Define your haul

Page 63

Page 64

Page 65

Page 66

If you've noticed an error in this article please click here to report it so we can fix it.

The operator's first decision is: What deck length do you need to carry your basic load?

ECIFYING the right -fide for the right job is rely one aspect of staying he transport business and, 3efully, making a profit.

ro find out some of the nkles involved in selecting heavies (which, as far as this cle is concerned, means 24 s and over) I talked to Ron nstrong, sales applications nager of Leyland's Heavy licle Division.

In Ron Armstrong's opinion first place to start is for a ential buyer to explain the ure of his operation over the bable life of the vehicle. And ) to take a guess at what sort new business may come his y. of new business may come his way.

The first basic decision to make concerns deck length and this revolves around the size of the basic load. Boxes or pallets? Bulk? Is it indivisible or not? As far as this length goes anything more than 26ft or 27ft and we're straight away into an artic.

Legally the artic is limited to 15m (49ft 2in) in overall length with the "standard" semi-trailer length giving a usable load space of around 12.2m (40ft). For general haulage, the flexibility of such an outfit is almost unbeatable, especially when it is linked with the ability to go to the maximum UK gross weight limit.

But, as Ron Armstrong said: "If people have a length problem with the load, they are often brainwashed into thinking artics. There is still plenty of general haulage done with 16tonners."

If the transport of the goods is directly matched to their production it is easy to think yourself into a box and carry on with a particular type of vehicle, be

cause of tradition as much as anything else. So a look into the various choices — solo rigid, artic, demountable, drawbar — might not be a bad idea.

Where is the load coming from and where is it going?

It may sound rather like stating the obvious, but it's no good going for a maximum length outfit — be it rigid or artic — if the layout of the depot or the delivery area automatically limits you to an Escort van. Traffic congestion is something that can generally be ignored as most heavy commercial vehicles are relatively ungainly anyway.

Because of the accessibility problem, very few operators go for maximum length (11m or 36ft lin) rig ids. In fact as far as the Leyland sales figures go, long-wheelbase rigids account for less than five per cent of the sales total with the tipper preponderance for short-wheelbase models keeping the average down.

If space isn't a serious problem then you can have a body length of around 301t on a rigid which is applicable to four, six or eight-wheelers. But if space for manoeuvring is a critical factor then toe maximum length rigid is not for you.

In Ron Armstrong's view there is a lot to be said for drawbar outfits with demountable bodies. He told me: "I can see a lot of people comparing artics against demounts with their two .20ft bodies."

He still thought, however, that the artic would hold supreme while our existing 32 ,tons limit applies. With loads in the cornfalkes and potato crisp category, and the load space available then a drawbar is an attractive proposition. With an overall length limit of 18m (59ft lin) it is not too difficult to achieve around 48ft of load space.

On the Continent, the European operators with their higher gross weights, have reached the deck-length problem before the UK, which is one of the reasons why the rigid/trailer outfit is more popular than in Britain.

32 v38

Most of the manufacturers competing in the top-weight tractive unit/semi-trailer market offer both a "light-weight" and a "heavyweight" version, with two classic examples being Leyland with the Buffalo and the Marathon and Volvo with the F86 and the new F10. Obviously this is once again a direct result of the UK maximum weight limit, as the Buffalo is restricted to 32 tons by design whereas the Marathon is restricted by legislation.

asked Ron Armstrong if there were any basic guidelines as to which specification to go for assuming UK operation.

"The way we're set up, we've got a choice of style for the artic — Buffalo or Marathon — with superficially not much to choose between them. Take the Buffalo with the 511 engine giving 230 horsepower and the 6.35 axle ratio. This will do 61 mph at rated speed on the flat and go up a 1 in 4.6. Which as far as most operators are concerned is all you need for 32 tons.

"The Marathon with the TL12 engine and a 5.4 axle will do 66 mph and climb a 1 in 4.5." With a route involving a lot of motorway work, then from A to B, there would not be a great deal of difference in journey time. But off the motorways it could be a different story. As Ron put it: "i would to be hauling out of darl Derbyshire with a Buffalo-1 vehicle. This is where the f power of a Marathon-t vehicle comes in."

It comes down to defining operation that you're in drawing a compromise lin( the operation is payload sitive then a Buffalo, F8E Scania 81 is the best bet. If problem of drivers' hours is limiting factor then it may necessary to go Marath Scania 111, Bedford TM3/ etc. One point that Ron strong stressed in his corn ison between 32 and 38-to vehicles was the price paid the additional performan Again using Marathon and I falo to illustrate the point penalties are 1.2 tons £4,000.

The argument that a hi powered vehicle was likely tc operating at lower stress le: was treated with caution Ron. "It's very difficult to quantify when we're talking stresses. Theoretically reliability comes from lower stress levels and that is one thing that operators are looking for. Personally I would find it difficult to argue the extra ton payload against maintenance savings."

I queried the feasibility of a very high axle ratio used in conjunction with a road-speed governor. The Marathon is, in fact, offered with a 4.8 axle, which gives it a top speed of around 75 mph. "We've sold about three," said Ron, "but I agree there's a lot to be said for a road-speed governor in this case. '

"But in general, it would surprise me that, without bending speed limits too much, an operator would get much benefit on motorway operation from high power.

Transmission selection has often been a matter for argument in the past, especially with drivers. If the mail we receive at CM from drivers is anything to go by, they are not exactly over-enthusiastic for multispeed gearboxes. I put the point to Ron Armstrong.

"We seem to be wedded to

the multi-speed gearbox but, for other than motorway work, I don't particularly like it. Where I would advise an operator for it would be to give him flexibility in geography. And for motorway work you really do need the odd half gear."

Turning now to axle ratio selection, Ron suggested that for the Marathon the "middle" ratio of 5.4 is the best for most people. -The very high one I would avoid like the plague, and the only time I would insist on the 6.06 axle would be for hauling out of the Rhondda Valley."

With the Buffalo-type of vehicle there is not so much difference because of the lower torque. Here Ron would recommend the highest ratio that the !operator could get away with.

Tippers

If distances between tips are high then it can be useful to 'specify a tractive unit because of its power. But in general terms, around 230bhp. is the norm for an eight-wheeler. The big factor with tippers is maximum payload, especially in the sixwheeler category.

-With an eight-wheeler, you can have a route which is 200 miles on the motorway and two on-site, but those two miles have a lot to do with the vehicle selection," said Ron.

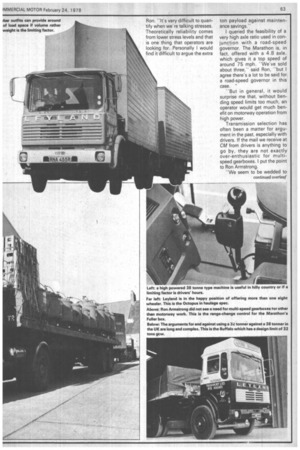

Leyland is in the happy position of offering more than one eight-wheeler chassis with the Routeman currently second only to Foden in this category. For the haulage operator a lightweight four-axle machine like the Octopus has a lot to recommend it in terms of pure payload capacity, but this argument has boomeranged on Leyland_ "The Octopus is seen as a haulage machine rather than a tipper. People tend to equate light weight with lack of strength, which is very unfair," he said.

For the choice of bogie suspension the Leyland view is that for good articulation in off-road conditions a two-spring bogie is necessary. Again Leyland offers a choice with the current split between two and four spring being about 50-50 on the sixwheelers with the two-spring being standard on the Octopus. The final word from Ron Armstrong on suspension: ''There is nothing that the four-spring can do that the two-spring can't."

Talking about rigid vehicle selection and in particular the single or double-drive argument put Ron in a tricky position as Leyland has standardised on double-drive! Bearing this in mind, he thought that the claimed weight saving between, say, a 6x4 and a 6x2 would not be so significant because usually the drive axle for the latter was beefed up. "But a 6x2 with a lifting axle is well worth considering if your type of operation means the vehicle is coming back empty."

The six-wheeler market has long been the preserve of the concrete mixer.

Here, for once, arriving at the optimum specification is relatively easy as you can get the length of the mixer and its centre of gravity from the manufacturer, from which it is possible to specify the correct wheelbase to suit — taking care to remember whether the mixer will have hydraulic drive or be powered by a donkey engine.

The problem, of course, is with general haulage, where the size, shape, weight of the load is often guesswork as far as the vehicle planning stage is concerned. So most six-wheelers end up at around 22 /24ft body length.

If you are likely to be involved in moving palletised loads then it is advisable to go for a body length which is a multiple of the pallet size plus enough to allow for sheeting. The standard size for a "Europallet" is 1m x 1.: (39.4 x 47.3in) so two pall side by side leave precious Ii left for wall side thickness i box van is used.

Because of the tipper/mi. dominance in the multi-a rigid sector, the multi-spe gearbox is advisable becat the total ratio spread is wl people are looking for wh includes the need for a very I first gear for soft going.

For road work, Ron Ar strong could not see any r reason why a nine-speed was necessary at 24 tons. 1 naturally aspirated L12 eng for example works well with six-speed box.

The reason the nine-spE Fuller 609 box is specified vs.

the 502 engine is purel) question of torque capaci "Normally," said Ron, "a speed box is quite satisfact, for a 24-ton general haulE machine."

For operators with dimir hing loads, the axle-load sit tion wants watching. Althot, never as sensitive in this area the 16-tonner, the six-vvheE tends to overload the frr whereas the eight-wheeler ter to do the same at the ba Whether or not this is a sensit area will decide whether o■, size tyres are needed.

• Graham Montgome