arrangement.

THE brake described in specification

No. 289,789, Fiat Societa Anonima, of Turin, is of the three-shoe articulated type, in which a servo effect is produced by the tendency of the floating shoe to follow the direction of the revolving drum when in contact with it.

fixed pivot (B), but the, upper shoe is provided with a large hole at this part so that it does not receive any anchorage from the pin (B), which is rigidly mounted on the back plate. The object of the hinging arrangement at B and C is said to be to enable the brake to have a servo effect when travelling in a reverse direction ; many of the earlier designs of self-energizing brakes suffered from a lack of power when running in the reverse direction.

A German Spring Washer.

A SPRING washer is described in specification No. 284,190, by Karl Vossloh, of Werdohl, Germany, in which the rod which forms the washer has imparted to it two separate curves as well as the usual helix of the original Grover washer. The advantage claimed is that not only is the helical form pressed down until it becomes a flat washer, as in the case of the Grover, but that each independent bend has to be flattened out before the washer is fully compressed. At first sight this may appear to he an advantage, but, when one considers the! very short amount of metal there is in each bend, it will be seen that there is a greater risk of breakage than arises when merefy • a part of a helix is pressed into a flat, as in the Grover. To flatten one ring of a helix, the stress on the metal is purely torsional, as when compressing a helical spring, so there is no actual bending, but in the ease of the present invention, the metal is subjected to transverse stress, which, when one considers the shortness of the arch to be flattened, is asking a great deal of even the best tempered steel—and price is a consideration in the manufacture of washers.

The spring washer, when properly made, as in the genuine British Grover production, made by the original firm, is one of the most reliable methods of securing a nut to its bolt and practically never fails. This class of washer has got a bad name, in many cases through the use of cheap foreign washers of inferior steel and of insufficient cross section, which frequently break and then become useless. The original Grover was made, and gained the confidence of engineers, long before motor vehicles were ever produced.

We note that the drawino•' in the specification shows what looks like a plain washer between the nut and the spring washer. The presence of such a washer entirely defeats the object of the spring washer and should never be allowed, as the cutting in of 'the sharp bevelled edges of the Grover is one of its greatest features, as to become loose it would have actually to cut away metal from the faces whiCh -it unites, thus providing a very seCure lona of locking device. The plain washer would act as a bearing surface.