GULLY AND CESSPOOL EMPTYING.

Page 118

Page 119

Page 120

If you've noticed an error in this article please click here to report it so we can fix it.

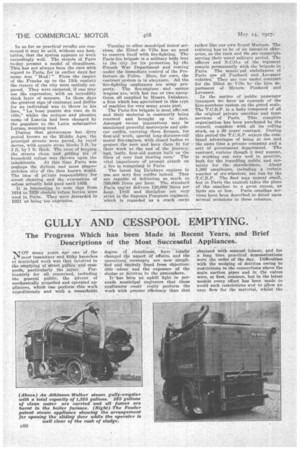

TOT many years ago one 'of themot4 insanitary and filthy braanches of municipal work was that involved in the emptying of Street 'gullies:and cess pools, particularly the latter. Fortanately for all concerned, including the general public, the advent of mechanically propelled and operated appliances, which can perform this work expeditiously and with a remarkable degree of cleanliness, have totally changed the aspect of affairs, and the operations necessary are now simplified and -entirely freed from objectionable odour and the exposure of the sludge or detritus to the atmosphere.

It-has been an uphill fight to persuade municipal engineers that these appliances could really perform the work with greater efficiency than that

obtained with manual labour, and for a long time practical demonstrations were the order of the day. Difficulties with the wedging of detritus owing to restrictions in the connections above the main suction pipes and in the valves were, at first, common, but in the latest models every effort has been made to avoid such restrictions and to allow an easy flow for the matuial, whilst the labour involved in lifting the comparatively heavy suction pipes has been greatly reduced by providing excellent balancing gear.

Gully and cesspool emptying apparatus can be supplied by the makers of quite a number of Petrol and steam chassis. In the case of the petrol type, separate pumps must be provided for exhausting the tanks, but with the steam wagon use is generally made of the steam itself, and steam can also be used to assist in blowing out the sludge while the vehicle is being emptied.

In the Atkinson-Walkeir gully emptier, the tank has a total content of 1,350 gallons, but a division plate iu the front isolates 350 gallons of clean water for both feeding and gully flush -lug. The vacuum is produced by a

simple steam air-ejector. The 5-in. armoured, flexible hose has a quickopening valve of full bore and the fumes are conveyed to the boiler furnace, where they are consumed. •

A slightly larger capacity is afforded by the Clayton gully emptier, this having a 1,400-gallon tank mounted on a 6-ton overtype wagon. In this case, the division ler the fresh water is so arranged that 1,000 gallons are retained. The steam-operated ejector enables the largest gully to be emptied without losing the vacuum, and this is easily and quickly maintained when travelling from one gully to another. This vehicle is also equipped with streetsprinkling gear, and when used for this purpose the two tanks are connected, thus givingthe full capacity for water:

Great successes have been obtained by the Dennis municipal machines of this class. The gully emptier is operated on the vacuum system, a rotary pump exhausting air through

the tank. The suction hose is suspended from a rotary jib, whilst for emptying a tipping angle of 40 degrees ía obtainable. This ensures that the sludge is rapidly deposited. An interesting feature from the health point of view is that the air withdrawn from the tank is burnt by the hot exhaust gases before escaping to the atmosphere. From 60-70 gullies of the pot type can be dealt with at each load, and they are all resealed with clean water.

Another Dennis machine combines street watering and washing with gully emptying, and was originally introduced to meet the needs of small towns, but it is also proving popular with the larger municipalities, Several of whom have these apPliances in use. The Dennis cesspool emptier also works on the vacuum principle: An

• advantage in the design is that in the event of the suction pipes not. being 'sufficiently tightened, the sewage is not spilt. By reversing the action of the pomp at the completion of the job, the suction pipes may be emptied ; any drainillgs therefrom are caught by special receptacles placed for that purpose on the vehicle and detachable for emptying. The pump can exert considerable pressure, and the load can be deposited at a level considerably above that at which the vehicle, is standing.

The latest type gully-emptying machine of Garrett make was recently delivered-to the Wandswerth Borough Council. This is interesting because besides being suitable . for ordinary emptying special provision has been

made for using the machine for cesspool work as and when required. In addition, it is capable of being employed for street-watering purposes, and nozzles are fitted at the front. A similar machine is in hand for the Dagenham Urban District Council.

A very excellent type of steam gully

emptier is the Fowler. It also is built for street watering and street washing. "The working vacuum is produced by the steam ejector. in less than half a minute, and there is a patented system for drawing surplus water from the sludge tank so that a greater effective capacity is afforded for the solid matter, thus necessitating fewer journeys to the tip. ...The self-emptying sludge tank has a slope of 30 degrees, and there is no need to crawl inside the tank to clean it out, whilst cleaning is .afsofacilitated by a highpressure water jet.The sludge tank holds 9::5 gallons, the upper vacuum tank an additional. 170 gallons 'and the clean-water tank. 080 gallons. For ease in handling, the 41 ins: diameter suction pineis Completely -balanced. . In our .centre-pages article is published an illuStration of alarge Halley petrol-driven gully emptier. This can also be employed for emptying cesspools awl bas. read-sprinkling equipment. The-ehassis employed is the six'eylindered model with overhead worm

drive. "

Few makes of appliances have received more careful thought in their construction than the Laces. The Lacre gully cmptior can be employed for cesSpool .work and it can be operated in . two distinct ways, known as , the open-circuit and closed-circuit systems. To operate on the ordinary vacuum system when foul gullies have te be entirely emptied, certain portions of the pipes are replaced so that a vacuum can be produced in the tank.

When working on the closed-circuit system, the tank is filled with clean 'water, and upon arrival at the gully the hose is lowered into it and water withdrawn from the tank is forced by a pump-through the dredging head; thus breaking up the solids in the gully, when they are drawn into the tank of " the machine. The operation continues until the, gully is cleansed, water then having displaced the sediment originally present. For cesspool emptying provision is made for expulsion of the contents under pressure through the medium of a four-way cock.

In the Karrier gully and cesspool emptier, a cylindrical tank to hold 500 gallons is mounted on the C.Y. type chassis. The tank, half filled with water, is partially exhauated of air ley means of an engine-driven pump, and the contents of the gully or cesspool are drawn into the tank, in which the water forms a trap and prevents the emission of obnoxious gases. A chain tackle enables the hose to be swung into position and serves to hold open the tank door during evacuation of the contents.

A 1,000-gallon Karrier model of similar design is also produced ; in this case the K.J. chassis is employed. The tank is of taper form and has a rear end door of the full diameter. The vacuum pump is of the opposed-cylinder type with a crankcase of aluminium and a crankshaft running on ball bearings.

The main tank of the .Lafily gully emptier is divided into two compartments, the npper receiving the sludge. This has a capacity of 1,100 gallons. It is arranged at a steeP angle to facilitate discharging and has a large door. The lower compartment contains 600 gallons of fresh water. A pipe connects the two and, when necessary, water may be introduced into the upper compartment to assist in the discharging or cleaning.

The Lallly pump is two-cylindered. It is a large and efficient unit mounted at the near side of the chassis and driven by a silent chain from an auxiliary shaft arranged in the gearbox. When dealing with very stiff sludge, water may be introduced into th.-: gully to assist in oosening the matter. While discharging, a special type of face valve controlling the air pump enables the vacuum to be released and the air pressure applied to the contents of the tank, which forces the discharge door open and delivers the contents on to the dump or into a barge.

Gully emptiers with tanks ranging from 600 to 1,300 gallons capacity are Utilized on the 4-ton, 5-trm and 6-ton Leyland goods chassis'. The equipment is of Eagle manufacture.

The Thornycroft gully and cesspool

emptying appliances work on the vacuum principle, the vacuum being created by means of a. mechanically. operated pump. Discharge is effected under pressure throfigh a valve underneath, and any desired length of hose can be attached to this valve when it is necessary to convey the contents to a point some distance from the machine. Suction lifts up to 26 ft. can be dealt with, and it i.9 possible to handle heavy sludge and semi-solid matter without trouble.

We have by no means exhausted the complete range of products in this class. Many of those makers whose chassis have not been referred to, because they have not specifically stated that they -can supply apparatus of this description, would no doubt quote for it if requested, as certain equipment, such as the Eagle, can be applied to almost any make of petrol or steam chetssis, whilst we learn that Commer Cars, Ltd., is now prepared to supply gully-emptier.