PNEUMATIC TYRES FOR PASSENGER TRANSPORT.

Page 24

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

Why the Straight-sided Tyre is Preferred. How Manufacturers Give Guidance and Service to Users.

DURING the past year or two, great strides have been made towards the perfection of the pnedmatic tyre, one of the most interesting developments being the production of the straight-side type. In this connection it is worth remembering that the vehicles on which the War Office pays a subsidy have to be equipped in such a manlier that a standard War Office disc wheel and appropriate straight-side tyre can be fitted and that, if and when the vehicle is taken o-.3r by the War Office, it will be fitted by them with straight-side tyres, no matter what equipment is used for commercial work. This War Office decision to use straight-side pneumatic tyres where pneumatic tyres are used for war transport, was taken purely on th3 merits of the type, so that the ordinary used has a strong lead as to the direction in which opinion is tending.

Unlike the beaded-edge cover, the straight-side tyre is designed so that it does not rely on the maintenance of the inflation pressure-t6 hold it firmly to its rim, this adherence being obtained by incorporating in each edge of the outer cover a stout ring of braided steel wire, possessing a tensile strength of over 20 tons in the model for use on chars-a-bancs. 's these edges are inextensible and cannot be stretched over the upstanding sides of the rim, the only method of removing the tyre from the rim is to • make one of the rim flanges detachable. • In practice this is achieved with a flat base rim, one flange of which is fixed upright and curves outwards. The other outwardly curved flange is detachable, and is made in the form of a loose ring which fits on the rim and is locked by a split steel ring, xvhich is sprung into a gutter on the edge of the rim. It is claimed that, by this construction, it is impossible for the tyre, even when deflated, to leave the rim, and that the safety of the vehicle is, therefore, secured. Furthermore, the champions of the straight-side-type point to the fact that, given equal sizes, it has a larger air capacity and, therefore, produces a. greater degree of comfort than the beaded-edge type.

The application of straight-side pneumatic tyres to commercial vehicles is standardized by a number of British manufacturers, whilst it is possible, in cases where standardization is not. in force, for purchasers to specify pneumatics at the time that a new vehicle is ordered. • In this connection,' it is interesting to note that the Dunlop Rubber Company maintain in their technical advisory division a staff which has made a study of the problems appertaining to tyres for use with heavy transport, and is willing to offer advice and knowledge freely to any owner who wishes to know what is the most efficient and economical

• tyre equipment for the particular conditions with which he is faced.

To an expert, conversions from solids to pneumatics are comparatively simple. New wheels are always required, having the straight-side rim equipment incorporated, while modifications to existing hubs, clearances and steering lock may also have to be considered, in view of the difference in dimensions between the old and the new equipme i. Lastly, the load to be carried must be considered as well as the type of vehicle to which the new equipment is to be fitted, in all of which points the value of assistance from a trained specialist advisory staff is obvious. Let us take the case of an owner who contemplates the use of straight-side pneumatics on his vehicle. In the first place, he communicates with the tyre makers, who will then make him a proposition and 040 submit a complete scheme. In the case of the Dunlop Co., it is perhaps worth noting that "beadededge" convessions will not be supplied in any circumstances, as they consider the beaded-edge form of attachment is not capable of giving maximum safety, durability and economy in the hands of users generally. The first point to be considered when discussing a conversion is to secure a tyre of correct section. A giant pneumatic, for instance, depends for its success on its ability to carry the load, and in this connection it is gratifying to be able to state that, generally speaking, there has been less under-tyring on British cars with giant pneumatics than on any other type of vehicle. Those who have taken expert advice when considering conversions, have been amazed by the wonderful service which the tyres have given, a point which shows the value of consulting a specialist before deciding definitely on any type of equipment. The second point is to decide on the best type of Lyre. A growing body of opinion prefers the straight-side for reasons which have been given above. In the case of the Dunlop Co.; over 250 conversions to straight-side pneumatics have been effected since October last, quite a number of these having been from beaded-edge.

Where the Manufacturer Can Help the User.

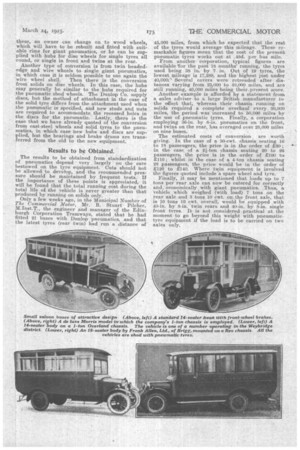

Having established touch with the tyre maker, it will probably be necessary fothe owner to supply the manufacturer with, among other details, the make of the vehicle, the type of chassis and horse-power, the year of manufacture, the type of body, the size of solid tyres now fitted, the type of present wheels, and the condition of the roads over which the vehicle usually runs. r.lhe tyre company will then be able to offer suitable equipment for any particular case. The most popular typo of wheel for pneumatic equipment is the disc, which las achieYed success because of its simplicity and the fact that it is most 'easily .adapted for twin equipment, and for the carrying of a spare as well as being more easily handled than a 'demountable rim.

Let us consider the case of a tyPiCal conversion to disc wheels. It will involve the purchase of four hubs, which will be supplied by tUe tyre makers.. The owner will remove his existing wheels and then transfer his bearings to the new hubs, whilst, in the case of the rear hubs, he will almost always have to transfer the brake drums from the old wheels to the new hubs. The latter will then fit the axles exactly as they did when the old wheels were in use.

The new hubs are made to receive disc wheels, the latter being. classified according to the number of bolt-holes, 1.e., 6, 8 or -10, which they possess, a. point worth noting being the fact that all the chief makers of disc wheels have standardized their productions so as to be interchangeable and classed them by the ntimber of bolt-holes they possess. The number of bolt-holes is decided by the diameter of the driving plate on the back wheel, the point aimed at all the time being that the owner uses a maximum of his old equipment and can, therefore, draw direct from the chassis manufacturers rather than the tyre manufacturers for spares when occasion

arises. • There are several different types 'of Conversion now in common use, a popular one being the change over from wood wheels with solid tyres. From these, an owner can change on to wood wheels, which will have to be rebuilt and fitted with suitable rims for giant pneumatics, or he can be supplied with hubs for disc wheels for single tyres all round, or single in front and twins at the rear.

Another type of conversion is from twin beadededge and wire wheels to single giant pneumatics, in which case it is seldom possible to use again the wire wheel shell. Then there is the conversion from solids on disc wheels. In this case, the hubs may generally be similar to the hubs required for the pneumatic shod wheels. The Dunlop Co. supply discs, but the method of attachment in the case of the solid tyre differs from the attachment used when the pneumatic is specified, and new studs and nuts are required to accommodate the recessed holes in the discs for the pneumatic. Lastly, there is the case that we have already quoted of the conversion from cast-steel wheels and solid tyres to the pneumatics, in which case new hubs and discs are supplied, but the bearings and brake drums are transferred from the old to the new equipment.

Results to be Obtained.

The results to be obtained from standardization of pneumatics depend very largely on the care bestowed on the tyre equipment. Cuts should not be allowed to devetop, and the recommended pressure should be maintained by frequent tests. If the importance of these points is appreciated, it will be found that the total running cost during the total life of the vehicle is never greater than that produced by running on solids only.

Only a few weeks ago, in the Municipal Number of The Commercial Motor, Mr. R. Stuart Filcher, M.Inst.T., the engineer and manager a the Edinburgh Corporation Tramways, stated that he had fitted 21 buses with Dunlop pneumatics, and that the latest tyres (rear twin) had run a distance °I

45,000 miles, from which he expected that the rest of the tyres would average this mileage. These remarkable figures mean that the cost of the present pneumatic tyres works out at .48d. per bus mile. From another corporation, typical figures are available 'for the past 18 months' running, the tyres used being 38 in. by 7 in. Out of 19 tyres, the lowest mileage is 17,289, and the highest just under 40,000:' Several covers were. retreaded after distances varying from 23,000 to 40,000 miles, and are still running, 40,040 miles being their, present sore.

Another example is afforded by a statement from a sales adviser to a large British manufacturer to the effect that, -whereas their chassis running on solids required a complete overhaul every 20,000 miles, the period was increased to 50,000 miles by the use of pneumatic tyres. Finally, a corporation employing 36-in. by 6-in, pneumatics on the front, and twins on the rear, has averaged over 28,000 miles on mine buses.

The estimated costs of conversion are worth giving. In the case of a 30-cwt. chassis seating 16 to 18 passengers, the price is in the order of £80; in the case of a 2A-ton chassis seating 20 to 26 passengers, the price is in the order of 2100 to £110; whilst in the case of a 4-ton chassis seating 28 passengers, the price would be in the order of £120 to £140. Where twin equipment is involved the figures quoted include a spare wheel and tyre.

Finally, it may be mentioned that loads up to 7 tons per rear axle can now be catered for correctly and, economically with giant pneumatics. Thus, a vehicle which weighed (with load) 7 tons on the rear axle and 3 tons 10 cwt. on:the front axle, that is 10 tons 10 cwt. overall, would be equipped with 40-in. by 8-in. twin rears and 40-in. by 8-in, single front tyres. It is not considered practical at the moment to go beyond this weight with pneumatictyre equipment if the load is to be carried on two axles only.