FUEL

Page 70

Page 71

If you've noticed an error in this article please click here to report it so we can fix it.

SAVER TYRES

The West German tyre giant is confident its E01 range really is different. Continental says the bette fuel consumption achievable makes tread li1 less important and regrooving unnecessary a best avoided

NOT ANOTHER NEW, I profile, low-rollingresistance truck tyre claim to better fuel consumption by x r cent? That will be the reaction among sceptical hauliers when thc hear that Continental has launchel its EOT (Energy Optimised Tyre range of 80 per cent aspect ratio tyres (those with a section height about 80 per cent of section widtl

Continental, the West German gro whose brands now also include Sem]: and Uniroyal, is prepared for that kit of response.

The scale of the fuel economy improvement it claims can be achievi simply by fitting a set of its new tyre place of any others currently in use least five per cent on average — indic just how confident the company is th this tyre's performance is significantb different from the rest.

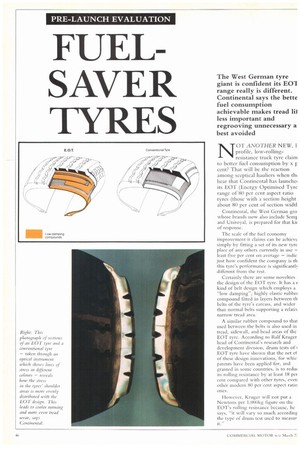

Certainly there are some novelties the design of the EOT tyre. It has a kind of belt design which employs a "low damping", highly elastic rubbei compound fitted in layers between th belts of the tyre's carcass, and wider than normal belts supporting a relatil narrow tread area.

A similar rubber compound to that used between the belts is also used in tread, sidewall, and bead areas of the EOT tyre, According to Ralf Kruger head of Continental's research and development division, drum tests of EOT tyre have shown that the net ef of these design innovations, for whic: patents have been applied for, and granted in sonic countries, is to redu( its rolling resistance by at least 18 pet cent compared with other tyres, even other modern 80 per cent aspect ratio ones.

However, Kruger will not put a Newtons per 1,000kg figure on the FOT's rolling resistance because, he says, 'it will vary so much according the type of drum test used to measur It." kNOTHER MAJOR advantage of the wide belt narrow tread area design, according to ager, is less defOrmation at speed in contact patch area and thus more n wear and extended tread life, titularly with the EOT steer-axle id pattern. The results of extensive road trials of EOT tyres by truck 1 bus manufacturers, notably MAN 1 Mercedes, are being used by ntinental to support its claims. k 10 per cent reduction in the total ling resistance of a truck or bus will Lilt in about a two per cent 3rovement in its fuel economy, that is ierally agreed. One of the reasons for increasing popularity of low-profile, per cent aspect ratio truck tyres at the

■ ense of tyres with deeper sidewalls, 11R 22.5s is their inherently lower ling resistance.

La factor of 1.0 is taken for the ling resistance of a laden 10.00 x 20 ss-ply tyre on smooth asphalt, an Z. 22.5's radial-ply tyre's rolling istance factor will be about 0.7 while 75/80 R 22.5 (the I IR 22.5's low&tie equivalent) will have a factor of nit 0.644. Continental's claims for its v tyre makes its rolling resistance or as low as 0.515.

/chicle manufacturers have taken a lot ire notice than operators of any tyre nufacturer's claim for lower rolling istance so far. An operator is more :ly to choose a low-profile tyre on grounds of lower chassis height, and ver kerb weight, while his primary Isideration in the choice of any tyre is -.1),r to he tread life.

ON'I'INENTAL is aiming to persuade operators that with the .........1amount of fuel cost saving that )ossible with its EOT tyres, tread life mid no longer be considered the most important criterion by which a tyre is judged. The company supports that contention like this: as a proportion of total operating cost, tyrc costs are small, from three to five per cent, and are tending to fall as tread life improves.

In contrast, fuel COSTS, which have been rising since the early Seventies and seem certain to continue to do so, now account t-or "up to 40 per cent of total operating costs."

Therefore, argues Continental, a fuel consumption saving of the order of five per cent has a much greater influence on total operating cost than considerably greater percentage increases, say as much as 30 per cent, in tyre life.

"Before EOT existed, the vehicle operator calculated die overall COST of tyres from the purchase price, mileage attained and the proceeds from the carcass. With EOT he will have to take fuel and tyre costs together," says Helmut Gieselmann, the group's Continental brand manager.

Evidently Continental recognises that at present British operators may be less willing to accept that argument than many of their counterparts in mainland Europe. EOT tyres will not become available here until early next year while their introduction to all other European markets is imminent.

They will carry a price premium over existing equivalent sized Continental tyres of between five and 15 per cent and will be available in five sizes, all but one nominally 80 per cent aspect although the precise ratio of section width to section height is not 80 in every case. The sizes are 275/80 R22.5, 295/80R 22.5, 315/80 R 22.5. 365/70 R 22.5 and 365/80 R 20.

Three tread patterns designated I1S80, HI382 and HS81 will be available, to suit respectively steered, drive and trailer axles.

The relatively low temperature at which the EOT tyre runs at high speed, 20 deg C less than a conventional tyre at 100km/h at full load, not only reduces the likelihood of casing failure in service, says Kruger, but makes the new tyre particlarly well suited to both hot and cold retreading processes. Furthermore, it is claimed that the tyre will not lose its low rolling resistance properties after retreading.

CONTINENTAL'S position on the subject of regrooving is likely to be a bone of contention with many British operators. The company says that generally it does not recommend regrooving. but particularly not on EOT tyres because the layer between the belt and tread rubber is not abrasion resistant, and so could easily be damaged following less than very careful regrooving.

Nevertheless, while arguing strongly that the economics of using EOT tyres makes regrooving unnecessary, Continental does not expressly forbid it.

It remains to be seen how many British operators will be persuaded to abandon traditional truck tyre costing methods, including regrooving, in favour 01 the latest in truck tyre technology.

Continental expects that in West Germany, its strongest market, about 10 per cent of its truck and bus tyres sold this year will be of the EOT type, and that proportion is expected to grow to 50 per cent within five years.

• by Tim Blakemore