IlMechE Conference

Page 25

Page 26

Page 27

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

on auto transmission

Operators' message to boffins: work out the operating costs

WHILE automatic and semi-automatic gearboxes are confidently predicted for general use in heavy commercial vehicles by the manufacturers, operators are still in the dark on the comparative operating costs of manual v automatic transmission.

Few papers were based on actual operator experience at a recent conference at Solihull on automatic gearboxes. But those that were gave the manufacturers plenty to think about.

The conference was soon: sored by the automobile division of the Institution of Mechanical Engineers in association with the Institute of Road Transport Engineers. Several papers gave the views and experiences of vehicle and transmission manufacturers.

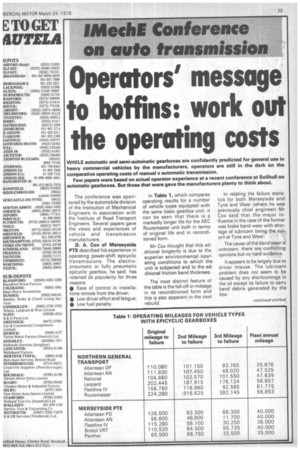

D. A. Cox of Merseyside PTE described his experience in operating power-shift epicyclic transmissions. The electropneumatic or fully pneumatic epicyclic gearbox, he said, has retained jts popularity for three reasons: • Ease of control in installations remote from the driver; • Low driver effort and fatigue; • Low fuel penalty. In Table 1, which compares operating results for a number of vehicle types equipped with the same basic gearbox unit, it can be seen that there is a markedly longer life for the AEC Routemaster unit both in terms of original life and in reconditioned form.

Mr Cox thought that this additional longevity is due to the superior environmental operating conditions to which the unit is subjected and to the additional friction band thickness.

The most distinct feature of the table is the fall-off in mile-age in its reconditioned form and this is also apparent in the next rebuild. In relating the failure statistics for both Merseyside and Tyne'and Wear (where he was previously chief engineer) Mr Cox said that the major influence in the case of the former was brake band wear with shortage of lubricant being the culprit at Tyne and Wear.

The cause of the band wear is unknown; there are conflicting opinions but no hard evidence.

It appears to be largely due to driver misuse, The lubricant problem does not seem to be caused by any shortcomings in the oil except its failure to carry band debris generated by the box. Arising from these observations Mr Cox said that development work has been carried out in three areas: • To limit the driver misuse of the box by automatic controls; • To improve the lubrication system or lubricant and thus the performance of components affected by oil quality, ie oil seals; •• To investigate the mechanics of band wear and the problems of overloading the lubricant with band debris, It is hoped, said Mr Cox, that by the adoption of automatic gearbox controls, driver abuse will be lessened and gearbox life and fuel consumption improved. However, considerable trade union resistance was encountered owing to resentment that full vehicle control had been taken away from the individual and a deterioration in _gear-change quality which occurred after a short mileage.

Mr Cox stressed that the manufacturers must pay greater attention towards improved gearbox longevity for future designs. "My paper is a complaint and a plea for help," he said. "It is unfortunate that the operator has had to do this development work, but the problem of reliability has reached crisis proportions.

"Regrettably, the manufacturer has not taken the same interest, as I feel that, with minimal redesign, the performance could be improved." Replying to some of Mr Cox's comments, W. J. Biggerstaff, chief engineer, Trist Draper Ltd, suggested that the debris problem is caused by the fact that the drum is not flat but carries a series of annular grooves. The band facing, however, was supplied flat.

Mr Biggerstaff argued that the debris is due to "the hefty machining operation" carried out on the band facing during the initial running period.

As far as band wear is concerned, he thought that defects in the air supply holding the bands cause this and not the design of the box itself.

"The transmission is last in line for the air supply after the brakes, the doors etc," said Mr Biggerstaff. He suggested fitting an air gauge to monitor the air supply to the gearbox.

No investigation

Although he agreed in principle with Mr Biggerstaff, Mr Cox said his point is that this procedure has been going on for years and has not been investigated.

Representing Mintex, H. Smales stressed that the brake bands need a V-groove form otherwise the torque capacity is much diminished.

"'Can't we start from first principles and design a clutch with the correct capacity? Put V-grooves on the friction lining as well as on the bands so we can start bedding-in immediately," said Mr Smales.

S. F. Burnett of British Leyland agreed that the airoperated gearbox is at the end of the line for air supply and its welfare depends entirely on its environment.

If it fails to receive its recommended air supply it will wear, he said.

''But that is only part of the story," he added," the problem being not the air pressure itself put the speed at which this pressure arrives."

In tests Leyland had found that in a poorly maintained box, it could take 11 seconds to reach the correct operating pressure, which meant that the bands had been slipping throughout this time.

On renewing the gearbox, the second life would be improved if the air system were overhauled at the same time, said Mr Burnett. "There is no reason why the replacement should not reach the level of performance of the original unit.—

"I think automatics have come to stay." That is the opinion of C. H. Curtis of London Transport who thinks that psv operators can never go back to the stepped cog transmission. He suggested that the mistake was to put automatic control on an existing gearbox.

Still representing the operator but this time on the lorry side, M. K. Filsell, chief en

gineer, Freightliners Ltd .scribed some of the compar tests, rnanual versus a matics, run by his compam

The Freightliner term network is based on the I centres of industry and poi tion, he said, and each ye can be expected to under three or more collectic delivery journeys per day gi an average annual mileag 33,000km (20,500 miles) the 600-vehicle fleet. A large proportion of this I congested traffic involving tinuous stop/start opera combined with short dist high speed motorway runni Freightliners' vehicle s fication requirements dude maximum load capaci minimum cruising speei 89km /h (55mph) and a I gear gradeability of at leas per cent to cope with the a short but steep ramps encc ered at customers' premiseE Mr Filsell quoted some c parative failure statistics fo. vehicles where it was indic that clutch and gearbox suffered badly on the ur operation with an average tance to failure of 48,000 135,000km (30,000 84,000 miles) respectively.

An alternative to the ma clutch/gearbox arrangemer obviously attractive, he said, the cost benefit of a fully /s, automatic gearbox vehicle iE critical factor to be proved.

Freightliners' trials

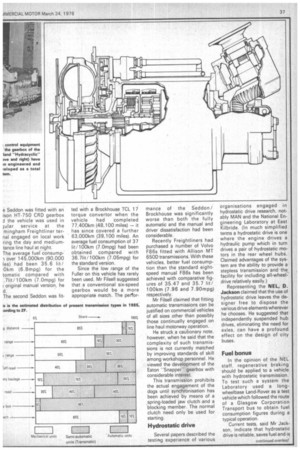

To get the facts for th selves, Freightliners stai trials with Seddon 34-Four 1 tive units whose orig specification had inclu Rolls-Royce Eagle 280 engii Lipe Rollway 381mm (15 diameter twin-plate clutc and Fuller 9509A gearbo: e Seddon was fitted with an ison HT-750 CRD gearbox d the vehicle was used in jular service at the Tningham Freightliner ternal engaged on local work ring the day and mediumlance line haul at night.

The average fuelconsump over 145,000km (90,000 les) had been 35.6 lit/ 10km (6.8mpg) for the tomatic compared with .71it /100km (7.0mpg) for original manual version, he d.

The second Seddon was fit ted with a Brockhouse TCL 17 torque convertor when the vehicle had completed 77,400km (48,100 miles) — it has since covered a further 63,000km (39,100 miles). An average fuel consumption of 37 lit/100km (7.0mpg) had been obtained compared with 36.71it/100km (7.05mpg) for the standard version.

Since the low range of the Fuller on this vehicle has rarely been used, Mr Filsell suggested that a conventional six-speed gearbox would be a more appropriate match. The perfor mance of the Seddon/ Brockhouse was significantly worse than both the fully automatic and the manual and driver dissatisfaction had been considerable.

Recently Freightliners had purchased a number of Volvo F86s fitted with Allison MT 650D transmissions. With these vehicles, better fuel consumption than the standard eightspeed manual F86s has been achieved with comparative figures of 35.47 and 35.7 lit/ 100km (7.96 and 7.90mpg) respectively.

Mr Filsell claimed that fitting automatic transmissions can be justified on commercial vehicles of all sizes other than possibly those continually engaged on line haul motorway operation.

He struck a cautionary note. however, when he said that the complexity of such transmissions is not currently matched by improving standards of skill among workshop personnel. He viewed the development of the Eaton -Snappergearbox with considerable interest.

This transmission prohibits the actual engagement of the dogs until synchronisation has been achieved by means of a .spring-loaded jaw clutch and a blocking member. The normal clutch need only be used for starting.

Hydrostatic drive

Several papers described the testirrg experience of various organisations engaged in hydrostatic drive research, notably MAN and the National Engineering Laboratory at East Kilbride, (In much simplified terms a hydrostatic drive is one where the engine drives a hydraulic pump which in turn drives a pair of hydrostatic motors in the rear wheel hubs. Claimed advantages of the system are the ability to provide a stepless transmission and the facility for including all-wheeldrive relatively easily.) Representing the NEL, D. Jackson claimed that the use of hydrostatic drive leaves the designer free to dispose the various drive elements wherever he chooses. He suggested that independently suspended hub drives, eliminating the need for axles, can have a profound effect on the design of city buses.

Fuel bonus . _

In the opinion of the NEL staff, regenerative braking should be applied to a vehicle with hydrostatic transmission. To test such a system the Laboratory used a longwheelbase Land-Rover as a test vehicle which followed the route of a Glasgow Corporation Transport bus to obtain fuel consumption figures during a typical operation.

Current tests, said Mr Jackson, indicate that hydrostatic drive is reliable, saves fuel and is acceptable to passengers in ride comfort during acceleration and deceleration.

Putting himself in the operators' shoes (which few of the other manufacturers' speakers did) 0. Holtermann of ZF said that the final customer must be fully convinced that an automatic transmission will be an advantage — both technically and economically.

Mr Holtermann described the advantages and disadvantages of semi-automatic and fully automatic transmissions as well as hydrostatic drive.

Theoretically, every commercial vehicle today can be equipped with a semi or fully automatic transmission, he said. However, he accepted that constant mesh or synchromesh gearboxes have certain advantages and will maintain a considerable market share in the future.

Mr Holtermann suggested. that the main applications of automatic transmissions in the foreseeable future will be for buses, urban transport, construction site and heavy haulage operation.

The control system of the gearbox rather than the gearbox itself was the subject of the paper given by K. E. Lea of British Leyland. He described a new Leyland range of hydraulically operated transmissions called -Hydracyclic" where the control equipment and the gearbox has been engineered and developed as a total system.

Mr Lea stressed that this is important as the characteristics of the control must complement the power train characteristics to achieve optimum results.

The Leyland automatic transmission, the 06, comprises a five speed hydraulically operated compound epicyclic gearbox complete with hydraulic coupling and retarder.

Mr Lea suggested that future generations of control systems will not only affect control of the transmission but also cover total -power train systems," controlling all those units which combine to provide the acceleration and deceleration of the vehicle.

In the general verbal free-forall which followed the conference many interesting points were raised.

A. Gurley of the National Bus Company said that the various transmission manufacturers' representatives had claimed that semi /fully automatic gearboxes will offer superior road performance. "Given this improvement," said Mr Gurley, "how far can we reduce our engine power to save fuel?"

Representing Voith, M. G. Gilbert said that no derating took place in Europe and that Voith has made no recommendations in this area.

"Suck it and see" was the suggestion put forward by C. H. Curtis of London Transport. This is what his company has done in trials with Voith gearboxes by derating by about five per cent, but he said he is wary of making this a general rule.

Axle ratio choice

Echoing the views of the operators present, R. M. Tuck of Detroit Diesel Allison said that it is necessary in effect to take away this extra performance provided by the transmission as the "extra" would use more fuel.

Mr Tuck suggested that a lower engine rating is only one of the choices, which include changing the axle ratio. He compared this problem with that caused by air deflectors which improve fuel consumption on a direct speed comparison basis but which also increase the top speed of the vehicle.

"As long as the driver has the option, he will trade it for performance,' said Mr Tuck.

In answering the plea from Professor D. E. Bowns of Bath University for a "like with like" comparison from the various manufacturers testing in relation to vehicle, route, weight, etc, Mr Lea of Leyland replied that the manufacturers would be delighted to do this if Professor Bowns would define, for example, a -standard route."

Putting in a plug for Commercial Motor, Mr Lea said that CM's Scottish test route is used as a standard for long haul vehicles but "nobody puts a 6x4 tipper round that route." He suggested that although a computer program could be used to predict performance as part of a paper exercise it still had to come back to reality

somewhere.

At the end of the conferer W. V. C. Batstone of 1 National Freight Corporat said that he thought there wc be a big increase in autom transmission in the next dec. in spite of some anxieties.

"I want to know what is cost of ownership against manual," said Mr Batstone. want to know the cost reliability. I want a compari! of durability. We have he little about any of this."

Talking about the lo awaited Eaton "Snapp( gearbox, Mr Batstone said he is not sure he wants to the extra 30 per cent that gearbox is supposed to c ''just for a bilge pump handle my drivers to play about with

Replying for the vehi manufacturers, W. Manninc Ford said his company is c. ting more involved in costs "the operators have bc shouting."

Mr Manning said that cc paratively speaking, there is a lot of expertise about automatic transmission applied to heavy lorries'.

As such transmissions very specialised subjects, o those people who can inves lot of money in design will co up with a low cost of owners added Mr Manning.

Mr Batstone hit the nail the head for the operator he mentioned that little fbeen said by the manufactur on the comparative operat costs of auto v manual.

A lot of questions were asl at Solihull; not many recei \ satisfactory answers.

• Graham Montgome