AN AUTOMATIC VARIABLE GEAR.

Page 198

If you've noticed an error in this article please click here to report it so we can fix it.

A Resume of Recently Published Patent Specifications.

T"automatic variable gear still occupies the attention of inventors, although very little success has been achieved up to the present in this direction. The specification of Rene • F. M. Fontain, of Paris, No. 270,699, describes a gear in which power is transmitted along a shaft from the engine to a spider (B), which -carries planetary gears working between a pinion on the driven shaft and an internally toothed ring (C) attached to a member which if allowed to revolve freely, would do so, and no power would be transmitted to the pinion on the driven shaft, whereas, if the member (0) were attached to the engine shaft, all would revolve at the same speed, and this would produce what is known to-day as top gear. We will now suppose that the member (C) were allowed to slip, or, in other words, to revolve backwards in relation to the engine shaft, and the esuiting drop in shaft speed would be entirely governed by the amount of slip or backward inovement of the mem

ber (C) in relation to the engine shaft.

The member (C) is provided with a sleeve attached to a worm wheel into which two worms engage. These worms are mounted in a carrier which can revolve on the engine shaft, but its rotary movement in relation to that shaft is governed by means of an arrangement of skewed bevel gears, the speed of which is governed by an edge wheel and a friction disc, the edge wheel being made to slide along its hollow shaft by means of tim screwed shaft shown.

The relative movement of this screwed shaft with the hollow shaft is gay-rned by a bevelled friction wheel, which can be made to revolve in either direction by its being brought in contact with two bevelled faces of the hollow sleeve which surrounds the engine shaft. This sleeve is driven with the engine shaft, and its sliding movement is determined by means of the governor shown. When the hollow sleeve is centrally situated in relation to the friction bevel wheel no motion is transmitted to the latter consequently, the speed remains constant, but, when the governor comes into action, a movement along the shaft of the hollow sleeve takes place, and rotary motion then takes place in the screwed shaft and the ratio of the engine shaft with that of the driven shat is altered.

E42 We have before seen intermediate gears that were allowed to slip backwards by means of worm and worm wheel governed by a friction disc, but the controlling of such a disc by means of a governor appears to be novel.

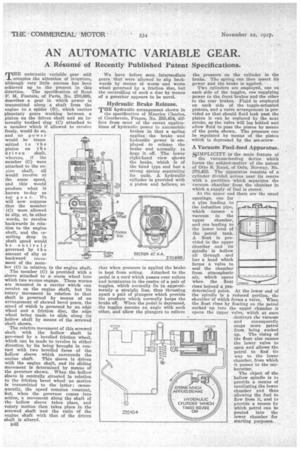

Hydraulic Brake Release. Trm hydraulic arrangement shown in the specification of Maurice Charles,

of Courbevoie, France, No. 255,454, dif fers from most of the reeent applica tions of hydraulic power to automobile brakes in that a spring aPPlies the brake and hydraulic power is employed to release the brake and normally to keep it off. The lower right-hand view shows the brake, which is of the band type and has a strong spring separating its ends. A hydraulic cylinder is provided with a piston and bellows, so that when pressure is applied the brake is kept from acting. Attached to the Pedal is a cord which passes over rollers and terminates in the centre of a pair of toggles, which normally lie in approximately a straight line, thus thrusting apart a pair of plungers which provide the praAure which normally keeps the brake off. When the pedal is depressed, the toggles assume an angle with each other, and allow the plungers to relieve the pressure on the cylinder in the brake. The spring can then assert its power and the brake is applied.

Two cylinders are employed, one on each side of the toggles, one supplying power to the front brakes and the other to the rear brakes. Fluid is employed on each side of the toggle-actuated pistons, and a valve arrangement is provided so that should fluid leak past the piston it can be replaced by the next stroke, as the valve will lag behind and allow fluid to pass the piston by means of the ports shown. The pressure can be regulated by means of the piston which is depressed by the set-screw

A Vacuum Fuel-feed Apparatus.

SIMPLICITY ig the main feature of the vacuum-feeding device which forms the subject-matter of the patent of Otto S. Ruud, of Oslo, Norway, No. 278,452. The apparatus consists of a cylinder divided across near its centre with a partition which separates the vacuum chamber from the chamber in which a supply of fuel is stored.

At the upper end there are the usual openings, one for a pipe leading to the induction pipe, which causes a vacuum in the upper chamber, and one leading to the lower level of the petrol tank. A float is provided in the upper chamber and its spindle is all throughlhrousgh d has a head which forms a valve to seal the chamber from atmospheric air, which opens when the float rises beyond a predetermined point. At the lower end of the spindle is a reduced portion, the shoulder of which forms a valve. When the float rises by floating on the petrol sucked up into the upper chamber it opens the upper valve, which at once destroys the vacuum and consequently stops more petrol from being sucked up. The rising of the float also causes the lower valve to open and allows the petrol to find its way to the lower chamber, from which it passes to the carburetter.

The object of the hollow spindle is to provide a means of ventilating.the lower chamber and thus allowing the fuel to flow from it, and to provide a means by which petrol can be poured into the lower chamber for starting purposes.