Ford D300/Hands artic

Page 49

Page 50

Page 51

Page 52

If you've noticed an error in this article please click here to report it so we can fix it.

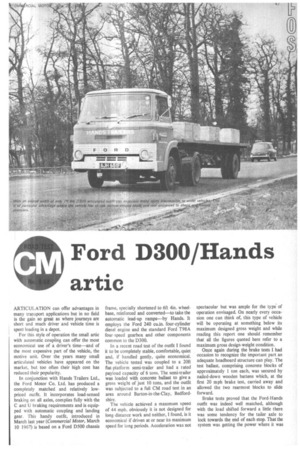

ARTICULATION can offer advantages in many transport applications but in no field is the gain so great as where journeys are short and much driver and vehicle time is spent loading in a depot For this style of operation the small artic with automatic coupling can offer the most economical use of a driver's time—and of the most expensive part of the vehicle, the motive unit. Over the years many small articulated vehicles have appeared on the market, but too often their high cost has reduced their popularity.

In conjunction with Hands Trailers Ltd., the Ford Motor Co. Ltd. has produced a completely matched and relatively lowpriced outfit. It incorporates load-sensed braking on all axles, complies fully with the C and U braking requirements and is equipped with automatic coupling and landing gear. This handy outfit, introduced in March last year (Commercial Motor, March 10 1967) is based on a Ford D500 chassis frame, specially shortened to 611 4in. wheelbase, reinforced and converted—to take the automatic lead-up ramps—by Hands. It employs the Ford 240 cu.in. four-cylinder diesel engine and the standard Ford T98A four-speed gearbox and other components common to the D300.

In a recent road test of the outfit I found it to be completely stable, comfortable, quiet and, if handled gently, quite economical. The vehicle tested was coupled to a 20ft flat-platform semi-trailer and had a rated payload capacity of 6 tons. The semi-trailer was loaded with concrete ballast to give a gross weight of just 10 tons, and the outfit was subjected to a full CM road test in an area around Barton-in-the-Clay, Bedfordshire.

The vehicle achieved a maximum speed of 44 mph, obviously it is not designed for long-distance work and neither, I found, is it economical if driven at or near its maximum speed for long periods. Acceleration was not

spectacular but was ample for the type. of operation envisaged. On nearly every occasion one can think of, this type of vehicle will be operating at something below its maximum designed gross weight and while reading this report one should remember that all the figures quoted here refer to a maximum gross design-weight condition.

Once again during the brake tests I had occasion to recognize the important part an adequate headboard structure can play. The test ballast, comprising concrete blocks of approximately 1 ton each, was secured by nailed-down wooden battens which, at the first 20 mph brake test, carried away and allowed the two rearmost blocks to slide forward.

Brake tests proved that the Ford-Hands outfit was indeed well matched, although with the load shifted forward a little there was some tendency for the taller axle to lock towards the end of each stop. That the system was getting the power where it was

needed in the shortest possible time cannot be doubted, for the average retardation from both 20 and 30 mph differed by only 0.2ft/s2. Actual stopping distances recorded ranged between 23 and 27.25ft from 20 mph and between 53.25 and 57ft from 30 mph. The best Tapley readings at the two speeds were (20 mph) 78 per cent and (30 mph) 75 per cent. A subsequent fade test showed a reduction of some 26 per cent over the best figure from 20 mph and although with such small wheel and drum equipment this must be expected, I must say that the fade effect lasted only for about two miles at 30 mph before the brakes recovered their

former high efficiency.

During the fuel consumption tests I found the rather considerable gap in the ratios between third and fourth gears to be detrimental to the good progress of the outfit. It could not be driven sensibly at comfortable speeds because the maximum rpm gave only 23 mph in third gear, and personally I found this speed too low for comfortable progess in top gear. While the vehicle took only 22.0sec to accelerate from 10 to 20 mph, in top gear—a figure to be expected—it took a further 19.8sec to reach 30 mph from 20. mph. Fuel consumption proved to be good, a figure of 15.0 mpg being recorded on the 30 mph fully laden run. Pushing the speed up to 40 mph raised the average journey speed by only 4.5 mph while at the same time pulling the consumption result down to 12.65 mpg. The average speed recorded on this run was close to the highest the machine could achieve and consequently I did not carry out a motorway test.

Handling throughout the test was excellent. Steering and the controls generally could not be faulted. Ile brakes in particular had a nice sensitive feel, allowing the driver to apply just the amount of retardation he needs without having to pay overmuch attention to what he is doing in order to prevent a snatch. Handling impressions are no doubt enhanced by the low noise level, a fact that gives an added sense of smooth and easy progress.

Manoeuvrability of this baby artic is excellent. The tractive unit had a turning circle of only 28.25ft while with the trailer used on the test the whole outfit could be swung round within a circle measuring only 37ft wall to wall. I found the vehicle very easy to handle in close quarters, although the nearside mirror would have been more useful had it been of the convex pattern. Gear ratios in first and reverse gears are just right for creeping in and out of restricted gateways and the like; they, and the excellent tractability of the engine at tick-over speeds, protect the clutch from unnecessary slipping and riding.

Hill-climbing performance was certain, if not spectacular. Although the machine took 5min 27.4sec to surmount Bison Hill, I got the distinct impression that the I in 6.5 gradient was by no means the steepest it would climb. Easy restarts were made in first and reverse gears, neither requiring an excessive punishment to the clutch. This latter component is quite distinctly sweet in operation; a driver would need to be hamfisted indeed to hand out transmission punishment even under the most adverse conditions. The parking brake, operated mechanically through a multi-pull ratchet, was able to stop the vehicle while on the roll both backwards and forwards on the I in 6.5 gradient but on the test vehicle the nearside driving wheel locked when checking the efficiency of this brake. • Too much has been written about the Ford D range cab to justify my going into detail here. It is enough to say that it seems to me to be all that a driver's cab should be, even in the standard form used on the test vehicle. From the engineer's point of view it is a tilt cab that really tilts sufficiently to allow access to almost any engine job. The tilting method is quick and simple and the fastenings are simple, but at the same time safe, and this I appreciate greatly.

The braking system employs air hydraulic r on the tractive unit, while the trailer brakes are operated by single-diaphragm air chambers, relay levers and links to wedgeoperated wheel units. The secondary system is achieved by having split air and hydraulic circuits on the tractive unit, while the trailer brakes are operated through the coupling dolly by a single air chamber and then by mechanical linkage to the trailer axle. The outfit has a third quite efficient brake in the tractive unit handbrake. Figures obtained with the secondary system and handbrake can be seen in the performance panel.

Construction or the semi-trailer is quite simple. Two rolled-steel side-members form the main frames, these being tied together by four cross-members formed from rolled-steel channel and by the forecarriage mounting plate. Pressed steel outriggers set at suitable intervals are, like the rest of the frame, electrically welded into position. The test trailer was 2Oft long by 7ft wide, the angle-iron rave-rails giving almost full-width floorspace. No headboard was fitted but this is an optional extra.

One of the hazards of automatic coupling operation in the past has been the risk of the driver pulling the wrong lever and causing the trailer to be dropped unwittingly. Hands have designed a special release-lever assembly which incorporates a safety lock making this mistake virtually impossible. Not only is the handle of the assembly made in such a way that it is removable, but there is also a double-baulking gate through which the lever must be moved to free the locking mechanism. I cannot imagine any condition where this control could be operated accidently. Picking up and dropping the trailer is simplicity itself, taking only a few seconds. The non-collapsible landing gear does not permit the ramp rollers to fall to a point lower than the lowest extremity of the lead-up ramps, so even in the event of partial collapse it is possible for the tractive unit to pick up the trailer again without difficulty.

Quite rightly in my opinion, the makers have made no attempt to facilitate automatic connection of lighting and braking units. The manual coupling of these systems can be carried out so quickly that to automate would give little operational advantage, whereas the shortcomings that can go hand in hand with automatic connections can be both dangerous and time consuming. However, in order that the tractive unit can be used with existing trailers with automatic couplings, two rubbing-contact pads to feed the earth-return lighting system are also provided.

When used with semi-trailers equipped only with the mechanical braking system common to the automatic coupling, the trailer brake service coupling on the tractive Unit is plugged into a slave air chamber which powers the brake operating spade in the coupling gear.

The tractive unit portion of the coupling is a new version of the Hands 3/5-ton automatic gear which was specially developed for the D300 unit. It secures the ramp rollers and is positively locked in the coupled position by an over-centre pawl mechanism. The trailer portion of the coupling incorporates a 15in.-diameter turntable. This large turntable area gives the vehicle more stability than is usual with automatic gear. All in all, coupled to the appropriate semi-trailer for the job in hand, the D300 ardc provides a most useful vehicle for local delivery or urban distribution work. Its manoeuvring qualities and deck height of only 36.5in. laden, at the rear axle, together with the undoubted flexibility and turn-round speed of the auto-coupled outfit give—for a list price of £1,903 as tested—a versatile and economically priced maid of all work.