HINTS ON MAINTENANCE.

Page 28

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

363.—Removing Eccentric Bushes From Commer Car Chain Cases.

Wear sometimes occurs in the eccentric bushes at the back of the chain cases of the chain-driven Commer Car chassis. This is often neglected because it is wrongly thought necessary to dismantle the rear axle in order to fit new hushes. By adopting the following method they can be renewed with very little trouble.

Take off the outer half of the case and draw the sprocket shafts. Then remove the clips from the back of the eccentric and draw the studs marked (A) and (B) from the inner chain case. Well-slacken the stirrup bolts (C) and (D), and remove the pin in the brake-operating lever. The eccentric can then be tipped on the differential sleeve and the chain case pushed down, leaving it exposed so that the bush can be unbolted and the eccentric removed.

We would point out that it will be necessary slightly to spring the back half of the chain case in order to permit of its passing the end of the sleeves.

364.—Concerning the Retention of Oil on Tylor Engines.

The white metal oil-retaining split ring at the front end of the Tylor engine sometimes shears its dowel pin and consequently breaks. This results in loss of oil and occasionally causes ,great friction on the adjustment nut of the gland, which strips the thread in the timing gear cover.

To replace the parts in the ordinary way is an expensive job, but the fault can be remedied at a very much reduced cost in the following manner.

Commence by taking off the starting dog on the crankshaft, then the fan pulley and gland nut. Turn round the distance piece so that the plain part is nearest the timing wheel and in alignment with the recess for the oil retainer. This distance piece has oil grooves about half way along it. Now pack the recess for the oil retainer with felt and screw in the gland nut, which can be locked against the face of the timing cover in place of the oil retainer and dowel ordinarily employed.

B30

If the timing-cover thread is stripped, put the gland nut into position and drill and tap four i-in, holes, using the slots in the gland nut in order to mark the position. Then secure the nut by means of snaphead screws.

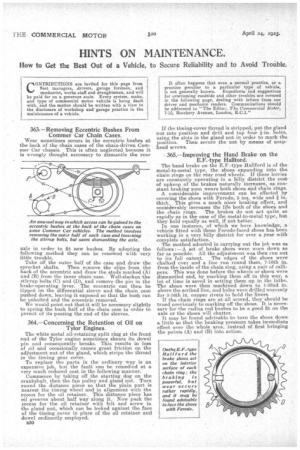

365.—Improving the Hand Brake on the E.F.-type Hallford.

The hand brake on the E. F.-type Hallford is of the metal-to-metal type, the shoes expanding into the chain rings on the tear road wheels. If these lorries are constantly operating in a hilly district the cost of upkeep of the brakes naturally increases,. as constant braking soon wears bath shoes and chain rings.

A considerable improvement can be effected by covering the shoes with Ferodo, 3 ins, wide and in. thick. This gives a much nicer braking effect, and considerably increases the life both of the shoes and the chain rings. The brakes do not act quite so rapidly as in the case of the metal-to-metal type, but they hold equally as well, if not better.

In one instance, of which we have knowledge, a vehicle fitted with these Ferodo-faced shoes has been working in a very hilly district for over a year with complete satisfaction.

The method adopted in carrying out the job was as follows :—A set of brake shoes were worn down so far as possible. All the adjustment was then run out to its full extent. The edges of the shoes were chalked over and a line run round them, 7-16th in. from the inside of the chain ring, using a pair of callipers. This was done before the wheels or shoes were dismantled and, by marking them off in this way, a lot of time is saved in setting them up in the lathe. The shoes were then machined down to 1-32nd in. above the scribed line, and holes were drilled unevenly for 3-16th in. copper rivets to hold the liners.

If the chain rings are at all scored, they should be trued previously to marking off the shoes. It is necessary for the radius rod bushes to be a good fit on the axle or the shoes will chatter.

It may be found advisable to turn the shoes down. a. little so that the braking pressure takes immediate effect over the whole area, instead of first bringing the points (A) and (B) into action.