New Denn tonner Fills tF

Page 46

Page 47

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

[11

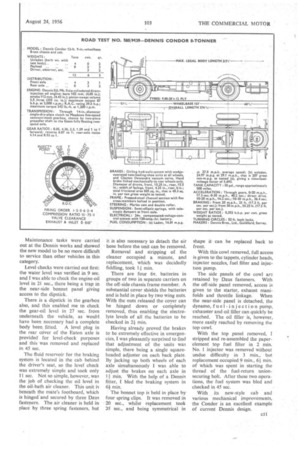

W1TH a new power unit, redesigned frame and braking system, and a — * new-style cab, the Dennis Condor 8-tonner is a more than worthy successor to the Dennis Centaur 71-ton chassis. The Condor, .which is announced today and will be shown to the public for the first time at Earls Court next month, was the subject of a recent road test.

Running at over 12 tons gross, it proved to be a powerful but economical 8-tonner, in which close attention has been paid to long life, safety and driver comfort.

The heart of the Condor is the latest version of the Dennis 5.5litre direct-injection oil engine. This ha-s been derived from the former power unit and has similar bore and stroke dimensions, but it has been greatly modified to give increased reliability and improved performance.

By altering the valve positions so that the inlet and exhaust ports are on opposite sides of the cylinder heads, the air and gas flows to and from the combustion chambers have been smoothed, with corresponding improvement in efficiency.

Prolonged gasket life has been assured by changing the positions of the cylinder-head studs: there are now studs between each bore, so that even gasket pressure is achieved throughout the length of the cylinder block. The engine has a dual exhaust-manifold system, with individual branches to each port, and twin exhaust pipes lead to a single silencer and tail pipe.

At the top of Woolmer Hill, where the gradient is 41, a smooth re-start was made, using low gear and high axle ratio. The hand brake held the Condor on this slope without assistance from the foot brake.

As used in the Condor, the engine is governed to 2,000 but the horizontal version fitted to the Pelican passenger chassis develops 92 b.h.p. at 2,200 r.p.m. The Condor engine has a pneumatic governor.

The engine is mounted as a unit with a Meadows 250 65 five-speed constant-mesh gearbox. On the test vehicle, which was the first production model, the gear ratios included an 8.05 to 1 low gear, as detailed in the data panel, but production chassis are to have a new gearbox with closer ratios.

These ratios are 633, 3,545, 2.53S., 1.656 and 1 to 1, with a reverse of 6.1 to I. Whilst the higher ratios are little changed, low and second gear are appreciably higher, which should give faster hill-climbing without drastically reducing maximumgradient ability.

Four-point mounting is used for the engine-gearbox unit. At the front of the cylinder block two Metalastik sandwichtype rubbers in compression and shear support the unit, • whilst at the rear there is a Metacone unit at each side of the bell housing. The effectiveness of this engine suspension combination was proved during the test, as the lack of engine vibration was most marked.

An Eaton 16,500 two-speed axle with electrically operated ratio change is fitted as standard, We drive tc which is taken from the gearbox through a two-piece propeller shaft with a rubber-mounted centre bearing and Hardy Spicer needle-roller joints, The frame has +-in. pressedsteel channel-section side members with 2+-in, flanges and a maxima) depth of 8* in. The five crossmembers, of top-hat section, are bolted.

Recent tests of Dennis vehicles have led me to expect good braking and in this respect the Condor is no xception. Girlimg wedge-operated units are employed at both axles and the total frictional area of 605 sq. in. should ensure long life and constant reliability. A Clayton Dewandre vacuum• servo is mounted inside the a,ff-side frame longitudinal forward A the centre-bearing cross-member.

Rubber Cab Mounting The cab underframe, which includes the bonnet panels, floor plates and wheel-arches, is mounted 3n rubber on the chassis frame at :hree points. The resulting cab sus Pension is most efficient: the degree Pf movement allowed is accentuated ly the relative movement between he driver's footboard and the pedals Ind steering coltunn, but it is limited )y two rubber snubbers on each side A. the single front mounting block.

A flat-tube radiator, with pressedwass top and bottom water tanks, as ipposed to the aluminium tanks weviously used, is bolted directly to he front dash panel and is thus elieved. of concentrated chassis

stresses. The cooling system is pressurized and an external filler cap is incorporated.

The standard cab is a composite assembly. This type of cab, which is already used on the Heron 3-ton chassis, is also to be used on the new Pax and Hefty models. For special applications, such as fuel-tanker chassis, an all-steel cab will be available. It has an identical appearance.

The cab is notable for the easy entry and exit provided by the wide forward-hinged doors and fully enclosed step. Ventilation is not so satisfactory, however, being restricted to winding windows in the doors. Opening windscreen panels are available as an optional extra, but swivelling vents in the doors and an extractor vent in the roof could advantageously be introduced as standard.

Other differences noted between the Condor and the Centaur include the use of longer springs, those at the front being 52 in. between eye centres, whilst the rear springs are 60 in. long. Telescopic dampers are fitted as standard at the front, so that suspension is satisfactory whether running laden or unladen.

Good Weight Distribution

The test chassis was not fitted with a body, but the stout timber and metal tray which supported the test weights was equivalent to the weight of a conventional platform body. A test load of 8 tons 2+ cwt. had been added, so that with driver and passenger aboard the gross running weight was 61 cwt, above that recommended by the makers. The weight distribution was good, being close to the ideal ratio of 1 to 2.

The first tests were conducted on The Peasmarsh, near Guildford, which is a reasonably quiet stretch of level road. Braking tests were made first and although the brakes had not been adjusted since the vehicle returned from 1,000 miles of testing at the Motor Inslustry Research Association's proving ground, satisfactory figures were produced.

Faint black marks on the road indicated that all the wheels were on the point of locking when making emergency stops. This is the condition under which maximum braking is achieved.

Although there was no discernible delay in the system, there was a marked difference in the average deceleration, as shown by the stopping distances and the maximum recorded by the Tapley meter, which was as high as 88 per cent. w hen braking from 20 m.p.h. Much of this difference, however, could be accounted for by forward pitching of the chassis when coming to rest.

Efficient Hand Brake

The effectiveness of the hand brake was shown by average Tapley meter readings of 33 per cent. when using it to halt the vehicle from 20 m.p.h. The lever is linked to the rear-axle compensator levers by a cable.

Several acceleration runs were made along the same stretch of road to decide the best combination of gear and axle ratios. The fastest times on the standing-start tests were made with high ratio engaged in all gears.

Conversely, the best direct-drive figures were obtained with low axle ratio engaged, although, theoretically, 30 m.p.h is not obtainable in top gear with the low axle ratio. The governor setting of the test vehicle may have been slightly higher than 2,000 r.p.m.

Two direct-drive acceleration tests were made with high axle ratio engaged, and the average figures obtained showed that from 10 m.p.h., 20 m.p.h. could be reached in 16.1 sec., and 30 m.p.h. in 51 sec. When cl 0 puffing away from below 10 m.p.h. in direct drive with either axle ratio engaged, the engine and transmission were commendably smooth, with no signs of excessive snatch or vibration.

Woolmer Hill, near Hazlemere, was used for the hill-climbing tests. This hill has an average gradient of 1 in 71, with a section of 1 in 4f, and its length is 550 yd. The climb was made in an ambient temperature of 68° F., and at the bottom of the hill the radiator temperature was recorded as 158° F.

The Condor• was climbing for 3 min 20 sec., of which time just over a minute was spent in low gear, high ratio, on th,e steep section. For the rest of the hill, second gear, high ratio, was sufficient to maintain a steady speed of just over 6 m.p.h.

Water temperature rose by only 12° F., which indicated that the engine was sufficiently well cooled for prolonged gradient working in high ambient temperatures, because the climb was completed without opening the thermostat fully.

A descent was then • made in neutral. The speed was kept down to 17 m.p.h. by application of the foot brake and a crash stop from 20 m.p.h. at the foot of the hill showed that although the pedal travel had increased only slightly, some fade was present. It must be remembered, however, that the brakes were not adjusted to their full efficiency. The drums were hot at the end of this test, but there was little smell of -burned facings and no smoking.

Returning to the 1 in 4f section, the vehicle was stopped and the hand brake held the chassis easily without recourse to the foot brake. A smooth re-start was then made in low gear with high axle ratio engaged. This performance was repeated several times and on no occasion was there any sign of smoke in the exhaust. The smoothness of the engine and transmission under full load was again notable.

Consumption tests were made along the Guildford-Horsham road, the starting point being at Shalford Church. The turn-round point was 10.3 miles up the road and the round trip was completed on 8.8 pints of fuel, which gave the satisfactory consumption rate of 16.81 m.p.g. for an average speed of 27.5 m.p.h.

These figures are particularly favourable in view of the undulating nature of the road, the amount of traffic encountered and the number of involuntary stops made because of road works and traffic conditions. The maximum speed attained during these runs was 30 m.p.h. and for the most part top gear and high axle ratio were used.

Having removed the test weights, but leaving the weight tray in position to represent the weight of a normal platform body, a second consumption run was made over the same course. There was little call for the indirect ratios on this occasion; by combining the laden and unladen figures, operators• should be able to estimate how the Condor would perform in their own service, depending upon the ratio of laden and unladen runs. With a large amount of unladen running, the overall average figure should be at least 19 m.p.g.

Pleasant to Drive

' The Condor is a pleasant vehicle to handle. The steering is reasonably light and satisfactorily accurate, and the 21-in.-diarneter steering wheel enables a good purchase to be obtained when manoeuvring in confined spaces. The pedals are all light in use, and the clutch, which is hydraulically operated, is particularly smooth.

Deep curved lights in the rear quarter panels ensure excellent allround visibility from the driving position, but I was disappointed to find that a near-side rear-view mirror was not fitted as standard, although twin electric windscreen wipers were. Engine noise was at all times reasonable, although the combustion note tends to be high-pitched. Maintenance tasks were carried out at the Dennis works and showed the new model to be no more difficult to service than other vehicles in this category.

Level checks were carried out first: the water level was verified in 9 sec. and I was able to check the engine-oil level in 21 sec., there being a trap in the near-side bonnet panel giving access to the dipstick.

There is a dipstick in the gearbox also, and this enabled me to check the gear-oil level in 27 sec. from underneath the vehicle, as would have been necessary had a complete body been fitted. A level plug in the rear cOver of the Eaton axle is provided for level-check purposes and this was removed and replaced in 45 sec.

The fluid reservoir for the braking system is located in the cab behind the driver's seat, so the level check was extremely simple and took only II sec. Not so simple, however, was the job of checking the oil level in the Oil-bath air cleaner. This unit is beneath the mate's footboard, which is hinged.and secured by three Dzus fasteners. The air cleaner is held in place by three spring fasteners, but

it is also necessary to detach the air hose before the unit can be removed. Removal and stripping of the cleaner occupied a minute, and eplacement, which was decidedly fiddling, took 11 min.

There are four 6y, batteries in groups of two in separate carriers on the off-side chassis frame member. A substantial cover shields the batteries and is held in place by two wing nuts. With the nuts released the cover can be hinged down or completely removed, thus enabling the electrolyte levels of all the batteries to be checked in 21 min.

Having already proved the brakes to be extremely effective in emergencies, I was pleasantly surprised to find that adjustment of the units was simple, there being a single squareheaded adjuster on each back plate. By jacking up both wheels of each axle Simultaneously I was able to adjust the brakes on each axle in 14 min. With the help of a Dennis fitter, I bled the braking system in 6i min.

The bonnet top is held in place by four spring clips. It was removed in 20 sec., whilst replacement took 25 sec., and being symmetrical in shape it can be replaced back to front.

With this cowl removed, full access is given to the tappets, cylinder heads, injector nozzles, fuel filter and injection pump.

The side panels of the cowl are retained by Dzus fasteners. With the off-side panel removed, access is given to the starter, exhaust manifolds and throttle linkage. When the near-side panel is detached, the dynamo, fuel-injection pump, exhauster and oil filler can quickly be reached. The oil filler is, however, more easily reached by removing the top cowl.

With the top panel removed, I stripped and re-assembled the paperelement top fuel filter in 2 min. No. 1 injector was removed without undue difficulty in 3 min., but replacement occupied 9 min., 61 min. of which was spent in starting the thread of the fuel-return union. securing bolt. After these two operations, the fuel system was bled and checked in 45 sec.

With its new-style cab and various mechanical improvements, the Condor is an excellent example of current Dennis design.