A BRITISH

Page 58

Page 59

If you've noticed an error in this article please click here to report it so we can fix it.

Standard production

DIESEL BUS

for Municipal Service

A 50-mile Trial Run on Leeds Corporation's New CrossleyGardner Oil-driven Doubledeck Molorbus ANOtHER forward step in the progress of the compression-ignition engine is marked by the building of a 48-seater double-saloon bus with Crossley chassis and • Gardner sixcylindered heavy-eil engine for everyday service as one of the Leeds Corporation fleet. Mr. R. L. Horsfie/d, general manager of the transport department, and his chief engineer,..Mr. J. S. Broadbent, show commendable enterprise in their decision to try the Diesel, and they have received able co-operation from Crossley Motors, Ltd., and L. Gardner and Sons, Ltd., of Patrieroft, Manchester, as well as, in a consultant capacity; from Major W. U. Goddard, A.M.I.Mech.E., who is doing much in the North to push the oil engine.

The vehicle was put on the road last week and we had the opportunity for travelling 50 miles on one of its first journeys from Leeds to Manchester.

The Gorton works of Crossley Motors, Ltd.. has turned out a standard Condor chassis with an extension of only a few inches at the front end of the frame, two cross-bridges serving to support the Gardner power unit. A normal Crossley body for 48 passengers has been fitted. As both chassis and engine are standard in all respects. this probably constitutes the first all-British production job in the line of oil-driven passenger vehicles.

A Cold-starting Engine.

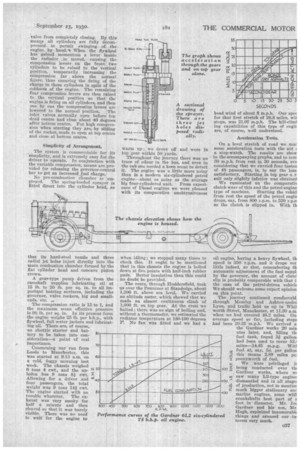

The Gardner 6L2-type six-eylindered high-speed oil engine is one of a series of such engines made with any number of cylinders, from one to six' and having a common bore of 4+ ins, and a common stroke of 6 ins. Details of its output and fuel consumption may be read from the accompanying graphs. Its speed is limited between 250 and 1,250 r.p.m., although considerably higher speeds are attained on the test bench.

The crankcase is in two parts, the lower half holding the seven bearings of the crankshaft ; the cylinders and water jackets are in two blocks of three, and the cylinder heads, which carry the exhaust and inlet valves and rockers, as well as the atomizers and special compression-control devices, are separate units, one for each cylinder. Aluminium pistons are used in cenjunction with forged-steel tubular connecting rods, these having ducts to carry lubricating oil under pressure to the small-ends.

The fuel-pump assembly is carried on the near side and comprises two banks of three pumps, each pump being operated by its own cam on a short camshaft and carrying a lever by which it can be put into or out of action by hand. A duplex chain drives the valve camshaft and this drives the short pump camshaft by helical gears. The fad reaches the pumps through a combined heater and strainer and passes thence to the atomizers, which have strainers.

The pumps are of the constant-stroke type, the commencement of injection being fixed at about 10 degrees before top dead centre, and the injection period being variable up to about 10 degrees after centre, by means of a helical slot in the rotatable sleeve surrounding the plunger. The maximum fuel-injection pressure is about 2,000 lb. per sq. in.

The governor is of the totally enclosed centrifugal kind and automatically controls the amount of fuel injected per stroke so as to snit the engine load.

Thus, the engine is, at all speeds, under the governor's conte,ol. This is extremely useful when manceuvring the vehicle, for it means that the driver need not use his accelerator pedal ; letting in the clutch increases the load and causes the governor to lengthen the injection period, increasing the quantity of fuel

supplied per stroke. Actuation of the accelerator increases the load on the governor spring--with the same result An essential and remarkable feature of the Gardner engine is that starting from cold is effected by hand without the aid of artificial heating of the combustion chamber by electric. coils or any such means. On each cylinder head is a lever normally pointing downwards, which, when raised to a horizontal Position, prevents the. inlet

valve from completely closing. By this means all cylinders. are fully decompressed to permit swinging..of -theengine, by hand.' When the flywheel has' gained momentum a lever beside the radiator Asmoved, causing the compression levers on the front two cylinders to be raised to the vertical position, temporarily increasing the compression far above the normal figure, 'thus ensuring the firing of the charge in those cylinders in spite of the coldness of the engine. The remaining four compression levers are then raised to the vertical position so that the engine is firing on all cylinders, and then one by one the compression levers are lowered to the normal position. The inlet valves normally open before top dead centre and close about 40 degrees after bottom centre. For high compression when starting they are, by sliding of the rocker, made to open at top centre and close at bottom centre.

Simplicity of Arrangement.

The system is commendable forl its simplicity, and is extremely easy foil the driver to operate. In conjunction With the variable compression, means are provided for releasing the governor-control bar to' getan increased fuel charge. No pre-combustion Chamber is em

ployed. The spring-loaded sprayer is fitted direct into the cylinder head, SO

that its hard-steel nozzle and three radial jet holes inject directly into the main combustion chamber formed by the flat cylinder head and concave piston crown.

A gear-type pump driven from the camshaft supplies lubricating oil at 15 lb. to 20 lb. per sq. in. to all important bearing surfaces, including the governor, valve rockers, big and smallends, etc. .4.

The compression ratio is 13 to 1, and the maximum mean effective pressure is 98 lb. per sq. in. In its present form the engine weighs 25 lb. per b.h.p., with flywheel, full water jackets and lubricat ing oil. There are, of course, no electric starter and bat tery to be taken into consideration—a point of real importance. 7 Concerning our run from Leeds to Manchester, this was started at 9.13 a.m. on a cold, foggy morning last week. The chassis weighed 6 tons 4 cwt., and the unladen bus 9 tons 81 cwt. I, Allowing for a driver and a' four passengers, the total weight was 9 tons 141 cwt. The engine started with no trouble whatever. The exhaust was very smoky for half a minute and then cleared so that it was barely visible. There was no need to wait for the engine to warm up ; we drove off and were in top gear within 50 yards.

Throughout the journey there was no trace of odour in the bus, and even in the cab one needed a keen scent to detect it. The engine was a little more noisy than is a modern six-cylindered petrol engine—about as noisy as the average big four-eylindered unit. From experience of Diesel engines we were pleased with its comparative unobtrusiveness when idling ; we stopped many times to check this. It ought to be mentioned that in this chassis the engine is bolted down at five points with half-inch rubber pads. Better insulation than this could no doubt be provided.

The route, through Huddersfield, took us over the Pennines at Standedge, about 1,200 ft. above sea level. We carried an altitude meter, which showed that we made an almost continuous climb of 1,000 ft. on top gear. At the crest we halted ; there was no sign of boiling and, without a thermometer, we estimated the radiator temperature at 180-190 degrees F. No fan was fitted and we had a head wind of about 8 m.p.h. Our spee for that first stretch of 28.8 miles, wit stops, was 21.07 m.p.h. The hill-climl log capabilities of this type of engit are, of course, well understood.

Acceleration Tests.

On a level stretch of road we mac some acceleration tests with the aid a stop-watch. The results are show in the accompanying graphs, and to rear 30 m.p.h. from rest in 30 seconds, eve considering that we carried four instea of 48 passengers' is, to say the lees satisfactory. Starting in top gear a IN suit only slightly inferior was obtained

We ruminated on the comparatis clutch wear of this and the petrol-engine type of machine. Starting the vehicl from rest the speed of the petrol engin drops, say, from 800 r.p.m. to 550 r.p.n as the clutch is slipped in. With th

oil engine, having a heavy flywheel, th speed is 350 r.p.m. and it drops ver, little indeed, so that, remembering th automatic adjustment of the fuel suppl by the governor, the amount of elutc. slip is probably comparable with that i. the case of the petrol-driven vehicle We should welcome some expert opinion on this point.

The journey continued comfortabI through Moseley and Ashton-undet Lyne, and traffic held us up in Whit worth Street, Delanchester, at 11.30 a.m. when we had covered 46.2 miles. Ou average speed so far, including stops had been 20.25 m.p.h. We arrived a the Gardner works 20 min utes later, and, filling th; fuel tank, found 31 gallon; had been used to cover 52: miles-14.45 m.p.g. Witt

▪ fuel at, say, 5d. per gallon D this means 2.89 miles pei pennyworth of fuel.

a: We were privileged it

• being conducted over tIn 500

Gardner works, where w( 1,3 saw many L2-type engine: 50 dismantled and in all stage:

• of production, not to mentiot

2 much bigger stationary an 00 marine engines, some witl crankshafts best part of s foot in diameter. Mr. Joe Gardner and his son, Mr. Hugh, explained innumerable things and aroused our intetest very much.