WAYS AND MEANS.

Page 73

If you've noticed an error in this article please click here to report it so we can fix it.

Useful Contributions From Our Driver and Mechanic Readers.

A Useful Addition to a Garage Lathe.

MHE garage lathe is often called upon to do jobs that do not occur in general engineering shops, where many lathes of different kinds are employed; so this tool has to be a kind of jack of all trades. A correspondent, " of King's Cross, sends us a very practical suggestion for a simple addition to a lathe that will enable many jobs to be done with ease, and in less time than without it.

Supposing the lathe to be of the hollow-mandrel type, he fits a plug into the conical hole made for the centre and screws into the rear of this a long stem with a nut at the end, as shown. This bolds the plug firmly and truly in the mandrel. He then bores and cuts a thread in the front of the plug, so that it will take any kind of fitting, such as a stud for holding anything to the faceplate or driving plate.

Such articles as wheels that have to be re-bored can be held by a stud, nut and washer, whilst the outer part is set perfectly true; plates and bolts can be used to hold the wheel to the faceplate, and the stud removed so that the hole can be rebored.

' A shallow depression can be bored in the faceplate so as to form a register for anything for which it may be required, such as a true plug to centre some article while it is being turned on the outside. Bushes that have been held in the universal chuck and bored and faced at both ends can be held on a short register by means of a nut, washer and stud, while the outer surface is being turned.

Should the lathe be one of the older Makes, in which the mandrels are often solid, a hole can be bored at the end of the conical hole into which the centre fits and tapped to receive the stud.

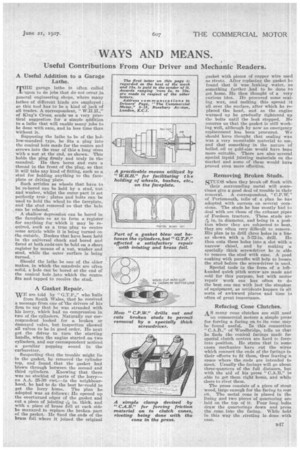

A Gasket Repair.

wE are told by " G.T.P.," who hails

from South Wales, that he received a message from one of 'the drivers of his firm to say that he was stranded with his lorry, which had no compression in two of the cylinders. Naturally our correspoit dent looked for a broken or damaged valve, but inspection showed all valves to be in good order. He next got the driver to turn the starting handle, when the engine started on two cylinders, and our correspondent noticed a peculiar popping sound in the carburetter.

Suspecting that the trouble might lie in the gasket, he removed the cylinder top, and found that the gasket had blown through between the second and third cylinders. Knowing that there was no stockist of parts of the lorry— an A.A. 25-30 cwt.--in the neighbourhood, he had to do the best he•could to get the lorry home. The plan he adopted was as follows: He opened up the overturned edges of the gasket and cut a piece of jointing ye in. thick, and with a piece of brass foil at each side he managed to replace the broken part of the gasket. He fixed the ends of the brass foil where it joined the original

gasket with pieces of copper wire used as rivets. After replacing the gasket he found that it was leaking water, $o something further had to be done to get home. He then thought of a very curious idea. He procured some sealing wax, and melting this spread it all over the outface, after which he replaced the head, and as the engine warmed up he gradually tightened up the bolts until the leak stopped. He assures us that the gasket is still working well, although by now an emergency replacement has been procured. We should have thought that sealing wax was. a very unsuitable material to use, and that something in the nature Of boiled, oil or gold-size would have been more suitable. There are also several special liquid jointing materials on the market and some of these would liars Proved even more effective.

Removing Broken Studs.

STUDS when they break off flush with

their surrounding metal will sometimes give a good deal of trouble in their removal. A correspondent, " C.P.W." of Portsmouth, tells of a plan he has adopted with success on several occasions. The studs he has mostly hail to deal with are those of the exhaust pipes of Fordson tractors. These studs are 19-6 in. in diameter, and being in a position where they are subjected to heat, they are often very difficult to remove. His plan is to drill three holes in a line

as shown with a 5-32-in. drill. He then cuts these holes into a 'slot with a narrow chisel, and by making a. specially thick screwdriver he is able to remove the stud with ease. A good soaking with paraffin will help to loosen the stud before the screwdriver is used.

Special tools in the form of a lefthanded quick pitch screw are made and sold for this purpose, but with motor repair work one has often to do the best one can with just the simplest of equipment, as accidents happen in all sorts of awkward places and time is often of great importance.

Refacing Cone Clutches.

AS many cone clutches are still used on commercial motors a simple press for forcing a facing on to its cone may be found useful. In this eonnectiop

of Woodbridge, tells us that he finds the conical facings made for special clutch centres are lard te force into position. He states that in sortie cases mechanics have cut the wires which connect the ends of the facings in their efforts to fit them, thug leaving 'a space where the ends are intended to meet. Usually the facings will go about three-quarters of the full distance, but with the aid of his press " C.A.B." is .able to get them right home, and while there to rivet them.

The press consists rtf a piece of stout wood, large enough for the facing to rest on. The metal cone is placed in the lining and two pieces of quartering are laid OD the top of it. Four long bolts draw the quarterings down and press the cone into the facing. While held in this way the riveting is. done with

ease. .