An Electric Cuts Retail Delivery Time

Page 46

Page 47

Page 48

If you've noticed an error in this article please click here to report it so we can fix it.

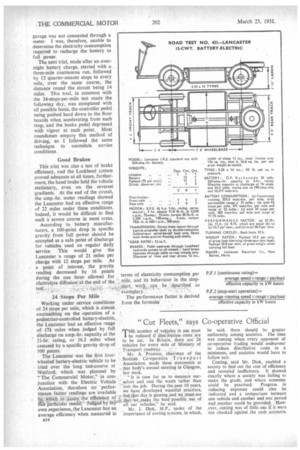

Lancaster 15-cwt. Battery-electric Performs Well When Tested on a Freezing Day .. Over "The Commercial Motor" Standard

Course in Hertfordshire.

By L. J.COTTO N, M.I.R.T.E.

ACCORDING to its specification, the Lancaster 10-15-cwt. battery-electric is.. equipped with a eti h.p. motor. This rating, judged by its performance on the hills in the test 7oute at Watford, appears an underestimate, because even the steepest inclines were tackled with zest and a good average speed maintained during each circuit.

There is nothing unusual in the Lancaster design; it has a conventional battery-electric frame, which is perhaps heavier than normal, with the batteries housed in two crates carried pannier fashion amidships between the wheels.

The motor, made by The Electrical Power Engineering Co., Ltd., of Birmingham; has a high torque and is connected to the rear axle through a La yrub propeller shaft, and double-reduction final drive.

The electro-magnetic contactor system employed is actuated by a controller incorporating a mechanically operated delayed action, which prevents power being fed to the motor too rapidly, thus safeguarding the transmission. Two resistances are connected in series in the first step, and one is cut out during the next stage. Following this, both resistances are connected in parallel, and in the final stage they are shortcircuited to give maximum speed.

The vehicle supplied for test was a standard forward-control model of 10-15-cwt. carrying capacity, and fitted with a closed van-type body. This body was devoid of wheel arches, the floorboards being arranged in sections to be removed to expose the batteries. The total capacity of the body is 200 cubic ft. al 2

After checking the unladen weight, the test instruments were fitted and a sandbag load added to b-ring the total payload up to 75 per cent. This is equivalent to the service condi(ions of a retail delivery vehicle, which leaves the depot fully laden and returns with trays or crates of empty bottles amounting to half payload.

Continuous Running Following the second excursion to the weighbridge,' I started the :ontinuous-run trial and recorded he average speed of 12-13 m.p.h., and balancing current on a level road In the outskirts of Watford. It was a cold day with an ambient of 29 degrees F., and compensation was required to the specific gravity readng of the electrolyte, because its :emperature was a mere 41 degrees F. The coldness of the day was reflected in the tractive effort required to overcome the churning )f the lubricant in the final drive, and the initial balancing current on he outward journey was 70 amps. Slight inclines on the approach to King's Langley made little effect on he road speed of the Lancaster, and he subsequent performance on the ills showed that for delivery work his vehicle could set a standard for nine-saving. Undoubtedly, for a nail unit, the motor has exceptional :argue.

The 540-yard climb up Langley Hill, with its 1-in-11 average gradient, brought the speed down to steady 7 m.p.h., and the current

flow registered from 176-194 amps. according to the severity of the incline. The time lost in scaling this rise was soon regained on the road into Whippendale Valley, but at all times road speed was restricted to

25 mph., whenever descending the hills.

Then followed the steep climb up the Onposite side of the valley involving a 110-yard timed section, where the Tapley meter recorded a 1-in-7i maximum gradient. This was climbed at a steady speed without any sign of overheating from the electrical system.

For the next mile the course is relatively level, but after this it again assumes the profile of a switchback railway, with moderate. gradients of 1-in-I0 to 1-in-15. The road surface in this section can, at the best, be described as second-class to poor, and driving over the ruts at 20-25 m.p.h. can be unpleasant even to the point of being unsafe. This was not so with the test vehicle, which, considering its rather short wheelbase, has a suspension system well suited to most conditions.

Readings on the Level: Readings were taken on the level during the return leg of the course, and at the Watford Junction sidings. which concluded one lap of 14.35 miles. This included the initial rim from the Eastern Electricity Board garage. As it requires at least an hour for the battery electrolyte fully to diffuse, the specific gravity readings were not taken at this point, but after stopping for the minimum period, the trials were resumed by attempting a further ;circuit..

The good average speed was again maintained, there being only a slight increase in the. time taken to scale Langley and Whippendale gradients. This trial reflected credit on the battery, because at the end of 28 miles, the amp.-hr. meters showed that it was past the 80 per cent. discharge point, when assessing the capacity at the 21-hr. rating, yet there was no marked. effect 'in the speed of the vehicle. Gravity 'readings taken one hour after completing 28 miles, showed a drop of 98 points, which is a Safe discharge to work to in everyday, service as advocated by battery manufacturers.

Unfortunately, no charger vvas supplied with the vehicle for these trials, and the unit installed at tha all

garage was not connected through a meter. I was, therefore, unable to determine the electricity consumption required to recharge the battery to full power.

The next trial, made after an overnight battery charge, started with a three-mile continuous run, followed by 12 quarter-minute stops to every mile, over the same course, the distance round the circuit being 14 miles. This trial, in common with the 24-stops-per-mile test made the following day, was completed with all possible haste, the controller pedal being pushed hard down to the floor boards when accelerating from each stop, and the brake pedal depressed with vigour at each point. Most roundsmen employ this method of driving, so I followed the same technique to assimilate service conditions.

Good Brakes This trial was also a test of brake efficiency, and the Lockheed system proved adequate at all times, furthermore, the hand brake held the vehicle stationary, even on the severest gradients. At the end of the circuit, the amp.-hr. meter readings showed the Lancaster had an effective range of 22 miles under these conditions. Indeed, it would be difficult to find such a severe course in most areas.

According to battery manufacturers. a 100-point drop in specific gravity from full power should be accepted as a safe point of discharge for vehicles used on regular daily service. This would give the Lancaster a range of 21 miles per charge with 12 stops per mile. As a point of interest, the gravity reading decreased by 16 points during the one hour allowed for electrolyte diffusion at the end of the test.

24 Stops Per Mile Working under service conditions of 24 stops per mile, which is almost encroaching on the operation of a pedestrian-controlled battery-electric, the Lancaster had an effective range of 171 miles when judged by full discharge on amp.-hr. capacity at the 2k-hr. rating, or 16.3 miles when assessed by a specific gravity drop of 100 points.

The Lancaster was the first fourwheeled battery-electric vehicle to be tried over the long test-course at Watford, which was planned by "The Commercial Motor," in conjunction with the Electric Vehicle Association, therefore no performance factor readings are available

which to assess the efficiency of ffii partidular modL lodged by be' own experience,,the Lancaster has an average efficiency when measured in

terms of electricity consumption per mile, and its behaviour in the stopstart wor_ can be described as exemplary.

The performance factor is derived from the formula

P,F.1 (continuous rating)=

average speed x range x payload effective capacity in kW hours P.F.2 (stop-start operation)= average running speed x range x payload effective capacity in kW hours