The First Gas Filling Station

Page 36

If you've noticed an error in this article please click here to report it so we can fix it.

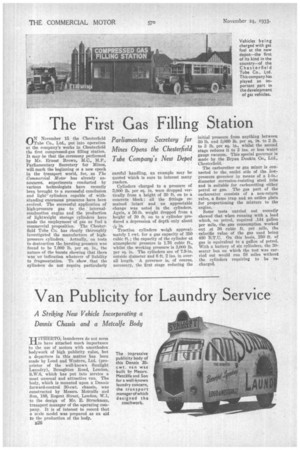

Parliamentary Secretary for Mines Opens the Chesterfield Tube Company's New Depot ON November 15 the Chesterfield Tube Co., Ltd., put into operation at the company's works in Chesterfield the first compressed-gas filling station. It may be that the ceremony performed by Mr. Ernest Brown, M.C., Parliamentary Secretary for Mines, will.mark the beginning al a new epoch in the transport world, for, as The Commercial Motor has already announced. experiments conducted by various technologists have recently been brought to a successful conclusion and lightcylinders capable of withstanding enormous pressures have been evolved. The successful application of high-pressure gas to the ' internalcombustion engine and the production of lightweight storage cylinders have made the employment' of gas as fuel a commercial preposition. The Chesterfield Tube Co. has clearly theroughly investigated the manufacture of highpressure cylinders. Actually, on tests to destruction the bursting pressure was found to be 7,000 lb. per sq. in., the nature of the bursts showing that there was no indication whatever of liability to fragmentation. To show, that the cylinders do not require particularly

careful handling, an example may be quoted which is sure to interest many readers.

Cylinders charged to a pressure of 8,000 lb. per sq. in, were dropped vertically from a height of 30 ft. on to a concrete block: all the fittings remained intact' and no appreciable change was noted in the cylinders. Again, a 56-lb. weight dropped from a height of 30 ft. on to a cylinder produced a depression of depth only about 71.4in. Traction cylinders weigh approximately 1 cwt. for a gas capacity of 350 cubic ft.; the capacity of the cylinder at atmospheric pressure is 1.76 cubic ft., whilst the working pressure is 3,000 lb. per sq. in. The cylinders are of 7.9-in. outside diameter and 6 ft. 2 ins. in overall length. A governor is, of course, necessary, the first stage reducing the

initial pressure from anything between 30 lb. and 3,000 lb. per sq. in. to 2 lb. to 3 lb. per sq. in., whilst the second stage reduces it to 3 ins, or less water gauge vacuum. This special governor is made by the Bryan Donkin Co., Ltd., Chesterfield.

The carburetter or gas mixer is connected to the, outlet side of the lowpressure governor by means of a 1-in.diameter corrosion-resisting steel tube and is suitable for carburetting either petrol or gas. The gas part of the carburetter consists of a non-return valve, a flame trap and an orifice plate for proportioning the mixture to the engine.

Some testa carried out recently showed that when running with a load which, on petrol, required .144 gallon per mile, the gas consumption worked out at 36 cubic ft. per mile' the calorific value of the gas used being 480 B.T.U. On this basis, _250 ft. of gas is equivalent to a gallon of petrol. With a battery of six cylinders, the 30seater bus on which the test was carried out would run 58 miles without the cylinders requiring to be recharged.