Team spirit

Page 10

Page 11

Page 12

If you've noticed an error in this article please click here to report it so we can fix it.

From humble beginnings in 2005 Arcese UK has grown to be one of the haulage industry’s success stories, thanks, says its MD, to its loyal workforce

Words: Roger Brown

ARCESE UK is one of the success stories of the past few years. It now turns over more than £21m in this country alone, employs 140 staff and runs a leet of 100 vehicles.

The situation is all a far cry from late 2005 when the operation started with just ive people and one truck at its yard near Tilbury Docks in Essex.

Keith Luetchford, MD, recognises the vital support provided in those early days by its Italian parent – Arcese – that country’s largest privatelyowned transport irm.

However, he believes the UK company’s growth would not have been possible without the dedication and loyalty of the local team he has assembled.

“It was a case of one man and his dog at the beginning,” says Luetchford. “I left my previous job at Transmec, based in Thurrock and we moved into a small unit before eventually Arcese invested in this purpose-built cross dock warehouse, which was owned by DSV following its takeover of Fransmaas.

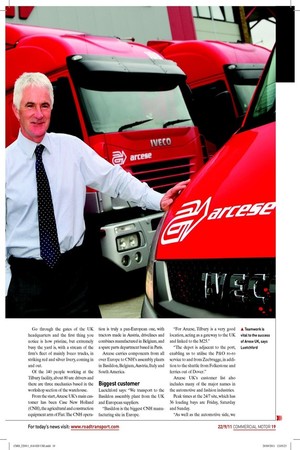

“A lot of the growth is down to the fantastic workforce here, and as a team we have managed to build up the operation into the second biggest for Arcese in Europe, after Italy.” Go through the gates of the UK headquarters and the irst thing you notice is how pristine, but extremely busy the yard is, with a stream of the irm’s leet of mainly Iveco trucks, in striking red and silver livery, coming in and out.

Of the 140 people working at the Tilbury facility, about 80 are drivers and there are three mechanics based in the workshop section of the warehouse.

From the start, Arcese UK’s main customer has been Case New Holland (CNH), the agricultural and construction equipment arm of Fiat. The CNH opera tion is truly a pan-European one, with tractors made in Austria, drivelines and combines manufactured in Belgium, and a spare parts department based in Paris.

Arcese carries components from all over Europe to CNH’s assembly plants in Basildon, Belgium, Austria, Italy and South America.

Biggest customer

Luetchford says: “We transport to the Basildon assembly plant from the UK and European suppliers.

“Basildon is the biggest CNH manufacturing site in Europe. “For Arcese, Tilbury is a very good location, acting as a gateway to the UK and linked to the M25.” “The depot is adjacent to the port, enabling us to utilise the P&O ro-ro service to and from Zeebrugge, in addition to the shuttle from Folkestone and ferries out of Dover.” Arcese UK’s customer list also includes many of the major names in the automotive and fashion industries.

Peak times at the 24/7 site, which has 36 loading bays are Friday, Saturday and Sunday.

“As well as the automotive side, we now carry high-proile fashion brands from France and Italy,” says Luetchford.

“Customer base diversiication is important and we have a marketing team for customer service and new business enquiries.” Arcese UK posted a solid set of results for the year to December 2010, with pre-tax proit rising to £208,879, from £182,939 the previous year. Turnover was £21.1m, up from £19.2m in 2009.

Consistent growth

Luetchford says: “2010 has seen an improvement in the market with more regular and consistent growth compared to 2008/09, but cashlow is still king.

“While our turnover has not improved substantially, we have replaced some unproitable high turnover business with smaller, more suitable work that its within our existing structure.

“It is important that we continue to manage and reduce cost as well as increase productivity.” In August 2010, Arcese UK won the contract from CNH to deliver spare parts to dealers in the UK, Scotland and Ireland, business that had been operated by haulier Through the Night (UK), which ceased trading that same month. Luetchford says the work has enabled the company to open a new branch ofice and warehouse in Rugby, which has allowed the company to increase its leet in the Midlands. “The opening of the Rugby branch has enabled us to reduce our vehicle operating costs for our northern customer base and improved our service, which in turn has led to further business opportunities,” says Luetchford.

“We hope to expand our night service for delivering spare parts to other customers.” Luetchford, who began his career in 1977 at a freight forwarder based in Dover, says that because of the nature of its work, the company’s proit and loss account will always be exposed to the value of the pound against the euro.

All Arcese clients are linked to a fuel surcharge and currency adjustment procedure. “We continually manage our business to ensure we have a balanced currency exposure between the euro and sterling to avoid the requirement to hedge against possible exchange rate losses.”

Future plans include building a twostorey, 16,000ft2 mezzanine loor in one section of the warehouse. Work is due to start on it next month. “The extra loor will give us more room to grow and we will consider making acquisitions if the time is right,” says Luetchford.

“However, our UK network is growing very rapidly, and is very strong now with the Rugby depot and our sub-depots in Exeter, Leeds, Manchester and Glasgow.

“Most vital to our success will be the continuing commitment, lexibility and dedication of our workforce.” ■