Up to th inute on iandling

Page 66

Page 67

Page 69

Page 70

If you've noticed an error in this article please click here to report it so we can fix it.

.co

EXHIBITION REPORT

by R. D. Cater, AMInstBE

THE Coal Merchants' Federation Coal Handling Exhibition was opened at British Railways' Somers Town depot at St. Pancras, London, on Tuesday by Mr. Neil Carmichael MP, Joint Parliamentary Secretary, Ministry of Transport.

The highlights of the exhibition, which closed yesterday (Thursday), were the sophisticated and expensive cranes, grabs, shovels and conveyors, and the less expensive but equally complex automatic bagging and weighing machines. Every unit shown was, of course, intended either to reduce the labour involvement, which is by far the most expensive overhead of the trade, or make solid fuel more attractive to the customer.

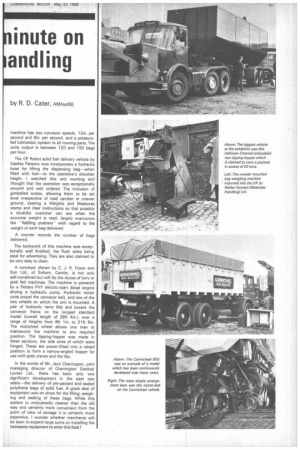

On the transport side all the familiar bulk vehicles were on show. Units from Charrold, occupying quite the largest section of the exhibition, included the biggest vehicle to be seen, a 32 tons g.v.w. non-tipping hopper semi-trailer hauled by an Atkinson powered by a Roils-Royce Eagle. This machine is reputed to carry a payload of smokeless fuel in excess of 20 tons.. Other vehicles on view were the well-proved Autobagger which the firm makes on a production line for stock, and a 21ft long Tippermatic-bodied Leyland Retriever. This machine had pneumatic discharge equipment and its body was fitted with a division board to enable split deliveries to be made or two grades of fuel to be carried.

Carmichael of Worcester showed its wellproved pneumatic discharge tipping-body mounted on an AEC Marshal. Although this vehicle bears the model number 800, it has in fact an 825 cu. ft. body. The discharge system is hydraulically driven from a pto pump and interposed between the Holmes Blower and the hydraulic motor driving it is a dogclutch enabling jammed rotors to be turned back for freeing. Another device on this machine which caught my eye was the extremely simple clutch for operating a load centralizing-auger at the back of the body. This is nothing more than a pair of vee pulleys and a slack belt which can be tensioned via a jockey wheel controlled by a lever. Simple but effective.

One of the newest to this country—loading devices at the show was a crawling, bagweighing conveyor shown by Walter Somers (Materials Handling). This equipment had a toothed conveyor belt driven by electric motor and was mounted on crawler tracks. Electric power enables the unit to be driven into a heap of fuel so that the conveyor belt is fed, At the receiving end of the unit electronic scales check off the amount of fuel loaded into bags and when a predetermined amount is reached the belt stops automatically. The

machine has two conveyor speeds, 12in. per second and 6in, per second, and a pressurefed lubrication system to all moving parts. The units output is between 120 and 150 bags per hour.

The CP Robot solid fuel delivery vehicle by Castles Parsons now incorporates a hydraulic hoist for lifting the dispensing bag—when filled with fuel—to the operative's shoulder height. I watched this unit working and thought that the operation was exceptionally smooth and well ordered, The inclusion of gimballed scales, allowing them to be set level irrespective of road camber or uneven ground, bearing a Weights and Measures stamp and clear instructions so that possibly a doubtful customer can see when the accurate weight is read, largely overcomes the "fiddling problem" with regard to the weight of each bag delivered.

A counter records the number of bags delivered.

The bodywork of this machine was exceptionally well finished, the flush sides being ideal for advertising. They are also claimed to be very easy to clean.

A conveyor shown by C. J. R. Fyson and Son Ltd., of Soham, Cambs, is not only self-contained but will do the duties of lorry or grab fed machines. The machine is powered by a Petters PH1 electric-start diesel engine driving a hydraulic pump. Hydraulic motor units propel the conveyor belt, and one of the two wheels on which the unit is mounted. A pair of hydraulic rams lifts and lowers the conveyor frame on the longest standard model (overall length of 39ft 4in.), over a range of heights from 8ft 1in. to 21ft gin. The motorized wheel allows one man to manoeuvre the machine to any required position. The tipping-hopper was made in three sections, the side ones of which were hinged. These are power-lifted into a raised position to form a narrow-angled hopper for use with grab cranes and the like.

In the words of Mr. Jack Charrington, joint managing director of Charrington Gardner Locket Ltd., there has been only one significant development in the past two years-the delivery of pre-packed and sealed polythene bags of solid fuel. A great deal of equipment was on show for the filling, weighing and sealing of these bags. While this system is undoubtedly cleaner than the old way and certainly more convenient from the point of view of storage it is certainly more expensive. I wonder whether merchants will be keen to expend large sums on installing the necessary equipment to enter this field ?

FROM a prestige point of view there is a considerable value to the manufacturer of the vehicle which wins the Grand Prix Louis Bollandard, the major award at the International Semaine du Car held in Nice every two years. As reported last week, Saviem won this Grand Prix this year and there was natural jubilation in the French camp at the result. But the Nice event includes much more than the "technical tests" for which the Louis Bollandard is awarded. There is also a rally section, a bodywork competition for six classes of p.s.v. and driving tests, and among the many prizes given there is one for the vehicle judged to have the best driving position (also won by the Saviem E7) and one for that considered best from a passenger's safety angle (won by an MAN).

The technical tests take up a complete day and detailed measurements are made of internal and external noise, acceleration performance and exhaust smoke emission. Suspension quality is also assessed and there is a brake test. Heavy rain on the day made necessary a modification to the brake tests —as well as making things miserable for spectators—and as a result they were less stringent than usual. Because of the rain there were very few spectators, but this was not in itself surprising for there are not normally very many. Points are assessed with complex electronic test equipment and there is little spectator value in watching vehicles being driven down a road, avoiding minor obstacles and stopping occasionally but giving no sign of how well or badly they are doing.

No indication is given of this even after the tests as individual marks are not published either for the separate tests or the total. And only the winner is announced —no placings are given—and there is no way of knowing the margin by which the winner beat the competition. It is therefore not possible to assess the technical superiority of the overall winner even though the top vehicle in each class for the individual tests is given and it is interesting that the Saviem E7 luxury coach that received the Louis Bollandard did not come at the top on any of the tests. The vehicle must therefore have been consistently good on the various checks.

Far more interesting for the spectators were the driving tests and the bodywork competition. The former took place at night and each competitor threads his way—in reverse over one part—through a complex course. As the total time taken appears to have as much importance as the avoidance of obstacles, most of the participants usually drive with a high degree of verve and in some cases with an apparent disregard of obstacles.

For the bodywork section all the vehicles are lined up on the "promenade" at Nice and fortunately the sun was out by this time. Even though the test results were not known, the biggest crowd was around the Saviem E7, Undoubtedly because this model was receiving its first public airing since its introduction in April.

In outward appearance the E7 is not remarkable and follows the general line of previous Saviem coaches and the current French styling with a slightly curved and simple front end, flat sides and vertical pillars. A major change for Saviem is the use of the rear-mounted engine. The power unit is an MAN six-cylinder in-line diesel with an output of 235 bhp gross and it is located vertically on the centre-line of the vehicle. The gearbox is a six-speed synchromesh unit and the suspension a combined leaf-spring and air system while the specification also includes a Telma retarder.

It was interesting at Nice to note the number of coaches having Telma retarders fitted particularly on high-powered coaches such as the E7 which are becoming increasingly popular for long-distance highspeed designs.

The body of the E7 is a semi-integral design with a space-frame type of chassis which allows full-width underfloor luggage lockers. These extend for almost the full distance between the front and rear axles for a capacity of 7.2 cu.metres (254 cult.). Overall length of the E7 is 12 metres (39ft 4in.) and the wheelbase is 6.23 metres (20ft 6in.). The model is designed for a maximum gross weight of 14.2 tons and the example at Nice had 53 luxury seats.

Another coach seen for the first time at Nice was the Currus CM which is based on the Citroen 350 chassis but with an MAN 96 bhp four-cylinder diesel mounted vertically at the rear by the bodybuilder. The gearbox is a five-speed synchromesh and three versions of the 25ft 4in.-long model were to be seen, two with 25 seats, one with 29.

At the 1967 Nice Sernaine du Car, Berliet introduced the Cruisair range of rearengined p.s.v. which, like the Saviem E7, has a combined leaf-spring-and-air suspension system. There has been little change to the design in the past two years except that the General Motors Detroit Diesel twostroke V6 was introduced very quietly as standard equipment on the Cruisair 2 and 3 last autumn. This engine which gives 200 bhp gross at 2,600 rpm has been adopted in place of the original Berliet unit to get greater power and the particular make and type was selected as one that would fit into the small space available.

Air conditioning equipment is getting to be very popular for luxury coaches in Europe and many at Nice had this feature. An interesting development was seen on a DAF with Van Rooyen 45-seat body. Completely automatic air conditioning to a new design by Acondi, a sister company of Van Rooyen was used, this being called Frivari_ The compressor for the air conditioning equipment is driven from the DAF 165 bhp gross turbocharged engine in the chassis through a Variomatic transmission as used on DAF cars. With the design, the compressor speed does not depend on the engine speed and I was told that with the engine running from 600 rpm and 2,500 rpm the compressor will run at between 1,950 and 2,200 rpm according to requirements. A big