THE WEIG

Page 22

Page 23

Page 24

Page 26

If you've noticed an error in this article please click here to report it so we can fix it.

THEY WERE

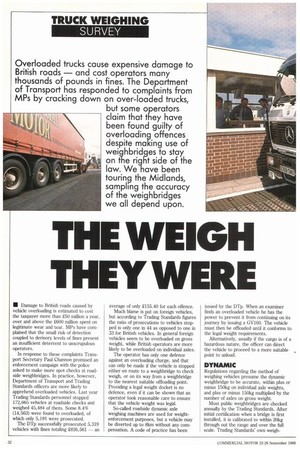

• Damage to British roads caused by vehicle overloading is estimated to cost the taxpayer more than £50 million a year, over and above the £600 million spent on legitimate wear and tear. MPs have complained that the small risk of detection coupled to derisory levels of fines present an insufficient deterrent to unscrupulous operators.

In response to these complaints Transport Secretary Paul Channon promised an enforcement campaign with the police asked to make more spot checks at roadside weighbridges. In practice, however, Department of Transport and Trading Standards officers are more likely to apprehend overloaded vehicles. Last year Trading Standards personnel stopped 172,64)5 vehicles at roadside checks and weighed 45,484 of them. Some 8.4% (14,563) were found to overloaded, of which only 5,191 were prosecuted.

The DTp successfully prosecuted 5,319 vehicles with fines totaling £826,561 — an average of only £155.40 for each offence.

Much blame is put on foreign vehicles, but according to Trading Standards figures the ratio of prosecutions to vehicles stopped is only one in 44 as opposed to one in 33 for British vehicles. In general foreign vehicles seem to be overloaded on gross weight, while British operators are more likely to be overloaded on individual axles.

The operator has only one defence against an overloading charge, and that can only be made if the vehicle is stopped either en route to a weighbridge to check weigh, or on its way from a weighbridge to the nearest suitable offloading point. Providing a legal weight docket is no defence, even if it can be shown that an operator took reasonable care to ensure that the vehicle weight was legal.

So-called roadside dynamic axle weighing machines are used for weightenforcement purposes, but a vehicle may be diverted up to 8km without any compensation. A code of practice has been issued by the DTp. When an examiner finds an overloaded vehicle he has the power to prevent it from continuing on its journey by issuing a GV160. The vehicle must then be offloaded until it conforms to the legal weight requirements.

Alternatively, usually if the cargo is of a hazardous nature, the officer can direct the vehicle to proceed to a more suitable point to unload.

DYNAMIC

Regulations regarding the method of weighing vehicles presume the dynamic weighbridge to be accurate, within plus or minus 150kg on individual axle weights, and plus or minus 150kg multiplied by the number of axles on gross weight.

Most public weighbridges are checked annually by the Trading Standards. After initial certification when a bridge is first installed, it is calibrated to within 20kg through out the range and over the full scale. 'Trading Standards' own weigh bridges are calibrated on a more regular basis, however.

There are a number of reasons why a weighbridge can give an incorrect reading. The most common of these is dirt and water accumulating, either on the plate or beneath it. Temperature or humidity has been known to effect the electronics, causing the readout to wander. Then there is just plain wear.

The more use a weighbridge receives the more often it needs to be calibrated if it is to remain accurate.

To find out just how confident operators and drivers should be in the accuracy of public weighbridges, we carried out a survey in the West Midlands.

Mercedes-Benz provided us with a 4x2 16.25 tractive unit to which we coupled our Crane Fruehauf tri-axle semi-trailer.

From the Commercial Motor Handbook on weighbridges we selected six sites at random, all on a route that we could complete in a day's driving. Before setting out we weighed the vehicle on MIRA's small 20-tonne weighbridge, which is used for our road test vehicles and we know to be calibrated regularly. It is a good site with level approach and exits, its only limitations being the size of the plate and its capacity.

SPLIT-WEIGH

For our survey we chose to make three separate check weighs of the front axle, the tractive unit as a whole, and the trailer bogie. Due to the upper limit of the MIRA bridge we had to split-weigh the three axles of the trailer.

Just a few kilometres west along the A5 from the MIRA proving grounds near Nuneaton we called in at Consolidated Tactor Services. The weighman was helpful and advised us that a separate charge of .1.50 would have to be made for each of the three weighs. With the exception of the Trading Standards weighbridge we adopted the same proceedure at each of the other public weighbridges. First the front axle was placed on the plate so the the drive axle was just clear. Then the tractive unit was placed close to the centre of the bridge; then the rear bogie was placed in a similar position.

The crs bridge measures 12m x 3m and has a 50-tonne capacity. It was clean and level and there was plenty of space to swing the vehicle round when we were ready to leave the site.

The Mercedes-Benz 1625 has a 3m wheelbase, so the front axle had to be placed right at the end of plate, although previous experience has taught us that more accurate readings can be achieved by using the centre of a bridge.

Our second stop was at the NCB coal mine at Arley where two bridges were in constant use. We chose the one with the shortest queue, used by loaded vehicles before leaving the pit.

The site was reasonably level, apart from a shallow road hump that had been constructed close to the leading edge of the weighing plate. Again it was a big plate, measuring 15m x 3m with a 50tonne capacity, but showed all the signs of its harsh environment.

The weighman seemed unused to providing a public weigh and took a few minutes to locate the necessary dockets. As at CTS this machine gave a printout, but here the charge was slightly less at 21.38 including VAT per weigh.

BUSINESS

While in the area we drove a few more kilometres along the road to another NCB mine at Kersley. We arrived at lunch time when business was slack and were able to drive straight onto the plate.

This time the weighman had to leave his desk to find the weighing dockets onto which he labouriously transcribed the readings by hand.

Although we had the fortune to pick a dry day this site was wet, which made this bridge look even dirtier than the previous one.

At Warwick we called in at the Trading Standards weighing station, where the three-section bridge, measuring 18mx3m overall, has a capacity of 60 tormes. After explaining to the weighman what we wanted, he advised us how he needed the vehicle to be placed and told us to turn off the engine and release the park brake.

With the drive axle positioned on the narrow centre plate all three weights were given without having to move the vehicle further, for a total cost of 24.40. To obtain the weight of the tractive unit the separate weights of the two axles were simply added together.

To demonstrate the machine's consistency the weighman also provided a total weigh which was within 20kg of the combined weights.

At Ryton the Warwickshire County Council weighman needed to be persuaded to provide us with the three seperate figures we required. It is a busy wastedisposal site and a queue of impatient OP' drivers soon formed up as the operator made heavy weather of filling in the forms. In true bureaucratic manner the more they hooted the longer he took. The charge of 26.40 could not be paid in cash: instead he billed. Commercial Motor.

The approach to the bridge is level and clean but there is no through route to the exit so we had to drive on into the site before finding a side track in which to reverse and turn around.

At Rugby the WCC's 12mx3m 40-tonne public weighbridge is situated on an incline but it was clean and easily accessible. The charge was only 24.40, but again it had to be paid by post.

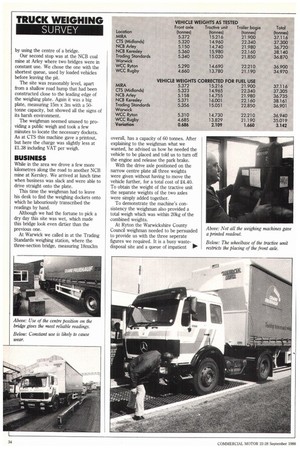

In the table we have listed the sites as we visited them in order with weights obtained at each. We have included corrected weights, assuming a fuel consumption of 40 litres/100km (7mpg).

It can be seen that for the front axle there is a wide divergence, from 4.685 to 5.371 tonnes — 686kg between the heaviest and lightest readings.

For the tractive unit as a whole we recorded a range of 2.109 tonnes and for the trailer bogie 1.660 tonnes.

SEMBLANCE

Nowhere among the weights obtained is there a semblance of consistentcy, so we do not know if any of the weighbrides provided a correct roading.

According to the reading given at Rugby the vehicle could have returned to base to add a further three tonnes, while if the NCB Keresly figures are to be believed the vehicle was already overweight.

There is no reason to suppose that our experience is not typical of the accuracy that is to be expected by hauliers throughout the country.

The public weighbridge system is inadequate for the needs of the road haulage industry and it must be questioned how they can be legal for trade.

As we pointed out, due diligence is not accepted as grounds for an aquittal if a vehicle is found to be overloaded. After seeing these results we are left wondering just what the haulier is expected to do to ensure he is running legally.

by Bill Brock