-A NEW CHASSIS

Page 62

Page 63

If you've noticed an error in this article please click here to report it so we can fix it.

for

Double-deck Buses

Details of a New 50-Passenger Crossley Vehicle, Which is a Development of the Six-cylinder Model Recently Described Ex clusively in This Journal.

WE are able this week to give preliminary particulars of another chassis made by Crossley Motors, Ltd., Gorton, Manchester, which is new in the sense that it is capable of carrying double-deck coachwork. It is the logical development of the recently introduced sixcylinder model described exclusively in a recent issue of The Commercial Motor. The engine, for example, is exactly the same, likewise many of the main components, but the new machine incorporates a new frame to enable it to carry the additional load imposed by an extra saloon deck.

The wheelbase is the same as that of the chassis already described, i.e., 10 ft. 7 ins., but the track is slightly different, the front wheels having a tread of 6 ft. 21 ins, and those at the rear 5 ft. 101 ins. Although the frame bears a marked resemblance to the earlier model, it is of entirely new design and incorporates side-members which are 11 ins, deep instead of 9 ins, as on the earlier type, whilst the overall length of the chassis now comes within the 25-ft. limit. The laden _height of the frame, too, is rather lower than the single-deck type, being 1 ft. 10 ins, at any point between the axles. The turning circles are (right) 59 ft. 2 ins., and (left) 57 ft. 5 ins.

We can now turn to a consideration of the engine, transmission:etc. With a capacity of 6,796 c.c., the power unit is capable of producing 52 b.h.p. at 1,000 r.p.m. and 110 b.h.p. at maximum revolutions. The unit is built on straightforward lines, side-by-side valves being dispcsed along the near-side of the monobloc cylinder casting, and, being

cperate.d by adjustable tappets of the roller type, should run for long periods without requiring attention. In the interests of rigidity and smooth running, a massive crankshaft is held in seven bearings, all of which are fed with oil under pressure from a dry-sump systemYr A single-plate clutch transmits the d rive through a four-forward-speed gearbox to an offset under-drivenworm rear axle, through the medium of an open propeller shaft having three metal universal joints. The forward part of the shaft is supported at its rear by a large selfaligning ball bearing. The ratios of the gearbox, combined with the

reduction gearing for the rear axle, are the same as in the original sixcylinder passenger chassis. These are: 1st, 38.24 to 1; 2nd, 21.38 to 1; 3rd, 12.22 to 1, and top 6.5 to 1. The rear axle is considerably offset in order to Provide a low floor level for botlisaloons.

The bodywork next claims attention. As will be seen from the illustrations, it is clear that care has been taken to achieve a bold but

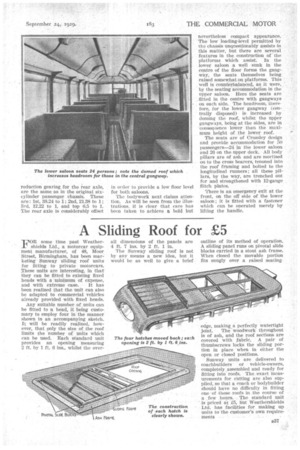

nevertheless compact appearance. The low loading-level permitted by the chassis unquestionably assists in this matter, but there are several features in the construction of the platforms which assist. In the lower saloon a well sunk in the centre of the floor forms the gangway, the seats themselves being raised somewhat on platforms. This well is counterbalanced, as it were, by the seating accommodation in the upper saloon. Here the seats are fitted in the centre with gangways on each side. The headroom, therefore, for the lower gangway (centrally disposed) is increased by doming the roof, whilst the upper gangways, being at the sides, are in • consequence lower than the inakimum height of the lower roof.

The seats are of Crossley design and provide accommodation for 150 passengers-24 in the lower saloon and 26 on the upper deck. All body pillars are of ash and are mortised on to the cross bearers, tenoned into the roof framing and bolted to the longitudinal runners; all these pillars, by the way, are trenched out for and strengthened with 12-gauge flitch plates.

There is an emergency exit at the front, on the off side of the lower saloon ; it is fitted with a fastener which can be operated merely by lifting the handle.