your truck deserv

Page 52

Page 53

Page 54

If you've noticed an error in this article please click here to report it so we can fix it.

DRIVER 'KNOW HOW

FROM THE driver's point of view the 2800 can be subdivided into two categories: the 248bhp DKTD model with the ZF gearbox and the 307bhp DKS version with the Fuller box.

The ZF is a six-speed constantmesh box with a splitter giving 12 forward ratios. The gearchange pattern is reversed with the low gears near the driver and the high gears away from him.

For moving from rest on the level with a gross weight of 32 tons, second low is usually more than adequate. It is not usually worth bothering with the splitter until fifth gear is reached when the sequence is fifth low, fifth high, sixth low to sixth high. On gradients, of course, the splitter can be used effectivey on all six gears to keep the engine in its optimum working range, but on level roads the torque spread of the DKTD makes this unnecessary in the lower gears.

Nor is it necessary to use all the gears in sequence. Depending on the road conditions—for example, if the truck has just reached the top of a hill—the driver can skip whole gears at his discretion. This technique can also be used coming down irough the hox when approachlig a junction.

)0UBLE IT!

he ZF AK 6-90 gearbox is a onstant-mesh design so double leclutching is definitely recom-tended for both up and downhanges. This technique extends he life of the gearbox and makes ure that the gear goes in the

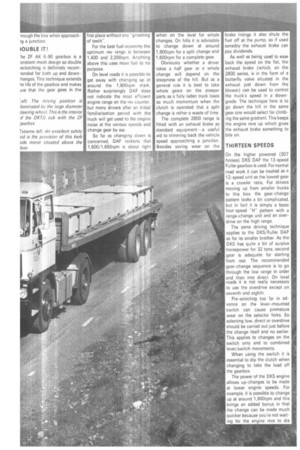

'_efto. The driving position is torninated by the large diameter ;leering wheel. This is the interior V the DK7 D cob with the ZF 7earbox.

Extreme left: An excellent safety ?id is the provision of this kerb tide mirror situated above the loot first place without any"gnashing of teeth".

For the best fuel economy the optimum rev range is between 1,400 and 2,200rpm. Anything above this uses more fuel to no purpose.

On level roads it is possible to get away with changing up at around the 1,900rpm mark. Rather surprisingly DAF does not indicate the most efficient engine range on the rev counter, but many drivers after an initial familiarisation period with the truck will get used to the engine noise at the various speeds and change gear by ear.

So far as changing down is concerned, DAF reckons that 1,600/1,650rpm is about right when on the level for whole changes. On hills it is advisable to change down at around 1,900rpm for a split change and 1,600rpm for a complete gear.

Obviously whether a driver takes a half gear or a whole change will depend on the steepness of the hill. But as a general rule it is best to take whole gears on the steeper parts as a fully laden truck loses so much momentum when the clutch is operated that a split change is rather a waste of time.

The complete 2800 range is fitted with an exhaust brake as standard equipment—a useful aid to trimming back the vehicle speed approaching a junction. Besides saving wear on the brake linings it also shuts the fuel off at the pump, so if used sensibly the exhaust brake can pay dividends.

As well as being used to ease back the speed on the flat, the exhaust brake (which, on the 2800 series, is in the form of a butterfly valve situated in the exhaust just down from the blower) can be used to control the truck's speed in a downgrade. The technique here is to go down the hill in the same gear one would select for climbing the same gradient. This keeps the engine revs up which gives the exhaust brake something to bite on.

THIRTEEN SPEEDS On the higher powered (307 horses) DKS DAF the 13-speed Fuller gearbox is used. For normal road work it can be treated as a 12-speed unit as the lowest gear is a crawler ratio. For drivers moving up from smaller trucks to this box, the gear-change pattern looks a bit complicated, but in fact it is simply a basic four-speed -I-1" pattern with a range-change unit and an overdrive on the high range.

The same driving technique applies to the DKS/Fuller DAF as for its smaller brother. As the DKS has quite a bit of surplus horsepower for 32 tons, second gear is adequate for starting from rest. The recommended gear-change sequence is to go through the low range in order and then into direct. On level roads it is not really necessary to use the overdrive except on seventh and eighth.

Pre-selecting too far in advance on the lever-mounted switch can cause premature wear on the selector forks. So selecting low, direct or overdrive should be carried out just before the change itself and no earlier. This applies to changes on the switch only and to combined lever/switch movements When using the switch it is essential to dip the clutch when changing to take the load off the gearbox.

The power of the DKS engine allows up-changes to be made at lower engine speeds. For example, it is possible to change up at around 1,900rpm and this brings an added bonus in that the change can be made much quicker because you're not waiting for the engine revs to die down quite so much.

For long gradients the OAF can be allowed to drop to around 1,600rpm when using the overdrive.

When using the splitter on the ZF gearbox it is essential to press the clutch pedal fully to operate the micro-switch which activates the change. With the ZF box a driver can be too clever and miss the gear, which means he is then running in neutral. Not realising this he can operate the exhaust brake when coming to a junction and stall the engine.

The ZF gearbox has the lower gears situated close to the driver rather than away from him. With the Fuller unit, the overdrive section works on the high range only. This, of course, stops the power-steering pump not a major disaster because of the large DAF steering wheel. But it is an incident which can be avoided in the first place with the correct driving technique. If you do find yourself in this situation, depress the clutchfully—which will engage the gear you wanted in the first place and then catch the engine.

This is not such a problem with the Fuller as a missed change like this makes a loud grating noise from the box so the driver should be in no doubt as to what has happened.

That deals with the actual technique of driving the 2800s but there are a few other bits of information which the driver could find useful.

The thermostatically controlled electro-magnetic fan can be brought into operation via an override switch on the instrument panel. This can be used if the fan fails to come into operation automatically, but it's also useful to switch it on a few minutes before stopping the engine. For example, if the driver knows he is stopping for lunch in a few minutes he can bring the fan into operation to avoid heat soak when the engine is switched off.

This valve situated behind the drivers seat can be used to fill the air tanks from the spare wheel to release the brakes in the event of starting difficulties and low air pressure. The truck can then be moved to bump start it when the spare wheel can be refilled from an equivalent valve on the other side of the cab. LOCK THE FAN If in an emergency the thermostatic drive and the switch both fail, the fan can be locked in mechanically. Two bolts on either side of the fan pulley can be slackened off and the two plates located under these bolts should then be pushed inwards until they engage with recesses in the other half of the fan clutch. The bolts should then be retightened, which leaves the fan with a permanent mechanical drive.

The excess fuel device on the 2800 series works only when the engine is cold. Once the engine is warm, the fuel delivery cannot be increased.

For economical driving it cannot be stressed often enough that checking the tyre pressures is essential. All DAFs are fitted with radials as standard, anyway, which is always claimed to improve the fuel consumption. But this can be a waste of time if the correct pressures aren't used.