A New-type Rotary Motor Plough.

Page 128

Page 129

If you've noticed an error in this article please click here to report it so we can fix it.

1 TARIOUS types of rotary plough V have been devised from time to time, but none has been successful in producing the necessary tilth required; they have either not cultivated to a sufficient depth or have brought too much of the subsoil to the surface. A new type, however, has just been built by John Fowler and Co., Ltd., Leeds, manufactured under Storey's patents, which produces a proper finished tilth in one operation, eliminating ploughing, cross-ploughing, discing, harrowing and other operations. It has been constructed for working on sugar plantations in Cuba, where the land has to be cultivated as quickly as possible in the cane-planting season. An experimental machine has been tested for two seasons in Cuba, and the results have proved excellent.

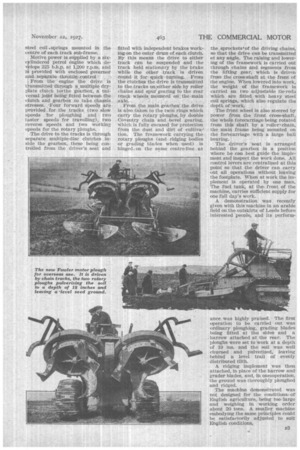

The principal feature of the machine is two rings of ploughs rotating on approximately vertical axes at the rear of the main frame, being carried on a hinged framework which can be raised or lowered as required. These' two ringsof rotating ploughs revolve outwards from the centre and cover a total width of 10 ft., each ring being arranged to carry either three or six bodies, according to the requirements of the sod. The working angle is arranged so that the rear portion of the rings is closer to the ground than" the front.

In practice' it is arranged, that the ploughs cut about half of the full Working depth in front, Whilst' on the return journey the second half is .cut. The ploughs are fitted with renewable shares and

mouldboards which can be altered in size according to the degree to which it is required to mix the topsoil and the subsoil. With the normal form of mouldboard, the top growth is effectively buried without bringing to any great extent the subsoil to the surface.

The ploughs are adjustable to work at depths from 12 ins. to 18 ins., and attachments are supplied so that the land can be left with a perfectly level surface, or ridging bodies fitted to make ridges 5 ft., 5 ft. 6 ins. or 6 ft:50centres at the same time.

The motor is of the "half-track type, being carried at the rear on twO'sets of rigid tracks, and at the front by a single central Steering vvheel. The main weight is suip,ported by the tracks through double, steel coil ,,springs mounted in the centre of each track sub-frame. .

Motive power is supplied by a sixc lindered petrol engine which de% lops 225 b.h.p. at 1,200 r.p.m. and provided with enclosed governor and separate throttle control

From the engine the drive is transmitted. through a.multiple dryPlate clutch toe the gearbox, a universal joint being fitted between the clutch and gearbox to take chassis stresses. :Four forward speeds are provided for the tracks (two slow speeds for ploughing and two 1aster speeds for travelling), two reverse speeds and two working speeds for the rotary ploughs.

The drive to the tracks is through separate multi Pie-disc clutches inside the gearbox, these being controlled from the driver's seat and

fitted with independent brakes workingon the outer drum of each clutch. By this means the drive to either track can be suspended and the track held stationary by the brake while the other track is driven round it for -quick :turning: From the clutches the drive is transmitted to the tracks on reither side by roller chains and spur gearing to the rear track wheels ,.mounted on: the main From the main gearbox" tbe drive is also .taken to the twin rings which carry the rotary ploughs, by double Coventry chain and bevel gearing, virliich is fully encased for protection from the dust and dirt of cultiva-1 tion. The framework carrying the rotary ploughs (and ridging bodies or grading blades when used) is hinged, on the same centre-line . as the. sprorts, of the driving chains, so that t e drive can be transmitted at any angle. The raising and lowering of tie framework is carried out through chains and segments from the lifting gear, which is driven from the cross-shaft at the front of the engine. When lowered into work, the weight of the framework is carried pa two adjustable tie-rods

which e fitted_ with heavy steel coil spruigs, which also regulate the depth of work.

The fr nt wheel is also steered by power rom the front cross-shaft, the whol forecarriage being rotated from th shaft by a rolleri chain, the mait frame being mounted on the fore ,arriage with a large ball bearing.

The driver's seat is arranged behind the gearbox in a position where he can best guide the implement and inspect the work done. All control levers are centralized at this point so that the driver can carry out all operations without leaving the footplate. When at work the implement is operated by one man. The fuel tank, at the front of the machine, carries sufficient supply for one full day's work.

A demonstration was recently • given with this machine in an arable field on the outskirts of Leeds before interested people, and its perform ance was highly praised. The first operation to be carried out was ordinary ploughing, grading blades being fitted at the sides and a harrow attached at the rear, The ploughs were set to work at a depth of 19 ins, and the soil was well churned and pulverized, leaving behind a level trail of evenly distributed tilth.

A. ridging implement was then attached, in place of the harrow and grader blades, and, in onekoperation, the ground was thoroughly ploughed and ridged.

The machine demonstrated was not designed for the conditions; of English agriculture, being tou.Iarge and weighing in working order about 20 tons. A smaller machine embodying the same principles could be satisfactorily adjusted to suit English conditions.