Battery-electric Marathon

Page 48

Page 49

Page 50

If you've noticed an error in this article please click here to report it so we can fix it.

UNTHI tried to exhaust the Manulectric battery electric 1-tonner, I boasted that I had never been beaten by any vehicle on test. Two days' work with this model showed that it well deserved the title of Marathon—and reminded me that I am no Theseus. It is distinctly a vehicle for the energetic roundsman, having a speed in keeping with a smart military pace, and its range is much greater than any retail salesman would care to walk.

The Manulectric is made by a concern which also operates vehicles of this type on milk delivery in the South Downs area. Practical experience is exemplified in the sound, simple design, and in the economical performance. Both the chassis and body are scientifically fabricated from light-alloy sheet and extrusions, so that there is less deadweight to be moved.

Great Stability Experience of operation among hills and on steeply cambered roads has established the condition that the centre of gravity should be low and the rear track wide. Therefore, the battery is underslung inside the frame immediately ahead of the rear wheels Study of operational requirements has proved the need for both rear wheels to be driven, so that full traction can be retained without wheelspin when ascending steep gradients in winter. The Electro Dynamic 2 h.p. motor is mounted atiove the axle and equipped with a centrifugal clutch to prevent overload.

From this clutch the drive is taken through a train of helical gears, affording double reduction, to the differential unit in the axle. Both the clutch and gears are enclosed in a light-alloy case.

The front wheel is steered by a tiller and can be turned at a right angle for manceurving in a small depot. By raising a safety catch the tiller can be turned through a full half-circle for reversing. The whole operation of the vehicle—steering, switching on the motor, applying the brakes and reversing the motor and brake gear—is controlled. by the tiller.

To lead the vehicle, a, pull on the tiller handle brings into action a two-stage switch and resistance, the second step being automatically con

trolled through a hydraulic dashpot. The brakes are applied and the power cut off when the control is moved towards the van body The operations are reversed when the driver is following the vehicle.

The layout of the contactors and braking linkage is simple, and any adjustment or replacement of the working parts can be done by raising tbe body, which is hinged at the rear. These components are carried on the top panel, forming part of the chassis frame, and there is a forward extension to the chassis alongside the front wheel to accommodate a goods box and delivery crate.

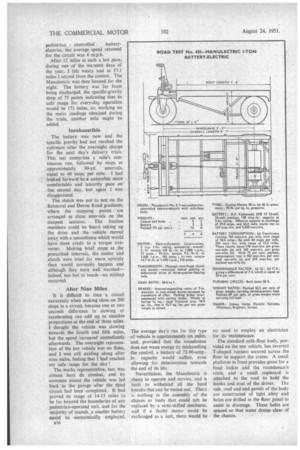

Without battery,, the chassis and body weighed 5i cwt., and in complete unladen form ready for the road the open dairy model tipped the scales at 9 cwt. After checking the battery specific gravity of all cells, the body was lowered and 15 cwt_ • 'of bagged sand, Irepresenting threequarters payload; added before starting the continuous run on " The Commercial Motor " standard course at Watford.

A 2 h.p. motor fitted to a lightweight; pedestrian-controlled vehicle enables hills to be climbed, with little reduction in speed. This was shown on the short journey to the weighbridge, which involves climbing a 'gradient at a railway siding, and min. was saved in, what is usually a 6f-min. run. Because of the clutch between the motor and wheels, there is a free-wheel action during over-running, and this is partly the reason for the economy of the Manuleatrie.

Apart from brief use of power to move off the weighbridge, the vehicle was free-wheeled down the incline at the start of the first circuit. There being no worm or spiral-bevel drive to the 'axle; the efficiency of the drive between the' motor and wheels is high, and the free-running

effort is correspondingly greater than with a coaventional drive.. The momentum of the vehiele isSUfficient to overrun the clutch on any slight incline, consequently the need for power on the hilly section of the Watford course was greatly reduced.

Feeling fresh at the start of the day, I kept pace with the vehicle to Balmoral Road, where the 1-in-15 gradient normally brings about a rapid fall in the speed of pedestriancontrolled battery-electrics. There was, however, relatively little slackening in the pace of the Manulectric and I was forced into a trot to catch up and take readings.

"Armchair" Braking The tiller is simple to operate, and is shaped at its end to fit' into the small of the back, so that {luring braking the operator leans back on, the handle. The brakes were effective, but I was not comfortable when walking in front of the vehicle on a steep decline. Each system has

its own good points, but my personal preference is for a tiller with a springloaded brake control. With this arrangement the brakes are applied immediately pressure on the lever is released.

The difficult section up Devon Road, which is the worst hill in the circuit, was covered without clutchslip, and at the top I called a halt to regain my breath. At the end of the first circuit, the vehicle had broken records for speed and economy.

In reducing the schedule time for

1-tonner by 6 mins., the average speed worked out to 31 m.p.h., and the consumption rate of 7.7 amp.-hrs. per mile indicated that, barring no failures on hills, I was in for a marathon effort to attain the maximum potential range of the vehicle.

There were no failures, and I kept walking, walking and walking, mile after mile, the pace accelerating at each circuit, until at 9.65 miles, which is beyond the capacity of most

pedestrian controlled battery electrics, the average speed returned for the circuit was 4 m.p.h.

After 12 miles at such a hot pace, during one of the warmest days of the year, I . felt weary and at 13.1 miles I retired from the contest. The Manulectric was then housed for the night. The battery was far from being discharged, the specific-gravity drop of 75 points indicating that its safe range for every-day operation would be 17/, miles, or, working on the meter readings obtained during the trials, another mile might be added.

inexhaustible The battery was new and the specific gravity had not reached the optimum after the overnight charge for the next day's delivery trials: This test comprises a mile's continuous run, followed by stops at • approximately 30-yd. intervals, equal to 60 stops per mile. I had looked forward to a somewhat more comfortable arid leisurely pace on the second day, but again I was disappointed.

The clutch was put to test on the Balmoral and Devon Road gradients, where the stopping points are arranged at close intervals on the steepest sections. The friction members could be heard taking up the drive and the vehicle moved away with a smoothness which would have done credit to a torque converter. Making brief stops at the prescribed intervals. the motor and clutch were tried far more severely than would normally happen and although they were well warmed— indeed, too hot to touch—no mishap occurred.

After Nine Miles It is difficult to time a circuit accurately when making close on 200 stops in a circuit, because one or two seconds difference in slowing or accelerating can add up to sizeable proportions at the end of three miles. I thought the vehicle was slowing towards the fourth and fifth miles, but the speed increased immediately afterwards. The overnight rejuvenation of the test vehicle was no fluke, and I was still striding along after nine miles, feeling that I had reached my safe range for the day !

The works representative, too, was almost hors de combat, and by common assent the vehicle was led back to the garage after the third circuit had been completed. It had proved its range of 14-15 miles to be far beyond the boundaries of any pedestrian-operated unit, and for the majority of rounds, a smaller battery could be economically employed. The average day's run for this type of vehicle is approximately six miles, and, provided that the roundsman does not waste energy by mishandling the control, a battery of 72-90-amp.hr. capacity would suffice, even allowing for deterioration towards the end of its life.

Nevertheless, the Manulectric is cheap to operate and service, and is built to withstand all the hard knocks that can be meted out. There is nothing in the assembly of the chassis or body that could not be replaced by a semi-skilled mechanic, and if a faulty motor could be exchanged as a unit, there would be no need to employ an electrician for its maintenance.

The standard milk-float body, provided on the test vehicle, has inverted T-shaped runners secured across the floor to support the crates. A small platform in front provides space for a food locker and the roundsman's crate, and a small cupboard is attached to the roof to hold the books and coat of the driver. The side, roof and end panels of the body are constructed of light alloy and holes are drilled in the floor panel to assist in drainage. These holes are spaced so that water drains clear of the chassis.