The Brewers' Exhibition.

Page 13

Page 14

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

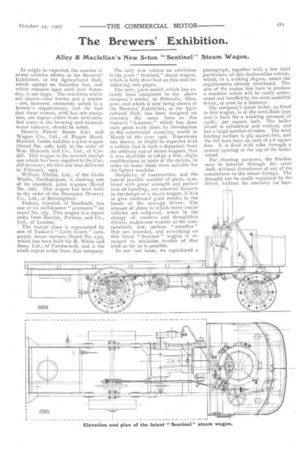

Alley & Maclellan's New 3-ton "Sentinel" Steam Wagon.

As might be expected, the number of motor vehicles shown at the Brewers' Exhibition, at the Agricultural Hall, which opened on Saturday last, and which remains open until next Saturday, is not large. The machines which are shown—four lorries and a tractor —are, however, eminently suited to a brewer's requirements, and the fact that these motors, with but one exception, are repeat orders from well-satisfied users in the brewing and mineralwater industry, should be noted.

Mann's Patent Steam Cart and Wagon Co., Ltd., of Pepper Road, Hunslet, Leeds, exhibits a 5-ton wagon (Stand No. 108), built to the order of Wm. Hancock and Co., Ltd., of Cardiff. This wagon is the seventh similar one which has been supplied to the Cardiff brewery ; the first one was delivered in February, 1903.

William Allchin, Ltd., of the Globe Works, Northampton, is showing one of its standard, 5-ton wagons (Stand No. x66). This wagon has been built to the order of the Brampton Brewery Co., Ltd., of Birmingham.

Fodens, Limited, of Sandbach, has one of its well-known " 5-tonners " on stand No. 173. This wagon is a repeat order from Barclay, Perkins, and Co., Ltd., of London.

The tractor class is represented by one of Tasker's " Little Giant," compound, steam tractors (Stand No. 130), which has been built for R. White and Sons, Ltd., of Camberwell, and is the ninth repeat order from that company. The only new vehicle on exhibition is the 3-ton " Sentinel," steam wagon, which is fully described on this and the following two pages.

The new, 3-ton Model, which has recently been completed in the above company's works, at Poltnadie, Glasgow, and which is now being shown at the Brewers' Exhibition, at the Agricultural Hall, has been designed on precisely the same lines as this maker's "6-former," which has done such good work since its introduction to the commercial motoring world in March of the year 1906. Experience has shown, as might be expected with a vehicle that is such a departure from the ordinary run of steamwagons, that it was desirable to adopt a few, slight modifications in some of the details, in order to make them more suitable for the lighter machine.

Simplicity of construction, and the lowest possible number of parts, combined with great strength and perfect ease of handling, are essential features in the design of a steam wagon, if it is to give continued good results in the hands of the average driver. The amount of abuse to which many motor vehicles are subjected, when in the charge of careless and thoughtless drivers, makes one wonder at the comparatively few, serious " smashes " that are recorded, and everything on this latest " Sentinel " wagon is arranged to minimise trouble of that kind as far as is possible. In our last issue, we reproduced a photograph, together with a few brief particulars, of this businesslike vehicle, which, in a striking degree, meets the requirements already mentioned. The aim of the maker has been to produce a machine which will be easily understood and handled by the most unskilful driver, or even by a labourer. The company's latest boiler, as fitted to this wagon, is of the semi-flash type and is built for a working pressure of 23o1b., per square inch. The boiler vessel is cylindrical and vertical, and has a large number of tubes. The total heating surface is 361 square feet, and the fire bars have an area of 2.6 square feet. It is fired with coke through a central opening at the top of the boiler vessel.

For cleaning purposes, the fire-box may be lowered through the outer shell, without disturbance of any of the connections to the steam fittings. The draught can be easily regulated by the driver, without the necessity for leav

ing his seat, and the fire-grate, which is in two sections, with each half suspended on trunnions, may easily be tilted for cleaning. In the uptake of the boiler, a solid-drawn, steel superheater-tube is fitted, and the surface of this tube is sufficient to ensure that the steam is superheated to about Iso degrees Fahrenheit over and above the temperature of saturated steam.

The various boiler fittings are all of heavy make, and are packed with asbestos. As an auxiliary to the engine_ pump, which we show by a sectional drawing on page 18o, a " Gresham," patent injector is fitted. Both the feedwater check-valves are arranged within the same fitting, and a stop valve is arranged between them and the boiler, so that one or both of the valves may be taken out for examination, or re-grinding, while the boiler is under steam.

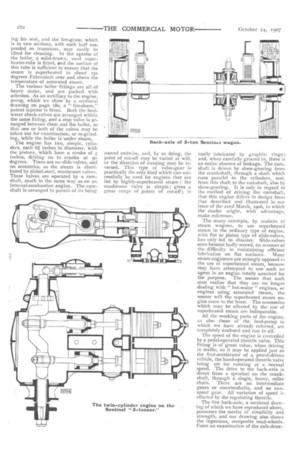

The engine has two, simple, cylinders, each 6i inches in diameter, with the pistons, which have a stroke of 5 inches, driving on to cranks at 90 degrees. There are no slide valves, and no eccentrics, as the steam is distributed by nickel-steel, mushroom valves. These valves are operated by a camshaft, much in the same way as on an internal-combustion engine-. The camshaft is arranged to permit of its being moved endwise, and, by so doing, the point of cut-off may be varied at will, or the direction of running may be reversed. This type of valve-gear is practically the only kind which can successfully be used for engines that are fed by highly-superheated steam : the mushroom valve is simple; gives a great range of points of cut-off ; is

easily lubricated by graphite rings; and, when carefully ground in, there is an entire absence of leakage. The cam., shaft is driven by skew-gearing from the crankshaft, through a shaft which runs parallel to the cylinders, and, from this shaft to the camshaft, also by skew-gearing. It is only in regard to the method of driving the camshaft, that this engine differs in design from that described and illustrated in our issue of the 22nd March, 1906, to which the reader might, with advantage, make reference.

The many attempts, by makers of steam wagons, to use superheated steam in the ordinary type of engine, with flat or piston type of slide-valves, has only led to disaster. Slide-valves soon become badly scored, on account of the difficulty in maintaining efficient lubrication on flat surfaces. Many steam engineers are strongly opposed to the use of superheated steam, because they have attempted to use such an agent in an engine totally unsuited for the purpose. The sooner that such men realise that they are no longer dealing with " hot-water " engines, or engines using saturated steam, the sooner will the superheated steam engine come to the front. The economies which may he effected by the use of superheated steam are indisputable.

All the working parts of the engine, as also those of the feed-pump to which we have already referred, are completely enclosed and run in oil.

The speed of the engine is controlled by a pedal-operated throttle valve. This fitting is of great value, when driving in traffic, as it may be applied just as the foot-accelerator of a petrol-driven vehicle, the hand-operated throttle valve being set for running at a normal speed. The drive to the back-axle is direct from a sprocket on the crankshaft, through a single, heavy, roller chain. There are no intermediate gears or countershafts, and no twospeed gear. All variation of speed is effected by the regulating throttle.

The live back-axle, a sectional drawing of which we have reproduced above, possesses the merits of simplicity and strength, and our drawing also shows the ingenious, composite road-wheels. From an examination of the axle-draw log, it will be seen that the wheelcentre is of metal, and forms a large, male cone. Encircling this cone, but separated from it by wooden blocks, is the steel rim, or tire. As the wood shrinks, or as the tire stretches, the wheel may he tightened up by means of bolts and a flange, the wooden blocks being then forced higher up the cone, and thus more tightly gripping the tire, without the necessity for taking the wheel off its axle, and putting it in a wheel-press. It is claimed that these wheels give the same cushioning effect as wooden wheels, without the inherent weaknesses of the latter type.

The steering-gear of this model differs slightly from that of the " 6tonner." It is of the Ackermann type, and is both rapid and positive in its action.

The overall dimensions of this wagon are : length, 16 feet, 8 inches ; width, 6 feet ; height,.8 feet, 3 inches ; height of platform (loaded), 3 feet, 5 inches. The platform has 70 square feet of sur face available for goods ; the wheel-base' is 9 feet, 8 inches; and the wheel-gauge is 4 feet, 6 inches. It is stated to be capable of taking 3 tons on its own platform up a gradient of I in 7. Three cwt. of coke may be taken in the bunkers, and over too gallons of water may be carried in the tank at the hack of the wagon. The water tank is provided with a steam water-lifter, and 30 feet of suction-hose. The wagon shown has been built for Davenports, Ltd., of Bath Row, Birmingham.