Public Cleansing by Private Enterprise

Page 54

Page 55

Page 56

If you've noticed an error in this article please click here to report it so we can fix it.

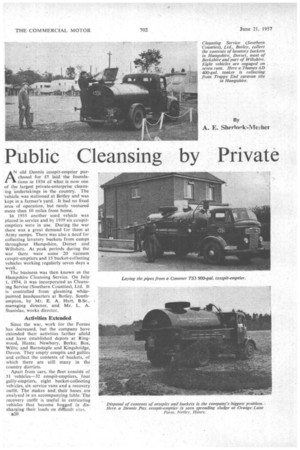

By A. E. Sherloek-Me 4ier AN old Dennis cesspit-emptier purchased for E5 laid the foundations in 1934 of what is now one of the largest private-enterprise cleansing 'Undertakings in the country. The vehicle was stationed at Botley and was kept in a farmer's yard. It had no fixed area of operation, but rarely ventured more than 10 miles from home.

In 1935 another used vehicle was placed in service and by 1939 six cesspitemptiers were in use. During the war there was a great demand for them at Army camps. There was also a need for collecting lavatory buckets from camps throughout Hampshire, Dorset and Wiltshire. At peak periods during the war • there were some 20 vacuum cesspit-emptiers and 15 bucket-collecting vehicles working regularly seven days a week.

The business was then known as the Hampshire Cleansing Service. On July 1, 1954, it was incorporated as Cleansing Service (Southern Counties), Ltd. It is ' controlled from gleaming whitepainted headquarters at Botley, Southampton, by Mr. E. A. Hart, B.Sc., managing director, and Mr. L. A. Stanislas, works director.

Activities Extended

Since the war, work for the Forces has decreased, but the company have extended their activities farther afield and have established depots at Ringwood, Hants; Newbury, Berks; Box, Wilts; and Barnstaple and Kingsbridge, Devon. They empty cesspits and gullies and collect the contents of buckets, of which there are still many in the country districts.

Apart from cars, the fleet consists of 51 vehicles-32 cesspit-emptiers, four gully-emptiers, eight bucket-collecting vehicles, six service vans and a recovery outfit. The makes and, their bases are analysed in an accompanying table. The recovery outfit is useful in extricating vehicles that become bogged in discharging their loads on difficult sites.

B20 The company buy 'chassis and cabs from local agents and themselves mount the tanks and equipment. The exhauster is driven by a single-cylindered oil engine mounted on a sub-frame behind the cab.

This is found to be a better arrangement than the usual method of running the exhauster off the power take-off, because the auxiliary engine can be governed to the correct speed of the exhauster and does not depend on the driver's judgment.

Bucket-collecting vehicles have elliptical tank bodies with a loading aperture on the top at the rear, which is reached by a full-width step between the chassis frame members.

, Operations are under B licences, permitting a radius of 100 miles from Botley and taking in Devon and Cornwall, and 70 miles from Box. The eastern boundary of the operational area is Petworth, Sussex. The boundary runs up through Henley, Oxon; Wantage, Berks; and Cirencester anti Stroud, Glos., and then down to Somerset, Devon and Cornwall.

Of the 35 vehicles based at Botley, one cesspit-emptier is garaged at Mid, burst, another at Petworth, two at Basingstoke and one at Salisbury. Service vans are used by the crews in travelling to and from their operating areas.

Drivers are extremely important to the organization, for they carry a great deal of responsibility for planning their work and as the company's ambassadors in a task requiring tact. Many of them have had long service.

All drivers receive I Is. a week more than the figure specified in the current Road Haulage Wages Order. In addition, drivers of bucketcollecting vehiclesare paid a 'bonus on their monthly takings and the drivers of gully-emptiers earn a bonus for emptying more than 550 gullies a week. Gully-emptying involves much lodging away from home, and the work has to be made attractive.

It has not been found practicable to devise a bonus system for the drivers of cesspitemptiers.

Cesspit emptying reaches a peak of activity in the spring, presumably, because the sub-soil water-level is higher than normal and the contents do not soak out of the pits so readily. There is also a high level of demand during the holiday season at seaside resorts, caravan camps and so on.

Bucket emptying maintains a steady level of activity throughout the year, although there is additional work at the Army summer camps. Gully emptying, too, is fairly regular, although once the leaves have fallen and again after severe frost or snow, if any quantity of grit has to be spread on the roads, there is a keen demand by councils for service.

Topographical conditions in the company's large area of operations are varied. Narrow roads and gateways abound and short-wheelbase vehicles with good steering locks arc necessary.

Mr. Hart told me that the biggest problem was to find disposal sites. Few councils allow the contents of cesspits to be discharged into their sewage systems and in most cases Cleansing Service (Southern Counties), Ltd., have to make their own arrangements for disposal with local farmers.

Cesspit sludge has a certain manurial value and at some seasons farmers are glad to have it spread on their ground, but at other times disposal presents difficulties. Sometimes the company are compelled to buy tons of baled straw to make bays in which to discharge their, loads.

In the case of gully emptying the council concerned are responsible for finding a disposal site, which is usually their house-refuse tip. The heavy sludge from buckets can never be discharged into sewers and arrangements have to be made with farmers, as in the case of the contents of cesspits.

In cesspit emptying the distance from the beat to the disposal point may be anything from a few yards to 10 miles. In gully emptying it is usually two or three miles. On bucket work the driver arranges his round so that he has approximately a full load by the time he reaches the disposal site.

Cesspits are emptied in 20 areas, each covering between 100 and 200 square miles. In each area an average of about 50 pits a week is cleared. A driver remains in his particular area so that

he gets to know it well and can plan his programme to reduce empty running as far as possible.

Frequency of cleansing depends on the efficiency of the overflow and the ability of the surrounding ground to absorb it. If situated in good drainage sub-soil, a cesspit might have to be emptied not more than once in 20 years, but new pits have to be completely watertight and may have to be cleared monthly.

The 32 cesspit-emptiers average 25,000 miles a year each. The Dennis and Dodge vehicles with Perkins P6 engines yield 15-16 m.p.g., the nine Commer TS3 models, 17-19 m.p.g., and the Dennis petrol-engined cesspitemptiers, 8-10 m.p.g.

Three gully-emptiers are regularly at. work and a fourth stands by to relieve at the various depots. An effort is made to keep each driver to the same jobs.

Each depot deals as far as possible with the gullies in its own area to avoid the difficulties of drivers having to lodge away from home for long periods. For work within 20-30 miles of Botley a van is usually provided for the workers. It is often possible to arrange for gullies at adjacent towns to be cleared at the same time. so that the 13.22 service van can transport two crews. Where temporary lodging away is necessary, it is shared equally between the drivers.

Each machine clears between 500 a,pd 1,000 gullies a week. Some gullies have to be cleared every three months, whereas others require service not more than once every six months.

Each gully-emptier averages 18,000 to 20,000 miles a year, the Cornrner TS3 giving 14 m.p.g., and the Karrier CK.3 and Dennis machines, 6-8 m.p.g.

Eight bucket-collecting vehicles are engaged on seven rounds covering Hampshire. Dorset, most of Berkshire and part of Wiltshire. They collect From country schools, Army camps, R.A.F. stations, private houses, small Factories, caravan sites and holiday camps. On an average, each vehicle, with driver and mate, clears about 200buckets a day and covers 600 miles a week.

Each driver has his fixed round for the day and is responsible for collecting cash, either on each visit or monthly, from householders. A charge of Is. per clearance is made to householders, who are served once a week.

Collections are usually made twice a week from schools and daily or three times a week from military camps. During the day a vehicle averages two loads, totalling about 4 tons.

On this work the annual vehicle mileage is 30,000 at a fuel-consumption rate of 25-26 m.p.g. for the Thames 4D 3-tonners and 14-15 m.p.g. for the Austin petrol-engined 2-ton tiers.

Service vans average 18,000 miles a year, the Austin A40 and Thames I0-cwt. models giving 30 m.p.g., and the Austin A35, 45 m.p.g.

A weekly profit-and-loss statement is prepared for each vehicle on a doublesided loose leaf on which two months' figures can be recorded. Daily mileage, fuel issued, miles per gallon and cost of fuel are itemized daily and wages and overheads weekly,Overheads comprise all charges other than for fuel and wages and are recorded as a lump sum, which is calculated in advance for each type of vehicle.

The sheet also shows total earnings, work done, profit or loss, and the description and cost of repairs. The balance for the bucket vehicles is extracted monthly.

All vehicles operating from Botley are serviced at the works every fortnight. Those at Ringwood are brought into headquarters in turn for service. Vehicles at other depots undergo maintenance every fortnight by a local garage.

In the event of difficulty, a driver at an outlying depot reports by telephone to the chief fitter and it is then decided whether the local garage can rectify the trouble or whether a fitter should be sent out from Botley. The latter course usually has to be taken if trouble occurs with an exhauster.

Fully Equipped

[he Botley works is equipped to undertake every mechanical job other than crankshaft grinding. Seven fitters work under the chief fitter and a yard man is responsible for issuing fuel, mending suction pipes and so on. Every cesspit-emptier carries 200 ft. of hose.

Equipment in the workshops, which are heated by waste-oil burners, includes an Ingersoll Rand compressor, a 5-ton hydraulic lift, a Uni-gun pressure-lubrication system, a 60-ton hydraulic press, a Van Norman boring bar, a Van Norman valve refacer, electric and acetylene welding plant, a 4-in. lathe, a Wickham crane, and Power hack saw, grinding and buffing machines, and drill.

Apart from minor items, such as nuts and bolts, all parts supplied to.a vehicle are noted, with the date of fitting. No attempt is made to cost individually each part fitted, as a summary of a spA'res supplied to any vehicle is found to give a sufficiently comprehensive picture.

A pahicularly closewatch is kept upon exhausters, which are costly, so that a vehicle can be withdrawn and new blades fitted before wear becomes serious.

Tyre Experience

Mainly Michelin Iv! tyres are used and the average life of a cover—regarding retreads as new tyres—is 25,000 miles. The Michelin M gives sufficient traction off the road, but still affords a fair total mileage.

A cross-country tread must be fitted because vehicles have to take their loads across fields for disposal. This is. howiver, only a small part of their work and on normal road operation cross-country treads wear more rapidly than a standard design.

The immediate impression of hygiene and efficiency given by the outward and inward appearance of the head office is sustained by the vehicles themselves, the chocolate and gold livery of which is repainted every two years.