The Work of THE RADIATOR

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

FROM experience of the hick of appreciation and, perhaps, understanding, of the work that is done by a radiator, no excuse is needed for summarizing its duties. It is intended to pass on the heat, absorbed by the water, from the cylinders to the air flowing through the radiator. Cool water then passes back to the jackets and the performance is repeated. Heat transmission relies on temperature difference and heat will, therefore, pass to the air only if the air be at a temperature which is lower than that of the water.

Heat absorbed by the water jackets of petrol engines varies from threequarters (in aero engines) to two and a half times that used in developing the actual power. One and a half is a normal figure for motor-vehicle work. An accompanying diagram shows a typical heat balance-sheet of a petrol engine. It will be noticed that 65 per cent, of heat is lost to exhaust gases

and water jackets. Ignition timing makes a considerable difference to the relative values of these two quantities. The radiator must, consequently, transfer to the air passing through it as much, or sometimes twice as much, heat as that taken to drive the vehicle along the road.

Factors Necessary for Efficient Operation.

There are three factors necessary to the efficient working of a radiator. First, the heat must be transferred from the water jackets to the radiator. Secondly, the metal surfaces between the water and the air passing through the radiator must be capable of transmitting the necessary amount of heat. Thirdly, there must be sufficient air passing through the radiator to absorb the heat without raising the air temperature too greatly, because in that case, the water would go back to the radiator still hot and would eventually boil.

Owing to the vital importance of these three factors they will be treated in detail. The first point is a question of water flow. The speed of water flow affects the dissipation of heat, mainly in two ways.

If the flow be sufficient, the water will, before it reaches boiling point, carry the heat to the radiator. When the water flow is insufficient, a largo difference in temperature is built up between the air and water, and the water will boil. This is accompanied by the formation of steam, which usually becomes trapped in the jacket heads. Finally, sufficient steam pressure is generated to force the water in the upper pipe into the radiator. This can cause surging in the water circuit and may result in loss of water.

B30

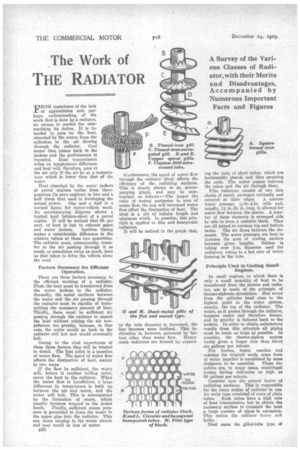

Furthermore, the speed of water flow through the radiator block affects the efficiency of the radiating surfaces. This is clearly shown in an accompanying graph, and may be summarized as follows :—The larger the ratio of wetted perimeter to area of water flow, the less will increased water flow affect the dissipation of heat. The ideal is a slit of infinite length and minimum width. In practice, this principle is applied to film and honeycomb radiators.

It will be noticed in the graph that, as the tube diameter is increased, the line becomes more inclined. This inclination is, however, governed by factors other than water flow. Honeycomb radiators are formed by expand ing the ends of short tubes, which are horizontally placed, and then sweating the ends. The water passes between the tubes and the air through them. Film radiators consist of two thin sheets of metal, arranged vertically and sweated at their edges. A narrow

water passage, wide and, usually, 11 in.-24 in. long, is allowed for water flow between the plates. A number of these elements is arranged side by side to form a radiator block. They are all joined to common top and bottom tanks. The air flows between the elements. The water passages are bent to iucrease the area of cooling surface between given lengths. Seldom is tubing over g-in. diameter used for radiators, owing to a hot core of water forming in the tube.

Principle Used in Cooling Small Engines.

In small engines, in which there is only a small quantity of heat to be transferred from the jackets and radiator, use is made of the principle of thermo-siphonie circulation. Hot water from the cylinder head rises to the highest point in the water system, namely, the top of the radiator. The water, as it passes through the radiator, becomes cooler and therefore denser, and by gravity is induced back to the jackets. In order to obtain satisfactory results from this principle all piping must be made as large as possible. In practice, the thermo-siphon system rarely gives a larger flow than about. six gallons per minute,

For lorries, buses, coaches and vehicles for tropical work, some form of water impeller is considered by some

designers to be essential. These impellers are, in many cases, centrifugal pumps having deliveries as high as 60 gallons per minute.

Consider now the second factor of radiating surfaces. This is responsible for the many makes of radiator in use. An early type consisted of rows of plain tubes. Such tubes have a high rate of heat transmission, but to obtain the necessary surface to transmit the heat a large number of pipes is necessary. This makes the radiator heavy and bulky.

Nest came the gilled-tube type at radiator. Owing to the increased surface per tube, fewer were neeelbd. The gills are made in various shapes.. They are often staxnped from old tins, there-, Lore, they are quite cheap.

Then there are film and honeycomb radiators. These sometimes present several disadvantages, such as leakage at

the end seams, silting up of the narrow water passages and, usually, a comparatively small area of cooling surface. Various means for increasing the area are being adopted, such as tins in the air spaces of the tubes. In cold weather, it is especially advisable to run the engine to warm the radiator before attempting to empty it of water. Capillary attraction of the water in the core is often sufficient to prevent a cold radiator from emptying itself.

The latest type of radiator tube on the market is believed to be that made by Clayton Dewandre and Co., Ltd., of Lincoln. In this design the tube itself differs from the gilled type, in that it has copper wire standing out radially, like the spokes of a wheel, instead of gills. The air, in passing over these wires, is efficiently combed and a large Proportion of it helps to cool the radiating surfaces. Proceeding now to the third factor, that of air flow, this cannot be too strongly emphasized. It should be obvious that if little air be flowing through a radiator, and a large horsepower has to be dissipated, the air temperature will quickly rise to the boiling point of water. The high temperature resulting under the bonnet is also detrimental to the lubricating oil.

When a Fan. is Necessary.

In England it is a usual practice, when a vehicle be small, to allow its speed to drive the air through the radiator, the flow of air generally proving sufficient to cool the engine without the aid of a fan. When the speed is lower and the size of the engine is greater, as in the case of many commercial vehicles, a fan is essential. An important point, commonly overlooked, is that the air will pass through the radiator only if it can afterwards escape from the bonnet.

A fundamental la* may here be emphasized. To dissipate 1 h.p., an air flow of about 120 cubic ft. per minute at normal temperature and pressure gives an air-temperature rise of

20 degrees Fehr. Large commercial vehicles may develop 100 b.h.p., and, if the engine be very cool, the ratio of heat to b.h.p. is equivalent to that of heat to water jackets. To prevent a rise in temperature of more than 20 degrees Fahr., 12,000 cubic ft. of air per minute are required. This fact raises the question of inotor-vehiele fans, about which there seem to be but little published data. However, few fans will, in normal practice, develop this air flow. A 20-in, diameter fan which is cowled and runs at engine speed, may cause a flow of 6,000 cubic ft. per minute at

about 2,500 r.p.tn. This means that an air-temperature rise of 40 degrees Fahr. is needed and the air flow becomes 6,000 cubic ft. per minute.

Now, a few words to all those who wish to make comparative trials of radiators. To carry out these on the road is nearly impossible. Wind conditions are so variable that only at low speeds, running with the wind, on the same day and on the same road, can any figures of interest be obtained. The only satisfactory test is on the bench,