CALORIE CONTROL

Page 60

Page 62

Page 63

Page 64

Page 65

If you've noticed an error in this article please click here to report it so we can fix it.

Half of all the sugar consumed in Britain is home-grown.

Tim Maughan has been finding out how the bulker fleets handle the economic sweetener known as the sugar beet harvest.

Haulage is characterised by the need to transport as many goods as possible in the shortest possible time. Operators who serve British agriculture tend to do exactly that: dispatch HGVs to and fro in a brief seasonal flurry. In the flat expanses of East Anglia. however, hauliers haul sugar beet over a five-month period.

British Sugar supplies half the IJK's sugar. with the rest of it being imported from the African. Caribbean and Pacific sugar producing regions. by Tate & Lyle. East Anglian fields provide most British sugar beet. British Sugar has six factories, which are located in Shropshire.Suffolk.Norfolk.Nottinghamshire and North Yorkshire.There are also three dedicated packaging complexes.

British Sugar's brochure says: -Progress with root lifting is carefully monitored to meet factory intake requirements."This has a direct effect on the hauliers involved in carrying sugar beet.Take Bury St Edmunds-based StennettsTransport.The firm runs 25 HGVs, and uses the services of 25 subbies.11-ansport manager Charlie Stennett says: Sugar beet accounts for around 5% of our annual turnover, but in September and October that figure increases to 10%."

These figures are not large, but this is exactly the point: British Sugar demands its beet over a sustained period.There is little point in having vast quantities of II' beet piled up, only to see the crop deteriorate. The sugar beet harvest begins in September and continues until February.

A staggering 7,000 British farmers are contracted to provide beet to British Sugar. As a rule, says Stennett, farmers working in this sugar sector have tip-top equipment.This means that there are few problems getting a44-tonne balker loaded up with beet. His HGVs are soon back on the road and on their way to one of the two factories.

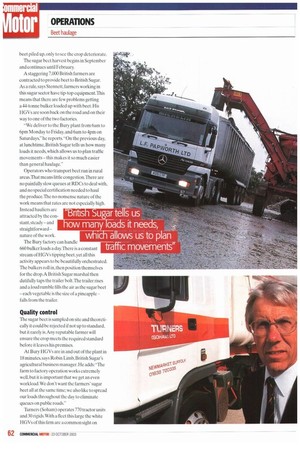

"We deliver to the Bury plant from 6am to 6prn Monday to Friday, and 6am to 4pm on Saturdays." he reports. "On the previous day, at lunchtime, British Sugar tells us how many loads it needs, which allows us to plan traffic movements — this makes it so much easier than general haulage."

Operators who transport beet run in rural areas.That means little congestion.There are no painfully slow queues at RDCs to deal with, and no special certification needed to haul the produce.The no-nonsense nature of the work means that rates are not especially high. Instead hauliers are attracted by the constantsteady — and straightforward — nature of the work.

The Bury factory can handle 660 bulker loads a day.There is a constant stream of HGVs tipping beet, yet all this activity appears to be beautifully orchestrated. The bulkers roll in. then position themselves for the drop. A British Sugar marshal then dutifully taps the trailer bolt.The trailer rises and a loud rumble fills the air as the sugar beet —each vegetable is the size of a pineapple — falls from the trailer.

Quality control

The sugar beet is sampled on site and theoretically it could be rejected if not up to standard, but it rarely is. Any reputable farmer will ensure the crop meets the required standard before it leaves his premises.

At Bury HGVs are in and out of the plant in 18 minutes, says Robin Limb, British Sugar's agricultural business manager. He adds: 'The farm to factory operation works extremely well, but it is important that we get an even workload. We don't want the farmers' sugar beet all at the same time; we also like to spread our loads throughout the day to eliminate queues on public roads."

Turners (Soham) operates 770 tractor units and 30 rigids. With a fleet this large the white HGVs of this lirrn are a common sight on British roads.There are Turners depots in Norwich. Felixstowe. Castleford and, of course Soham, Cambs. Director Franklin Turner works at the 22-acre Soham base.

There are 180 trucks operating from this depot,most of them reefers.The company mobilises four HGVs to take on sugar beet work.There are 12 bulker trailers. Each truck picks up the beet from farms and deposits it at either British Sugar's Wissington or Bury St Edmunds factory. in all, the company hauls 30 full bulker loads of beet a week.

Only large fleets have the capability to field capital equipment.only to see it lay dormant for long periods of the year.

Turners (Soham) is one of them.Turner says: a-sm=ar....ear.veen The sugar beet season starts in &I2 Septem ber.This year it ended in March, although it usually finishes in February. We use bulkers to carry the beet, which are parked up when the season ends.The units then revert to temperature-controlled work."

So is beet work really that simple? "The main complications are seasonal changes. Say it's January and it looks like there could be a frost. The sugar beet needs to be taken away from the farm, but the factory has a limited capacity — there may be no space and so the crop may be damaged."

In this case Turners may have to redirect its bulkers to another farm. If the ground is too dry the farmer will need to moisten the land in order to extract the beet, so an HGV collection will be delayed.

Like Stennett,Turner reports that there are no problems with queues at British Sugar factories. Interestingly, his firm plays a much bigger role in the latter stages of the supply chain:Turners' 44-tonne powder tankers collect processed sugar from British Sugar factories, and then deliver it to biscuit manufacturers. No less than 70 powder tankers are assigned to this task.

e no-nonsense nature o t e rates are not

No beet, no haulage

However, these tankers only run if farmers grow the sugar beet in the first place. David Papworth, owner of LF Papworth, farms 3,500 acres of Norfolk land. He grows a variety of crops, including 600 acres of sugar beet. Papworth is a member of a small agricultural consortium. the White Cross Sugar Beet Harvesting Syndicate, which consists of three farmers.

Papworth runs a 44-tonne Mercedes-Benz Actros and bulk tipper semi. Some ownaccount operators have trouble justifying an expensive HG V. but this is not a concern here.

"The Actros is used throughout the year," he reports.-We carry a lot of grain to mailings and mills.The grain is stored in silos which means there's work throughout the year."

Fewer than 10% of the truck's movements are generated by hire-and-reward work. On reflection, it's simply -not very rewarding!".

Papworth's profits are made from agriculture, not road transport.The White Cross Sugar Beet Harvesting Syndicate owns a 1260,000 sugar beet harvester. "The Actros delivers five loads a day to British Sugar's Cantley factory," he explains."These are all full loads, right through from September to January, sometimes even February."

The plant is 25 miles away from Papworth's land. Not far. but enough of a challenge when you bear in mind the narrow, twisty nature of the local roads."They are 25 bloody awful miles!" he says with feeling.

Imported beet in a bid to assist third-world farmers the EU allows sugar from former Commonwealth countries to he imported into the UK. which comes into Tate & Lyle's Silvertown factory. This forms the remaining 50% of our sugar consumption. lithe likes of Papworth produce too much sugar beet it must be exported. British Sugar.which is the sole processor ol home-grown sugar beet, produces 1.4 million tonnes of white sugar a year.The firm also produces 700,000 tonnes of animal feed from the sugar beet.

East Anglia's free-draining, well structured soils are perfect for growing this crop. so it is here that most of British sugar beet is farmed All the beet is grown under contract. Unlike most other agricultural sectors, this means that farmers are guaranteed a market and an agreed price for their crops.

Saying that, a farmer could rarely afford to own a 44-tonner that is only used during the beet season. Roger Crane, a member of the White Cross Sugar Beet Harvesting Syr clicate, farms 2,500 acres of Norfolk tan d;41 of these are devoted to growing beet.

Crane runs a Daf 95X.F with a bulkei trailer."We grow quite a lot of potatoe! and we deliver a lot of seed potatoes to other farmers," he says.

And the sugar beet? "Well, we get 60 tonnes of sugar beet per hectare (2.47 acres).The beet is delivered to British Sugar's Cantley factory,which is five miles due west of Great Yarmouth."

The Daf hauls 10,000 tonnes of beet a year; the syndicate transports 60,000 tonnes in a season."The truck does ix stand still for very long," says Crane. -There are some good hauliers aroun, hut our own truck is more cost effective. The Dal does not stand still very often, and it gives us flexibility. It does not make us a lot of money but it save; us a lot of money." •