TESTING A BIG MORRISCOMMERCIAL PASSENGER CHASSIS

Page 50

Page 51

Page 52

Page 53

If you've noticed an error in this article please click here to report it so we can fix it.

WHEN Sir William Morris tackles a new branch of industry, no matter how closely allied to his other activities the project happens to be, he treats the new subject as a separate entity and sets up a specialized staff to deal with the whole

• of the problems appertaining thereto. The manufacture of commercial vehicles is a case in point. Despite a wonderfully organized factory at Omford, where private cars are built, Sir William set up another works at Soho, Birmingham, and staffed it accordingly for the production of goods vehicles. Later, passenger machines were contemplated, so another separate works came into being at Adderley Park, with a full staff of specialists in charge of affairs. Small wonder, then, that the products of such factories are considered by all knowledgeable operators to be at least as good as any competing concern's products built at home or abroad.

The foregoing paragraph is a fitting preface to our report on the behaviour of the large passenger-carrying chassis made by Morris Commercial Cars, Ltd.—a machine for 32-seater bodies, which incorporates a host of extremely interesting and practical features. To say that the vehicle is good in all respects is a summary of our findings; we were distinctly impressed by the riding qualities, the power and general smoothness in operation of the engine, the ease of operation of the controls and the steadiness of the vehicle when travelling at a fast pace on winding roads. The model which we took over was a forward-control machine equipped with an observationsaloon body and a test-load container in the form of an abbreviated lorry body. Normally intended for 32-passenger coachwork, the chassis has a wheelbase of 16 ft. 41 ins, and a body space of 20 ft. 11 ins. (measured from dash to end of frame). With a full equipment, including a spare wheel and tyre, the price is £925; another model, with normal control, is also available at £890.

Setting off from the iMorrisCommercial works at Adderley Park, Birmingham, we first of all tried the vehicle from the passenger's seat in the observation saloon. Even discounting the facts that the vehicle was fully laden and that we were sitting in a favourable position •somewhere amidships, this test of the suspension was convincing, for it was almost impossible for us to appreciate moderately rough or smooth road surfaces by the movement of the body. Natur ally the pounding of the wheels upon the road could be heard, but very little movement was passed on to the occupants of the seats.

Such was our first impression, and further acquaintance with the vehicle, both from the driver's seat and from the observation saloon, gave confirmation. A feature .which showed up early on in the test concerns the general behaviour of the power unit. As passengers we were baldly able to hear or feel when it was working hard, and even at speeds in excess of 40 m.p.h. remarkably little fuss was evinced by the engine, despite the fact that it was developing something in the order of 110 b.h.p. when working on full throttle. The gears, too, are quiet, likewise the remainder of . the transmission, and as squeaks are entirely absent from the braking system, we can affirm that all the qualities which make a good passenger vehicle are present in this the largest chassis produced by the Morris-Commercial concern.

Taking over the wheel after about 20 miles of mixed going, it was soon apparent that any normal driver should be able to take charge of the vehicle for long distances, because all the controls are light to the hands and feet and there is an absence of complications which is thoroughly desirable. A close inspection of the chassis reveals the fact that this characteristic is no accident, for all parts have clearly received a great deal of thought in the manner in which they have been planned to give efficient operation, and, what is very important in a commercial vehicle, ease of maintenance.

Take, for example, the steering gear. The actual wheel movement is beautifully light and yet there is a directness and accuracy about this control which makes driving quite pleasant. Unquestionably, the manner in which the swivels are mounted on button-type thrust pads (which are practically frictionless and are always immersed in oil) and the fact that the pivot angles have been carefully considered to give the correct castor action, are very important features.

There are several items in the transmission which assist in making gear changing a simple matter. Not only are the friction faces of the single-plate clutch no less than 4 ins. wide (so that a relatively light spring pressure can be used), but in addition the friction material is riveted to the flywheel and pressure plate to keep the weight of the free member as small as possible. In passing it Might be mentioned that the design of the withdrawal gear incorporates four multiplying levers in order that the pedal action should be as light and free from distortion as possible. To assist in making rapid upward changes a band-type clutch stop is fitted and is provided With an adjustment which is accessible from outside the casing. This takes the form of a self-locking hand wheel situated immediately under the floor hoards of the driver's compartment.

Gear Ratios Well Chosen.

The gear ratios appear to have been wisely chosen. On top gear, even with the chassis somewhat overladen, we found that most mainroad hills could be taken in the stride of the vehicle without a marked slackening in speed, provided that the early parts of the gradient were taken reasonably fast. It appears to us that it would be seldom necessary to employ a lower gear than third for main-road work, and second for any hill likely to be encountered on an ordinary coach or motorbus route—in this country at any rate.

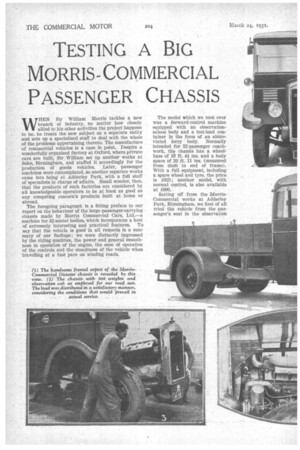

The choice of gear ratios is reflected in the speed capabilities of 534 the vehicle. Although the maximum rate of travel attained during a whole day's run was only slightly in excess of 50 m.p.h., the engine evinces marked pulling powers at 35 m.p.h. to 45 m.p.h., and in our view such a performance is to be preferred to one where an inordinately high maximum is available to the exclusion of good accelerative powers in the low and middle ranges.

Conforming with modern practice on high-grade vehicles, six sets of brake shoes are provided; the pedaloperated set consists of four pairs of internal-expanding shoes affecting all road wheels, whilst the hand-lever controls separate shoes in the rearwheel drams only. The pedal-applied system incorporates one Dewandre vacuum servo motor and, whilst the braking effort is very powerful, the pedal pressure is not heavy ; furthermore, there is very little delayed action between the instant of application of the pedal and the time when the brake -shoes actually cause a retardation of the vehicle. A single-point self-locking adjustment located outside the frame is provided for the foot brake and a similar adjustment for the hand brake is positioned under the floor boards of the driver's compartment. These, combined with what might be termed a garage adjustment for All six brakes (on the rear-brake rods and on the front-brake shoes), greatly assist the operator and driver in keeping the vehicle continually on the road.

The Ingenious Power-unit Mounting.

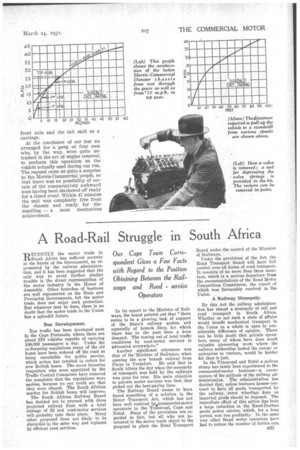

One of the most interesting features of the Dictator chassis is to be found in the mounting of the power unit, for by an ingenious arrangement, often referred to in this journal in the past, the engine, clutch, gearbox and radiator assembly can be detached from the vehicle in a very short time by uncoupling a small number of parts.

Actually the power unit is carried on the front-frame cross-tube in a trunnion bearing, the tube also carrying the radiator. Two arms cast on the clutch housing carry spherical seatings which rest in mountings formed in the front-spring shackle brackets. The removal of the unit is accomplished by disconnecting the exhaust pipe, the fuel pipe and controls, the side steering rod and one end of each spring-recoil absorber, removing the gearbox lid complete with its control, and the setscrews anchoring the spring brackets to the main frame. A tail skid is provided in the tool kit for mounting under the gearbox so that the whole unit, Including the radiator, can be rolled out on the front wheels, using the front axle and the tail skid as a carriage.

At the conclusion of our test we arranged for 'a gang of four men who, by the way, were quite untrained in the art of engine removal, to perform this operation on the vehicle actually used during our run. The request came as quite a surprise to the Morris-Commercial people, so that there was no possibility of certain of the comparatively awkward nuts having been slackened off ready for a timed event. Within 47 minutes the unit was completely free from the chassis and ready for dismantling — a most meritorious achievement.