A BERLIN BUS WITH FRONT-WHEEL DRIVE.

Page 12

Page 13

Page 14

If you've noticed an error in this article please click here to report it so we can fix it.

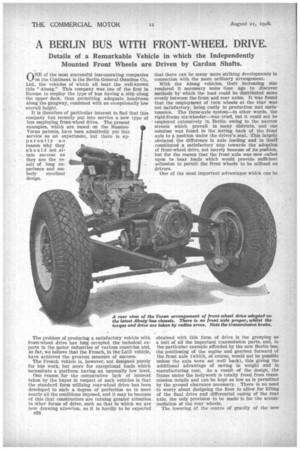

Details of a Remarkable Vehicle in which the Independently Mounted Front Wheels are Driven by Cardan Shafts.

ONE of the most successful bus-operating companies on the Continent is the Berlin General Omnibus Co., Ltd., the vehicles of which all bear the well-known title " Aboag." This company was one of the first in Europe to employ the type of bus having a step along the upper deck, thus permitting adequate headroom along the gangway, combined with an exceptionally low overall height.

It is therefore of particular interest to find that this company has recently put into service a new type of bus employing front-wheel drive. The present examples, which are based on the Bussien Voran patents, have been admittedly put into service as an experiment, but there is appar ent 1 y no reason why they should not attain success as they are the result of long experience and embody excellent design.

The problem of producing a satisfactory vehicle with front-wheel drive has long occupied the technical experts in the motor industries of various countries and, so far, we believe that the French, in the Lath l vehicle, have achieved the greatest measure of success.

The French vehicle is, however, not designed purely for bus work, but more for exceptional loads which necessitate a platform having an unusually low level.

One reason for the comparative lack of interest taken by the buyer in respect of such vehicles is that the standard form utilizing rear-wheel drive has been developed to such a degree of perfection as to meet nearly all the conditions imposed, and it may be because of this that constructors are turning greater attention to other forms of drive, such as that to which we are now drawing attention, as it is hardly to be expected c28 that there can be many more striking developments in connection with the more ordinary arrangement.

With the Aboag vehicles, their increasing size rendered it necessary some time ago to discover methods by which the load could be distributed more evenly between the front and rear axles. It was found that the employment of twin wheels at the rear was not satisfactory, being costly in production and maintenance. The three-axle system—in other words, the rigid-frame six-wheeler—was tried, but it could not be employed extensively in Berlin owing to the narrow streets which prevail in many districts, and one solution was found in the setting back of the front axle to a position under the driver's seat. This largely obviated the difference in axle loading and in itself constituted a satisfactory step towards the adoption of front-wheel drive, not merely because of its position, but for the reason that the front axle was now called upon to bear loads which would provide sufficient adhesion to permit the front wheels to be utilized as drivers.

One of the most Important advantages which can be obtained with this form of drive is the grouping asi a unit of all the important transmission parts, and, in the particular example afforded by the new Berlin bus, the positioning of the engine and gearbox forward of the front axle (which, of course, would not be possible unless the axle were set well back), this giving the additional advantage of saving in weight and in manufacturing cost. As a result of the design, the frame under the bodywork is totally freed from transmission details and can be kept as low as is permitted by the ground clearance necessary. There is no need -to worry about designing the floor to allow for lifting of the final drive and differential casing of the rear axle, the only provision to be made is for the accommodation of the rear wheels.

The lowering of the centre of gravity of the new bus renders the vehicle particularly safe, and its qualifications in this direction have shown themselves, especially while accelerating or braking. The side pressure when rounding curves at a good speed is considerably lessened, likewise the danger of overturning. It has also been found that the elimination of intermediate bearings for the extended propeller shafts which are necessary in the case of long. wheelbase vehicles having rear drive, and the con centration of the drive at the forward end appreciably reduce noise, and here, again, further comfort for the passengers is secured.

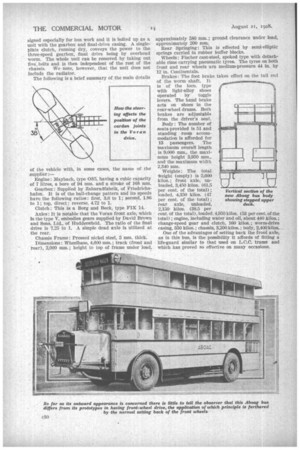

The new buses are of the enclosed-upper-deck pattern and they do not depart materially in external appearance from the latest models embodying rear-wheel drive. '

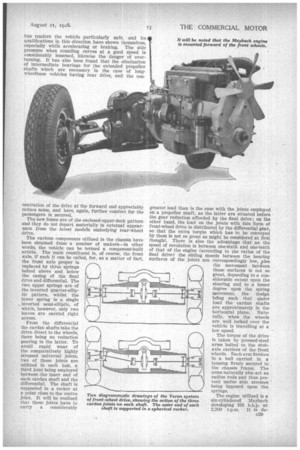

From the differential the cardan shafts take the drive direct to the wheels, there being no reduction gearing in the latter. To avoid rapid wear of the comparatively highly stressed universal joints, two of these joints are utilized in each hub, a third joint being employed between .the inner end of each cardan shaft and the differential. The shaft is supported in a rocker at a point close to the centre joint. It will be realized that these joints have to carry a considerably

greater load than is the case with the joints employed on a propeller shaft, as the latter are situated before the gear reduction afforded by the final drive; on the other hand, the load on the joints with this form of front-wheel drive is distributed by the differential gear, so that the extra torque which has to be conveyed by them is not so great as might be considered at first thought. There is also the advantage that as the speed of revolution is between one-sixth and one-tenth of that of the engine (according to the ratios of the final drive) the sliding speeds between the bearing surfaces of the joints are correspondingly low, iilso the movement between these surfaces is not so great, depending to a considerable extent upon the steering and to a lesser degree upon the spring movement, the design Wing such that under load the cardan shafts are approximately in the horizontal plane. Naturally,• when the wheels are well locked over the vehicle is travelling at a low speed.

The torque of the drive is taken by -pressed-steel arms bolted to the stubaxle carriers of the front wheels. Each arm fmishes In a ball carried in a housing firmly secured to the chassis frame. The arms naturally also act as radius rods and thus prevent undue side stresses being imposed upon the springs.

The engine utilized is a six-cylindered Maybach developing 105 b.h.p. at

2,200 r.p.m. It is de signed especially for bus work and it is bolted up as a unit with the gearbox and final-drive casing. A singleplate dutch, running dry, conveys the power to the three-speed gearbox, final drive being by overhead worm. The whole unit can be removed by taking out five' bolts and is then independent of the rest of the chassis. We note, however, that the unit does not include the radiator.

The following is a brief summary of the main details of the vehicle with, in some cases, the name of the supplier :— Engine: Maybach, type 035, having a cubic capacity of 7 litres, a bore of 94 min. and a stroke of 368 mm.

Gearbox : Supplied by Zahnradfabrik, of Friedrichshafen. It is of the ball-change pattern and its speeds have the following ratios: first, 3.6 to 1; second, 1.86 to I; top, direct ; reverse, 4.72 to I.

Clutch : This is a Borg and Beck, type FIX 14.

Axles: It is notable that the Voran front axle, which Is the type V, embodies gears supplied by David Brown and Sons, Ltd., of Huddersfield. The ratio of the final drive is 7.25 to 1. A simple dead axle is utilized at the rear.

Chassis Frame: Pressed nickel steel, 5 mm. thick. Dimensions: Wheelbase, 4,600 ram.; track (front and rear), 2,000 mm.; height to top of frame under load, approximately 580 mm.; ground clearance under load, approximately 200 ram. Rear Springing : This is effected by semi-elliptic springs carried in rubber buffer blocks.

Wheels: Fischer cast-steel, spoked type with detachable rims carrying pneumatic tyres. The tyres on both front and rear wheels are medium-pressure 44 in. by 12 in. Continentals.

Brakes: The foot brake takes effect on the tail end of the worm shaft. It is of the loco. type with light-alloy shoes operated by toggle levers. The hand brake acts on shoes in the rear-wheel drums. Both brakes are adjustable from the driver's seat.

Body: The number of seats. provided is 51 and standing room accommodation is afforded for 13 passengers. The maximum overall length is 9,000 nun., the maximum height 3,950 mm., and the maximum width 2,340 mm.

Weights: The total *eight (empty) is 5,600 kilos.; front axle, unloaded, 3,450 kilos. (01.5 per cent of the total) ; loaded, 4,350 kilos. (47 per cent, of the total) ; rear axle, unloaded, 2,150 kilos. (38.5 per cent. of the total), loaded, 4,950 kilos. (53 per cent, of the total) ; engine, including water and oil, about 440 kilos.; change-speed gear and clutch, 160 kilos.; worm-drive casing, 350 kilos. ; chassis, 3,200 kilos. ; body, 2,400 kilos.

One of the advantages of setting back The front axle, as in this bus, is the possibility it affords of fitting a life-guard similar to that used on L.C.C. trams and which has proved so effective on many occasions.

Vertical section of the new Aboag bus body showing stepped upper deck.