A Spark-ignited Heavy-oil Engine

Page 242

If you've noticed an error in this article please click here to report it so we can fix it.

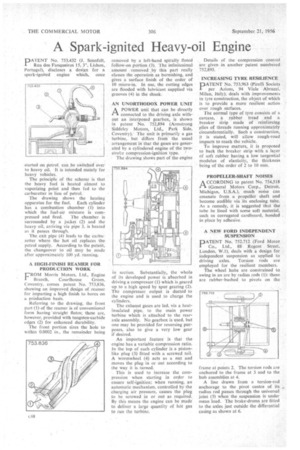

PATENT No. 753,432 Sennfelt, Rua dos Fanqueiros 15, 3°, Lisbon, Portugal), discloses a design for a spark-ignited engine which, once

started on petrol, can be switched over to heavy oil. It is intended mainly for heavy vehicles.

The principle of the scheme is that the heavy fuel is heated almost to vaporizing point and then fed to the carburetter in lieu of petrol.

The drawing shows the heating apparatus for the fuel. Each cylinder has a combustion chamber (1) into which the fuel-air mixture is corn pressed and fired. The chamber is surrounded by a jacket (2) and the heavy oil, arriving via pipe 3, is healed as it passes through.

The exit pipe (4) leads to the carburetter where the hot oil replaces the petrol supply. According to the patent, the changeover to oil may be made after approximately 100 yd. running.

A HIGH-FINISH REAMER FOR PRODUCTION WORK UROM Morris Motors, Ltd., Engine

13rarich, Courthouse Green, Coventry, comes patent No. 753,836, showing an improved design of reamer for imparting a high finish to bores on production basis.

Referring to the drawing, the front part (1) of the reamer is of conventional form having 'straight flutes; these are, however, provided with tungsten-carbide edges (2) for enhanced durability.

The front portion sizes the hole to within 0.0002 in., the remainder being

removed by a left-hand spirally fluted follow-on portion (3). The infinitesimal amount removed ,by this part really classes the operation as burnishing, and gives a surface finish of the order of 10 micro-in. In use, the cutting edges are flooded with lubricant supplied via grooves (4) in the shank.

AN UNORTHODOX POWER UNIT

AA POWER unit that can be directly connected to the driving axle without an interposed gearbox, is shown in patent No. 752,894 (Armstrong Siddeley Motors, Ltd., Park Side, Coventry); The unit is primarily a gas turbine, but differs from the usual arrangement in that the gases are generated by a cylinclered engine of the twostrae compression-ignition type.

The drawing 'shows part of the engine 'n seetion. Substantially, the whole of its developed power is absorbed in driving a compressor (1) which is geared up to a high speed by spur. gearing (2). The compressor output is ducted to the engine and is used to charge the cylinders.

The exhaust gases are led, via a heatinsulated pipe, to the main power turbine which is attached to the rearaxle assembly. No gearbox is used, but one may be provided for reversing purposes, also to give a very low gear if desired.

An important feature is that the engine has a variable compression ratio. In the top of each cylinder is a pistonlike plug (3) fitted with a screwed tail. A .wormwheel (4) acts as a nut and moves the plug in or out according to the way it is turned.

This is used to increase the compression when starting in order to ensure self-ignition; when running, an automatic mechanism, controlled by the charging air pressure, causes the plug to be screwed in or out as required. By this means the engine can be made to deliver a large quantity of hot gas to run the turbine. Details of the compression control are given in another patent numbered 752,895.

INCREASING TYRE RESILIENCE

PNo. 753,963 (Pirelli Societa per Azioni, 94 ViaIe Abruzzi, Milan, Italy), deals with improvements in tyre construction, the object of which is to provide a more resilient action over rough surfaces.

The normal type of tyre consists of a carcase, a rubber tread and a breaker strip made of reinforciog plies of threads running approximately circumferentially. Such a construction, it is stated, will allow rough-road impacts to reach the vehicle.

To improve matters, it is proposed to back the breaker strip with a layer of soft rubber having a low tangential modulus of elasticity, the thickness being of the order of 2 to 10 mm.

PROPELLER-SHAFT NOISES

A CCORDING to patent No. 754,518 1-1. (General Motors Corp., Detroit, Michigan, U.S.A.), much noise can emanate from a propeller shaft and become audible via its enclosing tube. As a remedy, it is suggested that the tube be lined with some soft material, such as corrugated cardboard, bonded in place by adhesive.

A NEW FORD INDEPENDENT SUSPENSION

PATENT No. 752,712 (Ford Motor Co., Ltd., 88 Regent Street, London, W.1), deals with a design for independent suspension as applied to driving axles. Torsion rods are employed for the resilient members.

The wheel hubs are constrained to swing in an arc by radius rods (I): these are rubber-bushed to pivots on the

frame at points 2. The torsion rods are anchored to the frame at 3 and to the hub assemblies at 4.

A line drawn from a torsion-rod anchorage to the pivot centre of its radius rod passes through the universal joint (5) when' the suspension is under mean load. The brake-drums are fitted to the axles just outside the differential casing as shown at 6.