B URTON'S first brewers were the monks of Burton Abbey, whose

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

example was soon followed by numerous innkeepers. In the early days of the industry, all beer produced in an establishment was drunk on the premises, but the suitability of Burton's natural resources for the production of fine ales soon became widely recognized, with the result that many breweries were bUilt in the town

For many years the bulk of the production was consumed within a small area and was distributed by horse-drawn vehicles. The expansion of the industry soon brought transport problems, however, for output began to' outstrip local consumption and brewers were obliged to look for markets farther afield. The Navigation Act opened up certain waterways, and during the last century the canal system was extensively used.

A n opportunity 10 r developing markets through

out the country was provided by the advent of• railway transport. Finally came the introduction of motor lorries, which opened up entirely new possibilities for brewery transport.

Britain's largest brewery concern is probably Ind, Coope and Allsopp, Ltd., which controls more than 3,000 licensed premises besides five breweries, nine bottling stores and 27 offices and stores, covering almost the whole of England and Wales. Each year this company • brews more than I m. barrels of beer. In round figures, this involves moving about 500,000 tons, including raw materials, finished products, barrels, bottles, cases and empties for return.

500,00 0 Tons a Ye ar for a Br ewer

"As the only brewery at Burton which transports beer throughout the country, both in bottle and in cask, its transport , system has been arranged to suit its special problems. The group's transport arrangements can conveniently be considered under the three headings of inwards transport, internal transport and distribution.

The term "inwards transport" covers the movement of raw

materials such as barley, sugar, hops, coal and other fuels, and returned empty containers. Much of this traffic is handled by rail, but since the establishment of the National Coal Board quite a large proportion of the coal is delivered to the brewery in the Board's own lorries.

One of the most vital considerations is to ensure a steady flow of returned empty casks, cases and bottles, which form the major portion of inwards traffic. Road transport has proved greatly superior to rail for the prompt return of empties.

The internal transport arrangements are based on a well-planned railway system, operated by the cornpany's own staff, which connects with all main departments, motive power being provided by steam a n d electric locomotives and tractors for shunting.

In considering the advantages of various methods of delivery, the transport manager is guided mainly by comparative costs and efficiency of service to the customer. Distribution points have been established throughout the country. Delivery to customers within a radius of about 40 miles from Burton is effected by the company's own fleet of lorries. Similarly, the company's Romford brewery operates within an 80-mile radius and supplies London, Oxford, Colchester, Stroud, Luton and Ipswich.

The minimum of part-loading is ensured by a system of area deliveries. Customers are advised of the delivery days allotted to their area, and co-operate closely when ordering to fall in with the proper day of delivery. Within limits, delivery by the company's own lorries has proved the most satisfactory arrangement, as it gives the transport manager full control of fleet operation so that a high degree of flexibility can be achieved, enabling a prompt and personal service to customers to be maintained.

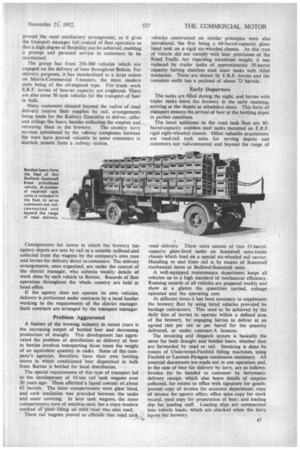

The group has from 250-300 vehicles which ,are engaged on the delivery of beer throughout Britain. For delivery purposes, it -has standardized to a large extent on Morris-Commercial 5-tonners, the most modern units being of the oil-engined type. For trunk work E.R.F. lorries of heavier capacity are employed. There are also some 50 tank vehicles for the transport of beer in bulk.

Many customers situated beyond the radius of road delivery receive their supplies by rail, arrangements being made for the Railway Executive to deliver, cellar and stillage the beers, besides collecting the empties and returning them to the brewery. The country lorry services introduced by the railway companies between the wars have proved valuable to some customers in districts remote from a railway station.

Consignments for towns in which the brewery has agency depots are sent by rail to a suitable railhead and collected from the wagons by the company's own men and lorries for delivery direct to customers. The delivery arrangements, once organized, are under the control of the district manager, who submits weekly details of work done by each vehicle to Burton. Records of fleet operation throughout the whole country are held at head office.

If the agency does not operate its own vehicles, delivery is performed under contracts by a local haulier working to the requirements of the district manager. Such contracts are arranged by the transport manager.

Problem Aggravated A feature of the brewing industry in recent years is the increasing output of bottled beer and decreasing production of draught. This development has aggravated the problem of distribution as delivery of beer in bottles involves transporting three times the weight of an equivalent quantity in casks. Some of the-company's agencies, therefore, have their own bottling stores in which conditioned beer dispatched in bulk from Burton is bottled for local distribution.

The special requirements of this type of transport led to the development of 10-ton rail tank wagons over 20 years ago. These afforded-'a liquid content of,about 65 barrels. The inner compartments were glass lined, and cork insulation was provided between the tanks and outer covering. In later tank wagons, the inner compartments. were of stainleSs steel, but a more modern method of glaxi-liding on Mad steel was also used. , These rail wagons proved so efficient that road tank,,

vehicles constructed on similar principles were also introduced, the first being a 60-barrel-capacity glasslined tank on a rigid six-wheeled chassis. As this type of vehicle did not comply with later provisions of the Road Traffic Act regarding maximum weight, it was replaced by trailer tanks of approximately 50-barrel capacity having stainless steel inner tanks with Alfol insulation. These are drawn by E.R.F. lorries and the complete outfit has a payload of about 72 barrels.

Early Departure The tanks are filled during the night, and lorries with trailer tanks leave the brewery in the early morning, arriving at the depots at scheduled times. This form of transport ensures the arrival of beer at the bottling depot in perfect condition.

The latest additions to the road tank fleet are 80barrel-capacity stainless steel tanks mounted on E.R.F. rigid eight-wheeled chassis. Other valuable acquisitions are road-rail tank units for serving depots and customers not rail-connected and beyond the range of road delivery. These units consist of two 35-barrelcapacity glass-lined tanks on Scarnmell semi-trailet chassis which load on a special six-wheeled rail carrier. Handling to and from rail is by means of Seammell mechanical horse or Bedford-Scammell units.

A well-equipped maintenance department keeps all vehicles up to a high standard of mechanical efficiency, Running records of all vehicles are prepared weekly and show at a glance the quantities carried, mileage operated and the operating cost.

At different times it has been necessary to supplement the brewery fleet by using hired vehicles provided by haulage contractors. This used to be achieved by the daily hire of lorries to operate within a defined area of the brewery, by engaging lorries to deliver at an agreed rate per ton or per barrel for the quantity delivered, or under contract-A licences.

The invoicing and dispatch system is basically the same for both draught and bottled beers, whether they are forwarded by road or rail. Invoicing is done by means of Underwood-Fanfold billing machines, using Fanfold or Lamson-Paragon continuous stationery. All essential documents are made out in one operation and, in the case of beer for delivery by lorry, are as follows: Invoice (to be handed to customer by lorryman); delivery receipt, which also bears details of empties ' collected, for return to office with signature for goods; journal copy of invoice for accounts department; copy of invoice for agency office; office sales copy for stock record, yard copy for preparation of beer; and loading slip for loading staff. Loading slips are summarized into vehicle loads, which are checked when the lorry leaves the' brewery.