TREADING CAREFULLY

Page 101

Page 102

If you've noticed an error in this article please click here to report it so we can fix it.

Tough times continue for Britain's tyre manufacturers. The market is static and the pressure from importers continues to squeeze home-grown sales — there is a surprising air of confidence about the future.

• Just under two million commercial vehicle tyres are sold on Britain's replacement market every year. A further 500,000 to 600,000 new tyres are fitted on production line vehicles yet, despite the total output, things are not booming for the tyre manufacturers.

Life in the 1980s has been tough for the tyre producers, with major names like Dunlop having to fight hard to survive. Yet confidence is tentatively returning to the market and most of the manufacturers now seem relatively bullish about the future.

Though there have been few dramatic product developments in recent years, new tyres continue to appear at regular intervals and all of the major manufacturers have new tyres waiting in the wings. Business is competitive and the manufacturers arc secretive, both about their market shares and future products. General trends are easier to spot, however.

The four-wheel-drive market, for instance, is spurning a new range of high performance, excellent traction on/offhighway tyres. Fuel costs have increased so much that the majority of professional hauliers now demand economic tyres.

According to Pirelli's marketing man

ager Chris Farnworth, attitudes have changed: "Operators no longer think a tyre is just a black rubber ring in every corner." The fact that properly specified and maintained tyres save money seems to be an increasingly popular doctrine.

There is also a slow but steady shift to low profile tyres in the UK. Our continental competitors are way ahead of us here, and Goodyear's marketing manager Steve Waiting thinks that the longer Britain delays its switch to 40 tonnes, the less likely we are to change. The best selling tyre size in the UK remains the standard profile 11R 22.5 (the '11' designates the section width of the tyre — 11in in this case, the 'R' denotes a radial and the '22.5' refers to the overall rim diameter of the tyre — 22.5in).

New metric sidewall markings are coming in too. To give a low profile example to balance the argument, let's look at a 315/75 R 22.5. This means the tyre has a section width of 315mm, a cross-section ratio, or profile, of 75%, a radial construction and a rim diameter of 24.5in.

Farnworth thinks that low profile tyres have got to come. They help keep the truck's load height to a minmum, have a lower cost-per-kilometre, run cooler and offer better braking performance. Pirelli is keen to point out that on a 22.5in diameter tyre, for example, cooler running and better braking performances are achieved because the low profile tyre gives an extra 5cm (2in) across the whole diameter of the tyre, allowing more air to swirl around the brake housing. With the increasing use of disc brakes and the additional space needed by disc designs, low profile tyres have an obvious advantage.

• GOODYEAR

Goodyear is the world's biggest tyre manufacturer and it remains a successful force in the UK commercial vehicle market.

Its G167 drive-axle-only tyre and the multi-purpose G291 remain best sellers for the group. The G167 now offers extra tread depth for improved traction. Goodyear is closely monitoring the trend among light truck manufacturers towards low profile tyres. According to Waiting, the 85 R 17.5 size has dominated the Leyland Roadrunner class for some time now, but tyres such as the 205 and 215/75 R 17.5 are becoming more popular. He predicts that the van tyre of the future will be the 215/65 R 15 and Goodyear is working with a number of major European truck producers to include these tyre sizes in their range.

High-line coaches mean that low profile tyres have already taken hold of the PSV market, says Waiting, with the 295/80 R 22.5 size dominating sales. Keeping the coach's centre of gravity as low as possible has led to this switch in the 80 Series size class.

Those of you running four-wheel-drive vehicles should also watch out for a new model from Goodyear. The company's 225/75 R 15 Wrangler tyre is already standard on the Mercedes G Wagen and a new option will soon be on view.

• PIRELLI

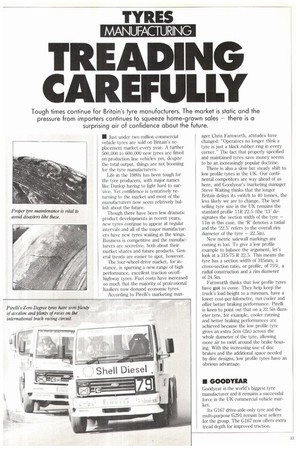

Pirelli continues to increase its presence in the UK's commercial vehicle tyre market, though the firm admits it did start from a very low base. Its new "Zero Degree" low profile tyre design is doing well. Pirelli makes roughly 2.5 million truck tyres a year and the Zero Degree tyres will soon replace the whole range.

Pirelli has spent a lot of time and effort promoting its Zero Degree technology on the truck racing circuit in Europe where most of the winning vehicles now use Pirelli tyres. The company claims it has never lost a major race.

The Zero Degree nametag refers to two steel belts running parallel to the tyre's direction of travel and reinforcing the critical shoulder area of the tyre. This extra bracing reduces distortion, thus keeping the tyre's temperature low.

Radial plies run at 90 degrees to the Zero Degree construction method. Pirelli also points out that the Zero Degree unit is designed with remoulding in mind.

The only trend in the UK tyre scene is the increasing number of imports, says Pirelli's Chris Faimworth "and overall tyre demand is remaining static." Pirelli's slice of that static cake is getting bigger and the firm seems confident. It is planning to take on more workers at its manufacturing plant in Burton-on-Trent and has revamped its remoulding facilities.

Pirelli now offers a hot and cold cure retread service at Burton, where it repairs customers' casings as well as selling remoulds from stock.

The hot and cold remould service includes bead-to-bead and shoulder-toshoulder retreads: the company reckons the cold cure retread is less likely to damage the tyre carcass through heat build-up.

Pirelli will spend £35 million over the next five years refurbishing its Burton-onTrent and Carlisle plants.

• MICHELIN

Michelin, Europe's biggest tyre manufacturer, is now pressing ahead with its recently-launched XZA wide single trailer tyre, available in a 385/65 R 22.5 size. The tyre, which is wide and flat in section with five grooves, will help cut down the problem of uneven scrubbing wear on triaxle semi-trailers, says Michelin. The company adds that the tyre is achieving good market penetration.

• CONTINENTAL

Continental's much-vaunted EOT tyres (Energy Optimised Tyre) are now on sale in the UK, having had their official European launch in the middle of last year. Operators can now put the Continentals to the test — the firm reckons that the tyres offer a 5% fuel saving. The EOT has a new type of belt design which employs "low damping" in a highly elastic rubber compound fitted in layers between the tyre's normal carcass belts.

Rolling resistance should be cut by 18%, says Continental, and the tyre should last longer because it does not deform badly at high speed.

• AVON

Avon claims to be the only tyre manufacturer to have been awarded the BSI Quality Assurance Certificate. It offers the drive-axle Powermaster and the all-round 16.5mm tread depth Steermaster AR 160. The group, based in the west country, also offers the 18mm tread-depth Drivemaster AR130 for on and off highway applications.

• DUNLOP (SP)

Ian Payne, director for commercial vehicle tyres at SP Tyres (the born-again Dunlop tyres company), looks forward to the day when there are far fewer tyre variants than there are now. He sees a need for just two basic types in each size: a traction tyre and a steering-axle tyre. SP recently introduced new drive-axle and steering-axle tyres — the SP431 and EP 321 respectively. The SP431, in particular, has an exceptionally deep tread pattern to give a much longer first life.

SP's research into future tyres at its Fort Dunlop, Birmingham, headquarters involves some 67 different test cells and machines testing everything from endurance to road noise. Roger Williams, general manager of truck tyre development, says a great deal of work is being done on noise and wear, but points to variations in road surface as being confusing to the development engineers. For example, he says, the difference between smooth and rough asphalt has as much significance on tyre performance as does the difference between a radial and a cross-ply tyre.

Williams is convinced that there is a future for more advanced tyre designs, especially unidirectional tyres. What he does not predict is a move to asymmetric designs.

As with many other manufacturers, SP sees tyres for triaxle trailers as offering the real challenge. The best compromise between scrub resistance, life and grip on 15R22.5 tyres has yet to be established and Payne is not keen on solutions like different mixes for the different axles of a triaxle. Triaxle tyre problems are taken seriously at SP: all carcasses coming in for retreading go through the holographic equipment normally used for research and production quality control to ensure their integrity.