QUICK AND SMOOTH Off the Mark

Page 46

Page 47

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

By John F. Moon, A.A, SINCE the Atkinson PD.746 double-decker bus chassis was introduced in August, 1954, an alternative transmission specification has been drawn up. Instead of the five-speed constant-mesh gearbox for which the chassis was -originally designed, a direct-acting sernkautomatie Unit can now be supplied as optional equipment.

The semi-automatic gearbox is the Self-Changing Gears RV28 electro-hydraulic unit and,.as.fitted AO the-Atkinson chassis tested; it was used in conjunction with the gearbox maker's Fluid-Friction coupling. This consists of a centrifugally actuated shoe-type friction clutch combined with a small fluid coupling,_ the whole assembly being no larger

than the normal 18-in.-diameter fluid coupling Which has been in use for many years.

The advantage of the Fluid-Friction coupling is that, whilst still giving a smooth, shock-free take-up of drive when starting from rest, the frictional section takes over the drive between engine and gearbox at about 850 engine r.p.m. Thus, the slip which normally occurs at high speed with a hydraulic coupling is abolished, greater transmission efficiency resulting. A further advantage is that full engine braking is retained down to a low road speed and the engine can be restarted by towing or coasting, these not being possible with an ordinary centrifugal clutch.

Self-contained Gearbox Because the gearbox is hydraulically actuated, it is self-contained, unlike the air-operated version, which relies on an engine-driven compressor to power the brake-band pistons. Thus, as in the case of the test vehicle, which had a vacuum servo, the hydraulic box can be used in a chassis which has no air-pressure system.

Hydraulic power is provided by a gear-type pump inside the gearbox, oil being drawn from the sump of the box. The control valves are electrically operated, a small five-way finger-tip switch being mounted on the left of the steering, column, as with the electro-pneumatic layout.

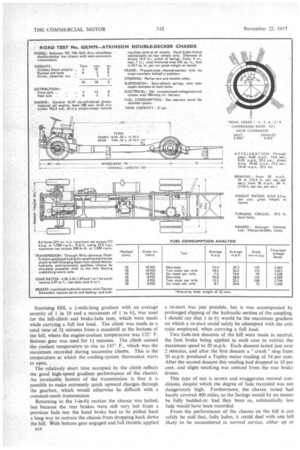

As shown by the results obtained during the test, this transmission gives good acceleration and . promotes economical non-stop running, although when making six

n12

• stops per mile, as on ,heavy town operation, the high acceleration rate and greater use of the fluid section of the coupling cause the fuel consumption rate to be slightly higher than average. The transmission is smooth in operation and even when making full-throttle changes there is

no shock transference to the chassis, because of the continuous traction effect given by the controlled gearbox• brake-band actuation 'rates.

The chassis specification itself has not been changed since its original introduction,the Gardner 6LW oil engine and Kirkstall axles being retained. The braking system is :unusual for a bus chassis, in that a Lockheed hydraulic system is employed, boost being provided by a large -• Clayton Dewandre vacuum servo. Air-pressure dr triplevacuum-servo brakes can be fitted as optional equipment.

The full-length frame side members are not dropped aft of the rear axle, as the chassis has been designed primarily for a central-entrance double-decker. The frame can be cut behind the rear-spring rear hanger brackets, however, to allow the use of a dropped extension. The side members are of 1-in, pressed-steel channel, with a maximumdepth of 11 in. and 3-in. flanges.

There were no body panels at all, other than a radiator grille, on the test chassis and a load totalling 64 tons had been mounted. Assuming a body weight of 24 tons, the vehicle was carrying the equivalent of 56 passengers, plus driver and conductor. Half-load tests were made with an equivalent load of 24 passengers. The trials were con. ducted in the Coventry area.

Braking and acceleration tests were made first while the roads were still dry, a level stretch adjacent to f3aginton Aerodrome being used. Full-pressure stops were • made from both 20.m.p.h. and 30 m.p.h. and a lag in the system of the order of 25 per cent. was noticed on each occasion.

Nevertheless, the figures obtained were reasonably satis factory for a double-decker chassis, high maximum retardation rates being likely to cause injury to standing passengers under emergency conditions. The hand brake, when applied from 20 m.p.h., produced average maximum Tapley meter readings of 28 per cent., which is good for a fully laden double-decker.

Standing-start acceleration tests were made using all four gears and good times were recorded. The throttle was left fully open during each change, but there was no harshness in the take-up of drive. Similarly, creditable direct-drive figures were obtained, the engine having good torque characteristics at low speed. No transmission roughness was observed when pulling away in top gear from 9 m.p.h.

A four-mile out-and-return undulating stretch of the busy Coventry by-pass was used for the fuel-consumption tests. It has a dual carriageway and roundabouts were used for turning without having to stop.

Town and Country Three runs were made when carrying full test loads. The first, during which stops were made, is representative of the conditions likely to be encountered in coaching and occasionally on bus operation in isolated country districts. The two-stops-per-mile tests gave a figure more representative of normal country service, whilst the six-stops-permile result gives an average figure for stage-carriage operation in congested-urban areas.

As the results in the analysis panel show, the Atkinson gives economy above average when running non-stop, whilst the slightly heavier consumption rates when making stops are compensated for by the higher average speeds.

A similar ratio of fuel-consumption figures resulted from the part-load runs, which were made over the same course. Both these series of tests were made in driving rain. -The ambient temperature was below 50° F., so it is probable that better figures would have resulted had the engine been cowled to give higher engine temperatures.

Sunrising Hill, a 1-mile-long gradient with an average severity of 1 in 10 and a maximum of 1 in 64, was used for the hill-climb and brake-fade tests, which were made while carrying a full test load. The climb was made in a total time of 31 minutes from a standstill at the bottom of the hill, where the engine-coolant temperature was 132° F. Bottom gear was used for 11 minutes. The climb caused the coolant temperature to rise to 147° F., which was the maximum recorded during successive climbs. This is the temperature at which the cooling-system thermostat starts to open.

The relatively short time occupied by the climb reflects the good high-speed gradient performance of the chassis. An invaluable feature of the transmission is that it is possible to make extremely quick upward changes through the gearbox, which would otherwise be difficult with a constant-mesh transmission.

Returning to the I-in-61 section the chassis was halted, but because the rear brakes were still very hot from a previous fade test the hand brake had to be pulled back a long way to restrain the chassis from dropping back down the hill. With bottom gear engaged and full throttle applied a re-start was just possible, but it was accompanied by prolonged slipping of the hydraulic section of the coupling. I should say that 1 in 61 would be the maximum gradient on which a re-start could safely be attempted with the axle ratio employed, when carrying a full load.

Two fade-test descents of the hill were made in neutral, the foot brake being applied in each case to restrict the maximum speed to 20 m.p.h. Each descent lasted just over 2 minutes, and after the first descent a " crash " stop from 20 m.p.h. produced a Tapley meter reading of 54 per cent. After the second descent this reading had dropped to 43 per cent. and slight smoking was noticed from the rear brake drums.

This type of test is severe and exaggerates normal conditions, despite which the degree of fade recorded was not dangerously high. Furthermore, the chassis tested had barely covered 400 miles. so the facings would by no means be fully bedded-in: had they been so, substantially less fade would have been recorded.

From the performance of the chassis on the hill it can safely be said that, fully laden, it could deal with any hill likely to be encountered in normal service, either up or down, in perfect safety. Fade is certainly not likely to prove any great problem under ordinary conditions, because even after the six-stops-per-mile run there was little evidence of fade having taken place.

The chassis is pleasant to handle (even when the driver is exposed to unfavourable elements) and the steering, although not light, does not become tiring at normal speeds. It is certainly light to drive when the semi-automatic transmission is fitted, as gear changing involves negligible physical effort, being restricted to movement of a 2-in.-long lever.

Normal retardation rates when carrying a full load can be obtained with -relatively light pedal pressure of below 100 lb., and the pedal travel is long enough to allow sensitive control when running unladen.

No maintenance tests were attempted on the vehicle-this would have been pointless in the absence of bodywork. The chassis has obviously been laid out with the object of simplifying maintenance. Brake adjustment, for instance, is straightforward and the lost-motion scissors-type linkage at the rear brakes helps to reduce adjustment time.