For DRIVERS, MECHANICS & FOREMEN.

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

A PRIZE OF TEN SHILLINGS is awarded each week to the sender of the best letter which we publish on this page ; all others are paid for at the rate of a penny a line, with an allowance for photographs. All ?Wes are edited before being published. Mention your employer's name, in confidence, as evidence of good faith. Address, A, M. and F,, "The Commercial Motor," 7-15, Bosebery Avenue, London,. E.G. 1. , Lamps Alight—

Light your lamps at 6.45 in London, 7.31 in Edinburgh, 6.54 in Newcastle, 6.58 in Liverpool, 6.53 in Birmingham, 6.55 in-Bristol, and 7.39 in Dublin. The preceding times apply to Saturday, 23rd March. On Sunday, 24th March, when the clock is advanced one hour, the lighting-up times will be 62 mine, later.

An Unusual Cause of Loss of Power.

The sender of the following communication has been awarded the Ws. prize this week.

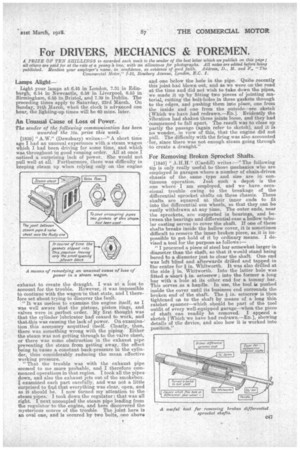

[1839] " A.W." (Dewsbury) writes:—" A short time ago I had an unusual experience with a steam wagon which I had been driving for some time, and which was, throughout in good running order. All at once I noticed a surprising lack of power. She would not pull well at all. Furthermore, there was difficulty in keeping steam up when relying only on the engine exhaust to create the draught. I was at a loss to account for the trouble. However, it was impossible to continue with the wagon.in that state, and I therefore set about trying to discover the fault. "It was useless to examine the engine itself, as I was well aware that the pistons, piston rings, and valves were in perfect order. My first thought was that the cylinder lubricator had ceased to work, and that:this was causing the lack of power. On examination this accessory acquitted itself. Clearly, then, there was something wrong with the piping. Either the steam was not getting through to the valve chest, or there was some obstruction in the exhaust pipe preventing the steam from getting away, the effect Toeing to cause a constant back-pressure in the cylinder, thus considerably reducing the mean effective working pressure.

"

"That the trouble was with the exhaust pipe seemed to me more probable, and I therefore commenced operation's in that region. I took all the pipes• down, and also the exhaust jets out of the smokebox. I examined each part carefully, and was not a little surprised to find that everything was clear, open, and as it should be. I now turned my attention to the steam pipes. I took down the regulator : that was all right. I next uncoupled the steam pipe leading from the regulator to the engine, and here discovered the mysterious source of the trouble The joint here is an oval one, and is secured by two bolts, one above and one below the hole in the pipe. Quite recently this joint had blown out, and as we were on the road at the time and did not wish to take down the pipes, we made it up by fitting two pieces of jointing material, cutting the bolt-holes in these gaskets through to the edges, and pushing them into place, one from the inside and one from the outside—see sketch [Which we have had redrawn.—En.]. Evidently the vibration had shaken these joints loose, and they had commenced to fall apart. The result was to close up partly the passage (again refer to sketch), and it is no wonder, in view of this, that the engine did not Pull. The difficulty with the firing was also accounted -for, since there was not enough steam going through to create a draught."

For Removing Broken Sprocket Shafts.

118401 " A.H.11." (Cardiff) writes :—" The following tip is unry really useful,to those mechanics who are employed in garages where a number of chain-driven chassis of the same type and size are in continuous operation. Just such a depot is the one where I am employed, and we have occasional trouble owing to the breakage of the differential sprocket shafts on these chassis. These shafts are squared at their inner ends to fit into the differential sun wheels, so that they can be easily withdrawn at any time. The outer ends, near the sprockets, are supported in bearings, and between the bearings and differential ease a hollow tubular casting serves to cover the Rhaft. If one of these shafts breaks inside the hollow cover,. it is sometimes difficult to remove the inner broken piece, as,it is impossible to get hold of it by ordinary means. I devised a. tool for the purpose as follows:— "I procured a piece of steel bar somewhat larger in diameter than the shaft, so that it would stand being bored to a diameter just to clear the shaft. One end was left blind and afterwards drilled and tapped in the centre for in. Whitworth. It was also drilled at the side in. Whitworth. Into the latter hole was fitted a rshQrt in. setscrew; into the former a. long bar with a hole at its other end for a tommy bar. This serves as a, handle. In use, the tool is pushed inside the cover until its business end surrounds the broken end of the shaft. The in, setscrew is then tightened on to the shaft by means of a long thin ratchet spanner—which should be part of the tool outfit of every well-equipped garage—when the piece of shaft can readily be removed. I append a sketch [Which we have had redrawn.—En.], showing details of the device, and also how it is worked into position."