How the Dennis Motor Fire-pump Works.

Page 14

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

A party of fire-brigade officers and Press representatives visited \Veybridge, last week, on the invitation of Dennis Brothers, Limited, in order to witness the working of the company's patent turbine fire-engine. The exterior and general lines of the machine were illustrated by us on the 23rd July, but we had not then had the advantage of an opportunity for personal inspection under practical loads and conditions. The tests in question, as well as a close examination of the whole outfit, now enable us to revert to the machine and its performances at some length.

With ten people up, and a gross weight of some 4 tons, it travelled from London down to Weybridge, a distance of about 20i miles, in little more than an hour, and during the run the drivers of some ten Dennis landaulets and one Dennis char-à-bancs had their work Cut out to overtake it : the passengers in the two cars which happened to catch up the fire-engine at the foot of Kingston Hill will certainly be ready to testify to its speed up gradients, and its handiness in traffic—dense at times—was apparent to all observers. Arrived at the scene of the demonstration, one found the local firemen and residents all agog, while the competitive " steamer " very soon began to blow off pressure at its safety valve in a manner, and with a frequency, which showed that the men in charge meant to do their best.

Test No. I was left to Dennis only, because the older engine was not equipped to be fed from the town's mains. Our first illustration shows the reception of supply from four standard hose ; shortly after the photograph was taken, the aluminium body of the casting for the quadruple attachment cracked without any warning, the violent discharge of water giving an unappreciated "ducking " to not a few of the spectators, and to Mr. Down ing more than all. We then learnt, to our no small surprise, that the mains were carrying a pressure of no lb. on the square inch, but everybody will agree that this was abnormal, for 50 lb. is nearer to the average. Messrs. John and Raymond Dennis were exceedingly sorry that the pressure had not been regulated to a low intensity on the suction side, as the conditions which were put upon them resulted in but a very small increase of pressure, and therefore of velocity, during the passage of the water in this test from the suction to the delivery side of the turbine. The convenient and positive manner in which water can

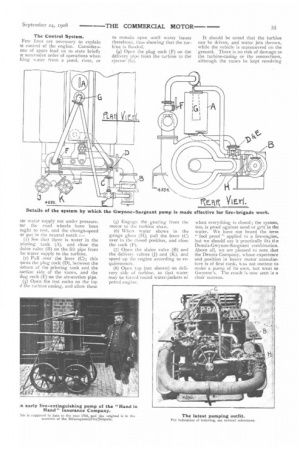

be taken in from any hydrants and a town main, its pressure augmented to about 1201b. on the square inch by the Gwvnne-Sargeant pump on the Dennis engine, and the four streams of feed combined into a single or more deliveries at correspondingly greater velocities of issue, cannot but be admitted on the most cursory study of the accompanying drawings, text, and views, several of which have been specially prepared by us.

Test No. 2 was in direct competition with a " steamer," and consisted of a series of comparative throws. Both engines sucked direct from the river, a lift of nearly to feet, and some confusion arose at the outset from the fact that the Dennis nozzle was laid against the side of the other engine. This gave the impression of a superior performance by the older type of engine, but the erroneous indication was corrected by a change of the discharges se that each was adjacent to its impelling force. Try as they Might, the three men who were looking after the " steamer." at no time equalled the results obtained by the two who stood by the petrol engine. We write" stood by "advisedly, for there was so much less to do. Vail. ous sizes of nozzles were tested, and soon the" steamer " ceased to compete; either the men in charge had lost heart, or there was not enough coal. Th( Dennis machine continued, subject tc a few minutes' delay between two ol the demonstrations : the priming tanli had been inadvertently allowed to empt3 itself, and water had to be put in by th( bucketful. With so many lines of hos( hard by, we wondered why it was not fined in as many seconds from the mair as it took minutes from the river. Th( last test of all was through 3oo feet o: hose, when two jets were thrown to E height of fully so feet.

The Control System.

Few lines are necessary to explain le control of the engine. Consideraons of space lead us to state briefly le successive order of operations when fling water from a pond, river, or

ler water supply not under pressure. ter the road wheels have been >ught to rest, and the change-speed .er put in the neutral notch :— (t) See that there is water in the ?riming tank (A), and close the duice valve (B) on the lift pipe from he water supply to the turbine.

(2) Pull over the lever (C); this >pens the plug cock (D), between the >ottom of the priming tank and the niction side of the vanes, and the )lug cock (E) on the air-suction pipe.

(3) Open the test cocks on the top 4 the turbine casing, and allow these to remain open until water issues therefrom, thus showing that the turbine is flooded.

(4) Open the plug cock (F) on the delivery pipe from the turbine to the ejector (G).

(5) Engage the gearing from the motor to the turbine shaa.

(6) When water shows in the gauge glass (II), pull the lever (C) over to the closed position, and close the cock (F.). (7) Open the sluice valve (B) and the delivery valves (J) and (K), and speed up the engine according to requirements.

(8) Open tap (not shown) on delivery side of turbine, so that water may be forced round water-jackets of petrol engine.

It should be noted that the turbine can be driven, and water jets thrown, while the vehicle is manceuvred on the ground. There is no risk of damage to the turbine-casing or the connections, although the vanes be kept revolving when everything is closed; the system, too, is proof against sand or grit in the water. We have not heard the term " fool proof" applied to a fire-engine, but we should say it practically fits de Dennis-Gwynne-Sargeant combinatien. Above all, we are pleased to note that the Dennis Company, whose experience and position in heavy motor manufacture is of first rank, was not content to make a pump of its own, but went to tiwynne's. The result is now seen in a clear success.