For Drivers, Mechanics, and Foremen.

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

We revive this popular C.IVI:' feature -in connection with our "Keep Your Lorry Fit" Series, and offer a prize of ONE GUINEA for the best communication concerning any chassis to which reference has been made in that series.

Other letters on subjects of interest will be paid for on publication at the rate of One Penny a Line, and failing any award of the above prize, TEN SHILLINGS will be paid for the best letter published each week. .Mention your employer's name, in confidence, as evidence of good faith. Address 1)., M, and F., " The Commercial Motor," 7-15, Bosebery

Avenue, London, E.O. .

Lamps Alight.

On Saturday, 23rd September, light your lamps at 7.27 in London, 7.41 in Edinburgh, 7.34 in Newcastle, 7.40 in Liverpool, 7.35 in Birmingham, 7,37 in Bristol', and 7.58 in Dublin.

For Dublin the local mean time (one hour after sunset) is given; if Greenwich time is required, 23 minutes must be added.

Fibre for Fan Blades.

[1596] "J.0." (Deptford) writes :—" I notice on page 19 of your issue of 31st August last dealing with supplies for heavy-vehicle owners, a notice to the effect that Mr. J. Elgey, of Seaha.m Harbour, is able to supply fan blades of three-ply wood. I gather from this that a, little experience of my own in regard to this same matter may be of interest to those of your readers who have had trouble in connection with broken fan blades.

" On a 15-cwt. lorry which I have been driving since 1913, the fan is a four-blade one, and owing to a slight accident two of these blades broke, and a third one cracked. It was necessary for me to repair the fan and get it in working order as quickly as possible, as we had not time to send for a spare. I therefore removed the remaining and unbroken blade and used it for a template to make a new set. For materials I tried in succession sheet zinc, copper, and finally sheet fibre similar to the sample enclosed. The lastnamed proved most satisfactory and has been in continuous use since. Blades of this material are very easily made, and appear capable of standing any engine speed without being destroyed. Furthermore, if the fan should by chance, after adjustment, catch either of the water pipes, it does not necessarily break, but may bend a little.

"The fan fitted with these blades has now been running for 18 months and has given every satisfaction. In addition to the advantages above named, it possesses the feature of lightness. As regards cost, the materials for a new set of blades can be bought for about a'shilling."

Lubricating Wheel Bearings.

[The following article by 4 lady driver, haq been awarded the l'Os prize this week.]

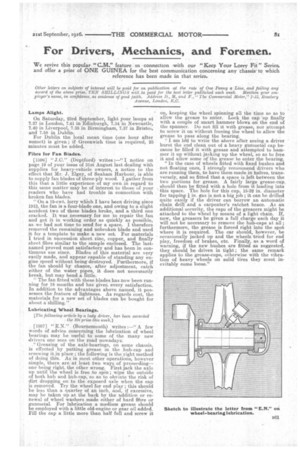

[1597] " E.N." (Bournemouth) writes :—" A few words of advice concerning the lubrication of wheel bearings may be useful to some of the many new drivers one sees on the road nowadays:

." Greasing of the axle-bearings, on some chassis, is effected by putting grease in the hub-cap and screwing it,in place.; the following is the right method of doing this. As in meet other operations, however simple,. there are at least two ways of proceeding— one being right, the other wrong. First jack the axle up until the wheel is free to spin; wipe the outside of both hub and hub-cap, so as to obviate the risk of dirt dropping on to the exposed axle when the cap is removed. Try the wheel for end play ; this should be less than a quarter of an inch, and, if excessive, may be taken up at the back by the addition or renewal of wheel washers made either of hard fibre or gunmetal. For lubrication a medium grease should be employed with a little old-engine or gear oil added. Fill the cap a little more than half full and screw it on, keeping the wheel spinning all the time so as to allow the grease to enter. Lock the cap up finally with a couple of smart hammer blows on the end of the spanner. Do not fill it with grease, nor attempt to screw it on without freeing the wheel to allow the grease to pass along the bearing. " I am ied to write the above after seeing a driver burst the end clean out of a heavy gunmetal cap because he filled it with grease and attempted to hammer it up without jacking up the wheel, so as to free it and allow some of the grease to enter the bearing. "In the case of wheels fitted with fixed bushes and not floating ones, I strongly recommend drivers who are running them, to have them made in halves, transversely, and so fitted that a space is left between the two portions for grease. A fairly large grease-cup should then be fitted with a hole from it leading into this space. The hole for this cup, 15-32 in. diameter for tapping I in. gas is not a big job ; it can be drilled quite easily if the driver can borrow an automatic chain drill and a carpenter's ratchet brace. As an additional security, the caps of the greasers might be attached to the wheel by means of a light chain. If, now, the greasers be given a full charge each day it will not be necessary to remove the hub-caps at all ; furthermore, the grease is forced right into the spot where it is required. The car should, however, be occasionally jacked up and the wheels tried for end play, freedom of brakes, etc. Finally, as a word of warning, if the new bushes are fitted as suggested, they should be driven in tight; the same remark applies to the grease-cups, otherwise with the vibration of heavy wheels on solid tires they must inevitably come loose."