VALUABLE ADVICE ON STEAM WAGONS.

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

Useful Tips from Our Driver and Mechanic Readers.

A USEFUL suggestion is embodied in letter from " G-.P.H.," of Deptford. He has evidently a fair amount of trailer work to do, and this frequently involves, as most steam-wagon drivers will readily confirm, some difficult manceuvres in order to persuade the trailer to go where its presence is required. This kind of -work often necessitates using the steam wagon as a pusher, propelling the trailer from the rear while the driver's mate guides it at the front by the aid of the towbar. Now the medium through which the push is transmitted from wagon to trailer is, most frequently, an old pole or batten.

This iS an extremely dangerous proceeding, as, if the pole slips, the result is likely to be serious injury to. or even the death of, the man holding it. A proper iron pushbar is easily and cheaply made, and ought, in the opinion of " G.P.H.," to be part of the regular equipment of every steamer and trailer.

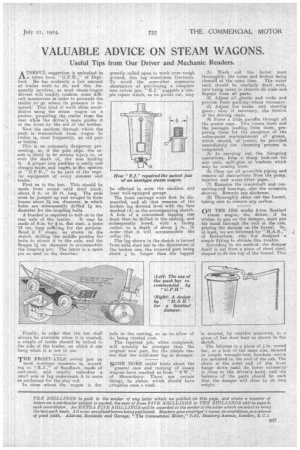

First as to the bar. This should be made from round mild steel stock, about 8 ft. or 10 ft. long. The ends must be jumped up and swaged to form bosses about 2i ins, diameter, in which holes are subsequently drilled 14 ins. dianieter for the coupling bolts,

A bracket is required to bolt on to the rear axle of the trailer, It may be made of 4-in. by 4-in, flat steel, a piece 14 ins, long sufficing for the purpose. Bend it U shape, as shown in the sketch, drilling the middle portion for bolts to attach it to the axle, and the flanges 1 ins, diameter to accommodate the coupling pin. The latter is a spare pin as used on the drawbar.

nuttily, in order that the bar shall always be available when it is wanted, a couple of hooks should be bolted to the side of the trailer, on which it can hang when it is not in use.

THE FRONT-AXLE swivel jaw on most overtype steamers is, according to "E.J., ' of Sandbach, made of cast-steel, and usually embodies a small arm or log underneath it to servo as anchorage for the stay rod. In cases where the wagon is

Ire

quently called upon to work over rough ground, this lug sometimes fractures. To avoid the somewhat expensive alternative of purchasing a complete new swivel jaw, "E.J." suggests a simple repair which, as he points out, may be effected in even the smallest and least well-equipped garage.

The front carriage must first be 'dismantled, and all that remains of the broken lug dressed level with the face marked (A) in the accompanying sketch. A hole of a convenient tapping size must then be drilled in the casting, and subsequently bored, with a facing cutter, to a depth of about 1„ in., in order that it will accommodate the collar (B).

The lug shown in the sketch is turned from mild steel bar to the dimensions of the broken one, the screwed part being about 4 in longer than the tapped

hole in the casting, so as to allow of its being riveted over.

The repaired job, when completed, will actually be stronger than the original new part, for the simple reason that the mild-steel lug is stronger.

SOl'ilE MORE useful hints about the general care and running of steam wagons have reached us from " S.W.," of Shrewsbury. There are certain things, he states, which should have attention once a week. (1) Wash out the boiler most thoroughly, the tubes and firebox being cleaned at the same time. The water tank should be similarly dealt with, care being taken to remove all scale and deposit from all parts. (2) Adjust all glands and cocks and provide fresh packing4where necessary. (3) Adjust. the brake and steering gears ; also, if necessary, the tension of the driving chain.

(4) Force a little paraffin through all the grease cups. This cleans them and the passages leading from them, preparing them for the reception of the subsequent replenishment of grease, which should, of -course; be provided immediately the cleansing process is completed.

(5) In carrying out the foregoing operations, keep a sharp look-out for any nuts, split-pins or washers which may be coming loose.

(6) Clear out all accessible piping and remove all obstructions from the pump, injector and water-lifter pipes.

(7) Examine the crankshaft and connecting-rod bearings, also the eccentric. sheaves. Remedy any slackness. (8) Thoroughly dean out the funnel, taking care to remove any carbon.

ON THE 1016 model 6-ton Sentinel steam wagon, the driver, if he wishes to put on the damper, must put his hand through the roof of the cab, placing the damper en the funnel. So, at least, we are informed by " H.A.B.," of Rotherham, who has designed a simple fitting to obviate this tronble. According to his method, the damper itself is cut from a piece of sheet steel, shaped to fit the top of the funnel. This is secured, by suitable setscrews, to a i piece of bar steel bent as shown n the sketch.

The fulcrum is a piece of Lin. round bar, or a bolt of the same size, secured in simpia wrought-iron brackets which are mounted on the roof of the cab. The chain at the outer end of the lever hangs down until its lower extremity is close to the driver's hand, and the balance of the parts should be such that the damper will close by its own weight.