FLEET MODERNIZATION

Page 20

Page 21

Page 22

If you've noticed an error in this article please click here to report it so we can fix it.

WITH a towering new screening, crushing and loading plant as its background, an important fleet of Dodge lorries is being operated by W. J. Lavender, Ltd., from Littleton Lane, Shepperton, on the distribution of sand, gravel and all kinds of aggregate. Although the plant is not yet completed, it has already cost in the neighbourhood of 280,000 (including the cost of land). Further shore plant and ballast bins are to be erected, which will increase the output materially.

The business was founded about 17 years ago and the limited-liability company was formed in November, 1932. It has developed from a small undertaking, in which sand was loaded by hand, to one employing exclusively power appliances and having a staff of about 100 people.

A32 The material is pumped through an 8-in, pipe from the source of supply and is conveyed to the shore plant in barges propelled by water jets and possessing a remarkable degree of manceuvrability. It is then pumped to the screens for grading, all material of more than section being removed.

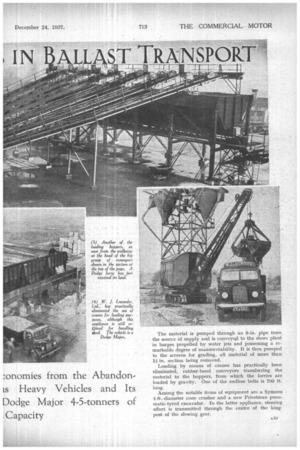

Loading by means of cranes has practically been eliminated, rubber-band conveyors transferring the material to the hoppers, from which the lorries are loaded by gravity. One of the endless belts is 700 ft. long. Among the notable items of equipment are a Symons 4-11.-diameter cone crusher and a new Priestraan pneumatic-tyred excavator. in the latter appliance, steering effort is transmitted through the centre of the king. post of the slowing gear. The transport fleet is at minimum strength at present, but is likely to be doubled by next spring. A few months ago the company disposed of its miscellaneous collection of heavy vehicles and purchased a fleet of 25 Dodge Major 4-5-ton lorries with B. and E. tipping gear.

Not only has this change effected an appreciable economy in costs, but greater convenience of operation has been secured. One notable advantage is the posses sion of a standard size of body (5 cubic yds.) throughout the fleet. This capacity represents a pay-load of about 6 tons, for which the Dodge Major is guaranteed.

Modernization of the fleet has been accompanied by a change of policy as regards maintenance. Previously, the company employed a large staff of fitters and carried out all its own maintenance work, but major operations, such as overhauls, are now entrusted to Messrs. Automotive Spares, of Ealing, who supplied the vehicles.

W. J. Lavender, Ltd., carries out only the normal servicing operations. Drivers are responsible, under supervision, for vehicle washing and greasing, for which they receive a sum in addition to their regular weekly wages and bonuses. The piecework system of paying drivers is not recognized by the company.

Special attention is paid to tyres, the pressures of which are checked daily. Firestone oversize equipment of 34-in. by 7-in. section is fitted and the policy of buying a first-class grade and taking care of it has, in the• concern's experience, proved to be the most economical.

In some quarters the practice of using low-priced tyres for such rough work as the haulage of sand and gravel, and replacing them at intervals of, say, 10,000-12,000 miles, is recommended. By purchasing good-quality equipment, however, W. J. Lavender, Ltd., is able to obtain mileages in excess of 20,000, despite the arduous conditions of operation.

This policy of buying good material is extended also to lubricating oil, which is changed every 2,000 miles. A specially close check is kept on the consumption of oil and petrol, a works official taking a daily reading from each lorry. This care. is well repaid, for the vehicles are returning a petrol-consumption figure equal to about 10 m.p.g.

The new Dodges have not been running sufficiently long fOr an annual average-mileage figure to be available, but it is expected that each machine will cover about 3.5,000 miles in 12 months. This is quite an appreciable figure in view of the fact that the C-licence vehicles operate within a radius of only 35-40 miles and the B-licence lorries within 25-60 miles.

Some of the factors influencing mileage are probably the fitting of a Servis recorder to each vehicle (thus

affording a check on delays, avoidable and otherwise), the provision of a high-speed loading plant, and the. use of a tipping gear that is rapid in operation.

The transport costing system provides for a weekly record of the expense of operating each machine, in addition to a weekly estimate of the cost of running the whole fleet. A monthly analysis of costs in respect of the fleet is also prepared. Costs are computed on the basis of the cubic yd.-mile, this being found to be the most convenient for quoting prices.

The policy of modernizing the fleet has thoroughly vindicated itself, in that the new Dodge vehicles are guying every satisfaction. The drivers appreciate their comfort and ease of handling, and the men's attitude is reflected in a complete absence of accidents.