R enault's fortunes have definitely taken a turn for the better

Page 29

Page 30

Page 31

Page 32

If you've noticed an error in this article please click here to report it so we can fix it.

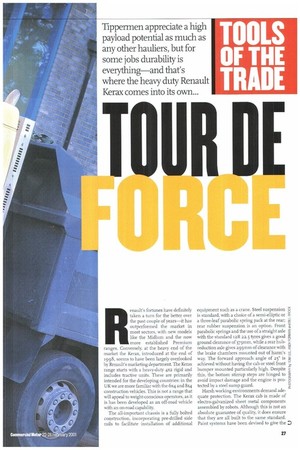

over the past couple of years—it has outperformed the market in most sectors, with new models like the Midlum and the now more established Premium ranges. Conversely, at the heavy end of the market the Kerax, introduced at the end of 1998, seems to have been largely overlooked by Renault's marketing department. The Kerax range starts with a heavy-duty 4x2 rigid and includes tractive units, These are primarily intended for the developing countries: in the UK we are more familiar with the 6x4 and 8x4 construction vehicles. This is not a range that will appeal to weight-conscious operators, as it is has been developed as an off-road vehicle with an on-road capability.

The all-important chassis is a fully bolted construction, incorporating pre-drilled side rails to facilitate installation of additional

equipment such as a crane. Steel suspension g is standard, with a choice of a semi-elliptic or SS a three-leaf parabolic spring pack at the rear; rear rubber suspension is an option. Front I parabolic springs and the use of a straight axle with the standard 12R 22.5 tyres gives a good ci ground clearance of 375mm, while a rear hubreduction axle gives 295mm of dearance with .? the brake chambers mounted out of harm's tr way. The forward approach angle of 25° is achieved without having the cab or steel front bumper mounted particularly high. Despite this, the bottom stirrup steps are hinged to avoid impact damage and the engine is prog

tected by a steel sump guard. 0_= Harsh working environments demand adequate protection. The Kerax cab is made of electro-galvanized sheet metal components assembled by robots. Although this is not an absolute guarantee of quality, it does ensure that they are all built to the same standard. Paint systems have been devised to give the

NI Building, civil engineering, plant hire and demolition contractor PJ Carey has been operating from its headquarters close to the twin towers of Wembley (yes, they're still there) for the past 30 years. Plant director Sean O'Donnell, has ro tippers in a 2o-strong fleet featuring Volvos, Ivecos and Scanias, and six of the multiwheelers are Kerax 8x4s.

"We ran Maxters for five years and part. exchanged them for the Kerax," he says. "It's company policy to buy all equipment outright. With Renault we have a buy-hack deal, so we know what the price will be in five years' time. They are 34ohp models with the nine-speed box.

We stipulate steel suspension—it gives better stability for off.

road work, and greater

axle articulation means better trac

tion than is possible with rubber suspension. We have never had a spring break. Ground clearance is good, with items like brake chambers mounted out of the way above the axles.

"The Keraxes are averaging 7.0mpg, which might not sound too good, but it's better than some of our earlier trucks. They average about 75,000km a year so we can expect to get five years out of them without any major component failures. Clutches last for two-and-a-half to three years. Running onto landfill sites we get through a lot of tyres, so we fit regrade Michelins.

"Rear drums and linings need replacing after 12 months. The fronts last a bit longer, but they should give a longer life overall. Discs might be a bit quicker and easier to service, but I don't think they would be suitable to work in the muck. A gearbox on one truck gave a bit of trouble; it turned out to be a faulty valve for the air-assisted gearshift. On another we damaged the third differential gear, arid we're still talldng about that. In general we like the price of the vehicle, and servicing and parts availability are good.

"Drivers always like more power, but here the power-to-weight ratio is adequate. Our first cabs are now three years old, and they're still looking OK. They're more comfortable than the Maxter, so the drivers like them. The Kerax stands up to the work pretty well."

structure effective protection, inside and out. The cab gets a uniform 20-micron layer of paint applied by electrolysis; it is then plunged into a cataphoretic bath which adds a further 35-micron undercoat, and finally receives a 45micron top coat.

The interior spec is of a high standard for a construction vehicle. Air conditioning is an option, and the ventilation system incorporates a fine filtration intake. The steering wheel is adjustable through a 30° arc, and the steering column moves up and down by 9omm. Fingertip control for the radio, a la Premium, is also standard. Electrically heated and adjusted mirrors are included on this year's models, but earlier examples are only heated. A single key operates the central locking, the immobiliser if fitted, and the ignition. We imagine there is little call for anything other than the Premium-style day cab for site work, but the Kerax can also be supplied with a sleeper cab, without a rear window but complete with full-width bunk, programmable heater, perimeter curtains and lateral exhaust. Headlamps are mounted in the front bumper. The lenses, with protective grilles, swing out as a unit to make bulb replacement easy.

There are two six-cylinder engines and four power options covering the six and eight. wheelers, but only three are available in the UK. The six-wheeler comes with the 9.8-litre unit rated at 298hp; and the 338hp version, generating i,18 ilbft of torque at 1,200rpm, is specified for the eight-wheeler alongside the ir.r-litre engine rated at 381hp, providing torque output Of 1,2 921bft (also at 1,20 orpm). The bigger engine can be specified with the Jacobs engine brake.

Now that ZF has taken over Renault's transmission production, the B9 and B 18 gearboxes are still available alongside ZF's own eight-speed 8S-151 and 168-151. These are compatible with the ZF Intarder transmission brake, but this is not included as an option on the spec sheet. Despite being the first manufacturer to offer disc brakes on a production vehicle, Renault is dragging its heels when it comes to the tipper chassis which is still fitted with drums all round. The system includes ABS as an option, but not traction control.

At the beginning of February this year a 400hp model joined the range, but the warning triangle, apparently surplus to requirements, has been deleted from the spec sheet. Eby Bill Brock