MOVING A VILLA( MOTOR LORRY.

Page 16

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

THE GROWTH and development of the motor industry during the past decade are, even to . the placid mind, almost startling. Tasks deemed impossible of accomplishment a few years ago are now being successfully performed by motor lorry and trailer. Practically everything movable has been moved, and at frequent intervals we hear of some new triumph of motor engineering. The latest phase, of this development is the entire removal, from steeple to pump, of the village of Jennings, in the United States, to the town of Cadillac, 11 miles away.

Jennings, Michigan, was founded about a quarter of .a. century ago by the Mitchell Brothers Lumber Co. A saw-mill, chemical and flooring plant gave employment to approximately 500 men. Jennings was a " company town," and possessed churches, an " opera house," a; roller-skating rink, a community house, a band-stand, a jail, and other civic buildings, and a departmental store. Practically every able-bodied man in the village was employed in one of the three company mills. • .., When the village was founded, the unbroken hardwood forests surrounded the village for miles and miles in every direction. The company paid good wages, the needs of the inhabitants were simple, and life was ;nearly ideal. As the years rolled by; however, the standing timber around the village gradually disappeared before the axe and saw, and a few months ago, when the last of the big trees fell, it became only a Question' of time for the fires in the boilers to be drawn.

Various plans were considered for the preservation of the industrial life of the village, but all were discarded. The idea of moving the mills, the population, and the residences to Cadillac, 11 miles to the south-west, was then born, and the problem studied -from every angle. Many plans were Considered and rejected as impracticable before a:combination of motor harry and trailer was considered. Finally, Mr. W. A. Kysor' p fesident of the Acme Motor Truck Co., submitted a proposal, with the result that a gigantic trailer -was built. Some idea of the size of the trailer can be gathered froth the fact that it had to be built in the open.

The next thing to be considered was the road over which the 30 to 45-ton load would have to pass. Eight miles of the distance separating the two towns laid over a main highway, the rest of the way being over a fairly good dirt road. Considerable work had to be done over six miles of this stretch. The road bed had to be widened at a number of points, and in all cases of this kind heavy planks were laid to make a level roadway. Moreover, a river bridge had to be Widened and reinforced.

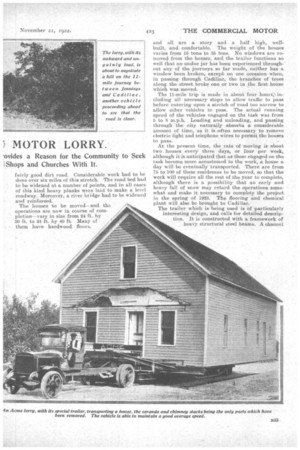

The houses to be moved—and the operations are now in course of completion—vary in size from 24 ft. by 30 ft. to 24 ft. by 40 ft. Many of them have hardwood floors. and all. are a story and a half high, wellbuilt, and comfortable. The weight of the houses varies from 15 tons to 35 tons. No windows are removed from the houses., and the trailer functions so well that no undue jar has been experienced throughout any. of the journeys so far made, neither has a window been brOken, excepb on one occasionwhen, in passing through Cadillac, the branches of trees along the street broke one or two in the first house which was moved.

The 11-mile trip is made in about four hours; including all necessary stops to allow traffic to pass before entering upon a stretch of road too narrow to allow other vehicles to pass. The actual running speed of the vehicles engaged on the task was from 5 to S m.p.h. Loading and unloading, and passing through the city naturally absorbs a considerable amount of time, as it is often necessary to removo electric light and telephone wires to permit the houses to pass. • At the present time, the rate of moving is about two. houses every three days, or four per week, although it is anticipated that as those engaged on the task become more accustomed to the work, a house a day will be eventually transported. There are from 75 to 100 of these residences to be moved, so that the work will require all the rest of the year to complete, although there is a possibility that an early and heavy fall of snow may retard the operations somewhat and make it necessary to complete the project in the spring of 1923. The flooring and chemical plant will also be brought to Cadillac.

The trailer which is being used is of particularly interesting design, and calls for detailed description. It is constructed with a framework of heavy structural steel beams. A channel and I-beam platform, raised 18 ins., above the trailer frame and rigidly connected to it, transfers the load at the forward end of the trailer to a rocking filth wheel mounted on the lorry. This ..construetion eliminates all twisting stresses from the trailer proper.

The trailer frame is supported at the rear luy four cast-stes1 lorry wheels disposed abreast and arranged in pairs. They are equipped with dual solid-rubber qres of 40-in. by 6-in. dimensions, and the wheels are placed under the. trailer in such a position that, approximately, 75 per cent. of the weight of the trailer and load is carriedon them, thus making it possible to carry a very heavy load on the trailer without overloading the lorry used for motive power. The trailer is designed safely to carry a maximum uniformly distributed load of 35 tons, and the complete unit weighs, approximately, 5 tons.

The trailer proper is 24 ft. wide by 42 ft, long. It consists of five longitudinal members of heavy sec

tion structural steel, securely held in place by two main and four supplementary transverse beams. Diagonal cross-braces are built into the frame to distribute the stresses. To give added rigidity and strength to the structure, the three centre longitudinal members are reinforced with large truss-rods securely anchored to the. member at each end and supporting the frame at equal intervals by cast-iron struts. The tension on these rods is equalized by a Series of turnbuckles, All frame connections, gussets, hraee.s, etc., are hot-riveted, and the whole makes an immensely powerful construction.

The platform at the forward end of the frame is so mounted that no distortion can be set up through any horizontal angularity between the tractor and the trailer. The connection between the platform and' the framework of the trailer is of ample strength, consisting of heavy gusset plates and channel beams. Experiment has shown that the disposition of the load—as to 25 per cent, upon the tractor a.nd 75 per cent, upon the trailer wheels—is reasonable and practical.

As we have already stated, the trailer wheels are arranged in pairs, each wheel running on tapered roller bearings carried on a tubular steel axle-shaft. The shafts of each pair of wheels are bolted together at the centre to a large steel casting which is supported by an extra-heavy wrought-iron pipe extending through it and at right angles to the shafts. Heavy steel pillow blocks at, each end of this pipe support the weight of the trailer and load, through coil springs which are attached to the trailer frame. This unique construction not only cushions the load, but Successfully provides for road inequalities. This is very essential when it is taken into consideration that the distance between the outside wheels is, approximately, 11 ft.

To relieve the springs from driving stresses, a radius rod, with flexible connections, is provided for both sets of wheels, the forward end of which is secured rigidly to the trailer frame and the rear end fastened to the end of the wrought-iron pipe through a swivelling connection. In order to maintain perfect alignment of all four wheels, the wrought-iron pipes supporting the axle-shaft§ are tied together by a system of flat bars secured to the trailer frame, and so arranged as to compensate for spring deflection.

Each house is raised to the trailer platform by a series of jacks located at each side. The two outside longitudinal members of the trailer, which are bolted on, ,are removed for this purpose, and the trailer is then backed under the building, and the house is lowered until it rests evenly on the trailer frame. The side-members are replaced if it is found necessary, and the unit is ready for its journey. ,

An Acme 125 chassis is used to draw this trailer. It is equipped with a Continental engine, developing 5.5 b.h.,p. This power, together with a gear reduction of, approximately, 7 to I. in first speed, delivers a tremendous torque. at the rear wheels, and :thus enables the lorry to negotiate a 6 per cent. gradient 600 ft. long, which is encountered over a gravel road, with a 35-ton load on the trailer.