Prof. Timoney the diesel puts a case for

Page 48

Page 49

Page 50

If you've noticed an error in this article please click here to report it so we can fix it.

Experimental work at University College Dublin gives promise of outstanding four-stroke diesel developments as well as a super lightweight high-output VCR opposed-piston two-stroke.

'WHAT are you waiting for?" I asked Prof. S. G. Timoney, Mechanical Engineering Department, University College Dublin, during a recent visit to the college. We had been discussng the merits of the Timoney op-' posed-piston two-stroke engine which is of the variable-compression-ratio type based on the Rootes TS3 unit and equipped with turbo chargers in series. .

I asked the question because the performance of the Timoney three-cylinder engine appeared to merit immediate application to a road vehicle. It produces more than double the horsepower of a standard Rootes engine, has an acceptable fuel consumption and a good torque back-up. The maximum b.m.e.p. of the unit is around 250 psi. which is equivalent to a b.m.e.p. of 500 psi. produced by a four-stroke engine. Peak cylinder pressure is approximately 1,800 psi. and the compression ratio is varied automatically between 9 to 1 and 18 to 1 according to changes in cylinder pressure. Although a power output of nearly 300 bhp is obtainable when operating on a 9 to 1 compression ratio compared with 130 bhp available when operating at a ratio of 16 to 1 the mechanical and thermal loading of the unit is approximately the same in both cases.

The gain in power at the same stress level provided by operating on high boost with a low compression ratio is a function of the pressure /volume characteristic of the combustion cycle. Lowering the compression ratio and increasing the fuelling rate gives a PV diagram that is more nearly a constant-pressure diagram, than that provided by the mixed constant-volume /constant-pressure cycle of the conventional diesel. While the peak pressure is reduced and the rate of pressure rise is increased, a high pressure is maintained over a greater crank angle.

In reply to my question Prof. Timoney said that production of the engine would necessitate complete re-tooling of the Rootes production line, and unless Rootes or another manufacturer were prepared to mount such a major exercise, the project was not practical. But assessment of the unit's potential did not end on this negative note. Later in my visit, Prof. Timoney said that a double-bank highoutput version of the engine coulcl be produced that would occupy half the space of an equivalent gas turbine (complete with heat exchangers) and would have approximately the same weight. It would have a more favourable fuel consumption throughout the load /speed range and would cost less to produce. The power-to-weight ratio would be about 21b /bhp.

I had visited Prof. Timoney with my diesel hat on to get chapter and verse on the merits and prospcts of the Timoney engine in competition with future generations of gas turbine, notably the Leyland gas turbine which was the subject of a technical assessment in CM, January 10 1969.

Wider interest

While assessing the potential of the doublebank Timoney unit would obviously be pertinent to a review of the gas turbine /diesel controversy at this stage, reviewing the potential of detailed experimental work at University College and of Prof. Timoney's thoughts for the future possibly has a wider interest in that it relates to the potential of the conventional four-stroke diesel as well as the two-stroke. The role that could be played in the development of the diesel by the hydraulically driven Pelton wheel used by Prof. Timoney to add auxiliary energy to a turbocharger shaft in turbocharger/engine matching could be of outstanding importance. And interest in forecasting the part it could play in the development of automotive power units is heightened by Prof. Timoney's claim that it could profitably be applied to petrol engines.

A hydraulic turbine of the Pelton-wheel type is incorporated in the system of the Timoney opposed-piston engine. The Pelton wheel has a diameter of 11in. and the space between the turbine and compressor occupied by the wheel and nozzle is negligible. A mechanically driven fixed-capacity pump is employed to supply fluid in the form of engine oil to the Pelton wheel which can be employed to drive the turbochargers to increase the torque output of the unit, notably at low loads. Employing a variable-delivery pump would greatly enhance the scope of the system in some applications.

A Pelton-wheel turbine essentially comprises a series of small buckets arranged round the periphery of a rotor and a jet of fluid from a nozzle is discharged into the buckets at high velocity to produce torque. Driving a turbocharger with a Pelton wheel is a cede of driving a turbine with a turbine both of which have, of necessity, a high operating speed.

In the application to the experimental two stroke engine it takes the place of the conventional scavenge blower. It enables the engine to be started and to be operated at tick-over speeds without a blower. Although it absorbs about 12 bhp at maximum output, the power-loss penalty at part load is consequently a fraction of the normal penalty. Moreover, it eliminates acceleration delay and provides a greater rate of acceleration throughout the load/speed range. In an observed test of the engine the elapsed time between acceleration from tick-over speed to maximum-power speed was very substantially reduced when the Pelton wheel was operative.

Impossible to match

Prof. Timoney points out that it is impossible to match a turbocharger to a four-stroke power unit to provide a "really worth while" torque back-up without de-rating the engine power. While the use of an exhaust-wastegate turbocharger offers a possible means of increasing torque at low rpm without overloading the engine at high rpm, a turbocharger of this type cannot provide for optimum matching. A turbocharger can, however, readily be matched to increase torque at high or medium rpm: a mechanically driven supercharger has been employed by a number of engine manufacturers to boost torque at low rpm but this incurs a serious wastage of power because the supercharger continues to operate at higher speeds when it is not required.

A Pelton wheel driven by a variabledisplacement pump could be employed to increase the torque of the engine at low rpm over a predetermined part of the load /speed range or over the entire range. In a typical application, the turbocharger could be matched to the engine to give a constanthorsepower characteristic over a speed range of, say, 1,000/2,500 rpm. Although useful power would be absorbed by the Pelton wheel when it was operating at or near its maximum output this would be more than offset by the reduction in the number of gear ratios required. By employing a suitable control unit the turbocharger /Pelton-wheel system could be designed to give maximum economy at cruising speeds. No power would be wasted when it was inoperative.

The Pelton-wheel turbine should, therefore, have a big potential as part of a relatively simple system that would be applicable to every type of four-stroke automotive diesel. If the compression ratio of the engine were variable, its potential would match that of the Timoney two-stroke engine.

Whereas the compression ratio of the opposed-piston two stroke can be varied by angular movement (controlled by spring-loaded struts) of eccentrically mounted pivot shafts on which the rocker arms oscillate, varying the ratio of a four stroke would necessitate the use of a VCR piston, suleh as

the BICERI type. This is a well-proven piston but is relatively heavy and costly. Many other forms of VCR piston or system have been patented over the past 30 years.

In place of using a VCR system, an engine could be equipped with a device to reduce the compression ratio to the optimum ratio for full power after the engine had been started on a higher ratio, a high ratio being required for starting. Although this would enable a greatly increased power output to be obtained at a given stress level (given that a sufficient boost pressure were available), the power-output advantage would be offset by a sacrifice in economy at part-load conditions. The optimum part-load compression ratio of the Timoney engine over a fairly wide range is 14 to 1 and operating continuously at 9 to 1 would increase fuel consumption by a substantial amount. It is known that a number of engine manufacturers experimenting with VCR pistons have obtained approximately twice the power of the standard engine.

Weaker mixture

In Professor Timoney's view a VCR /Peltonwheel system could be applied to a diesel engine to allow it to run on a varying-quantity but constant-quality charge, as the petrol engine does, but without the part-load pumping losses that throttling incurs. A weaker mixture than a stoichiometric (chemically correct) mixture would be used, say, 20 to 1 up to 23 to 1, to give better thermal efficiency than the petrol engine. With the controlled assistance of the Pelton-wheel drive to a turbocharger, large excesses of air (which do not give a real return for their parasitic power drain) would be avoided. At the same time the compression ratio would automatically be adjusted to match changes in the quantity of the charge. And this combination would reduce pumping losses and give improved fuel consumption.

Where a higher specific power output is required and somewhat lower efficiency is acceptable the same basic engine concept could be used with a stoichiometric mixture and the use of spark ignition with a lower, but variable, compression ratio.

If a VCR piston of an acceptable type were available it could profitably be used in conventional spark-ignition engines to increase the ratio to the extent that the intake air were throttled. On full load, the engine would oper ate on its minimum compression ratio of say 8/9 to 1 and when running on very light loads the ratio could be increased to possibly as much as 17/18 to 1 in a typical case which would give a very substantial improvement in fuel consumption.

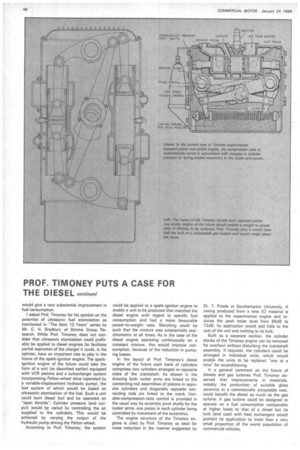

I asked Prof. Timoney for his opinion on the potential of ultrasonic fuel atomization as mentioned in "The Next 10 Years" series by Mr. C. H, Bradbury of Simms Group Research. While Prof. Timoney does not consider that ultrasonic atomization could profitably be applied to diesel engines (to facilitate partial aspiration of the charge) it could, in his opinion, have an important role to play in the future of the spark-ignition engine. The sparkignition engine of the future could take the form of a unit (as described earlier) equipped with VCR pistons and a turbocharger system incorporating Pelton-wheel drive (operated by a variable-displacement hydraulic pump), the fuel system of which would be based on ultrasonic atomization of the fuel. Such a unit could burn diesel fuel and be operated on "open throttle". Cylinder pressure (and output) would be varied by controlling the air supplied to the cylinders, This would be achieved by varying the output of the hydraulic pump driving the Pelton wheel.

According to Prof. Timoney, the system could be applied to a spark-ignition engine to enable a unit to be produced that matched the diesel engine with regard to specific fuel consumption and had a more favourable power-to-weight ratio. Matching could be such that the mixture was substantially stoichiometric at all times. As in the case of the diesel engine operating continuously on a constant mixture, this would improve consumption, because of the reduction in pumping losses.

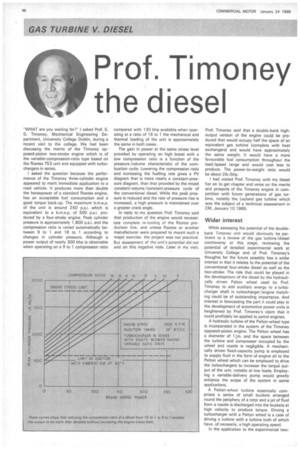

In the layout of Prof. Timoney's diesel engine of the future each bank of cylinders comprises two cylinders arranged on opposite sides of the crankshaft. As shown in the drawing both rocker arms are linked to the connecting-rod assemblies of pistons in opposite cylinders and diagonally opposite connecting rods are linked to the crank. Variable-compression-ratio control is provided in the usual way by eccentric pivot shafts for the rocker arms, one piston in each cylinder being controlled by movement of the eccentrics.

The engine structure of the Timoney engines is cited by Prof. Timoney as ideal for noise reduction in the manner suggested by Dr. T. Priede at Southampton University. A casing produced from a new ICI material is applied to the experimental engine and reduces the peak noise level from 85dB to 72dB. Its application would add little to the cost of the unit and nothing to its bulk.

Built as a separate section, the cylinder blocks of the Timoney engine can be removed for overhaul without disturbing the crankshaft assembly. If required, the cylinders could be arranged in individual units, which would enable the units to be replaced "one at a time" for reconditioning.

In a general comment on the future of diesels and gas turbines Prof. Timoney observed that improvements in materials, notably the production of suitable glass ceramics at a commercially acceptable cost, could benefit the diesel as much as the gas turbine. A gas turbine could be designed to operate on a fuel consumption comparable at higher loads to that of a diesel but its bulk (and cost) with heat exchangers would prohibit its application to more than a very small proportion of the world population of commercial vehicles.